The Shakespear Sewing Machine

Figure 2

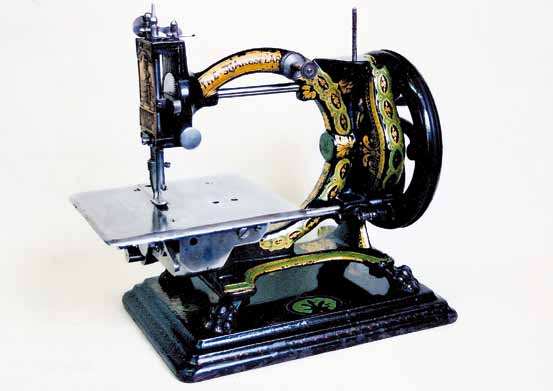

The first version of the 'Shakespear' with a round clothplate

Thomas Shakespear (no 'e' on the end of his name) and George Illston set up the Royal Sewing Machine Co. in 1868 in Birmingham. George Illston ran the factory and Thomas Shakespear looked after sales and marketing.

Their first product was a clone of the Wheeler & Wilson curved-needle machine called the 'Royal'. It was available on a treadle or as a hand machine. In 1872 they moved the works to Herbert Road, Birmingham and the company became a Limited Liability Company in 1877; going into into voluntary liquidation in 1888.

Figure 1

The "Royal", a Wheeler & Wilson clone, was their first production

'Monarch'

A badged 'Shakespear' for Smith & Co.

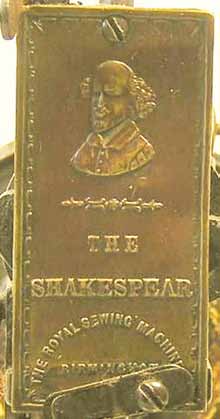

The inscription on the clothplate of the early version

The standard inscription on the later machines

Shakespear & Illston took out a total of five patents for improvements to machines. Their best known hand machine, the 'Shakespear', appeared in 1870 as a small C-frame lockstitch machine retailing at 4 guineas (£4.20). This was the same price as most of its competitors! The 'Shakespear' used a shuttle drive mechanism patented by the pair on March 24th, 1869 (Number 898), and many machines have this stamped on the mechanism. The original machine had a round clothplate but this was soon changed for a rectangular one.

Their advertising took advantage of the confusion in the mind of the customer over Thomas Shakespear, the manufacturer, and William Shakespeare, the playwrght. Various effigies of the bard appeared on the stamped brass frontplates on the machines and the head of the bard over his signature 'William Shakespeare' was used as a trademark by the Company whatever the machine was called.

The William Shakespeare trademark on the balance wheel boss of a 'Shakespear'

The William Shakespeare trademark on a badged machine.

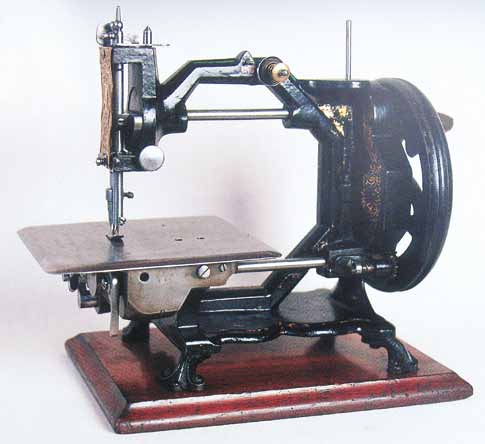

The 'Shakespear' machine was in production for almost the whole life of the Company; from 1870 until the Company folded in 1888. Apart from the change in shape of the clothplate and changes to the design of the brass frontplate, the only significant update was to move the tension discs from half way along the arm to the brass frontplate so that a spring take-up arm could be included to give a take-up arrangement similar to that on the Singer 12K. The frame casting was attached to four individual paw feet which were attached to a wood, or occasionally cast iron, base.

The Royal S. M. Co. manufactured machines and badged them for several other sewing machine factors. The 'Shakespear' itself was sold by Smith & Co., London as the 'Monarch'; only the decals and frontplate being changed.

Shakespear & Illston's patented shuttle drive on the 'Shakespear'

With the clothplate removed

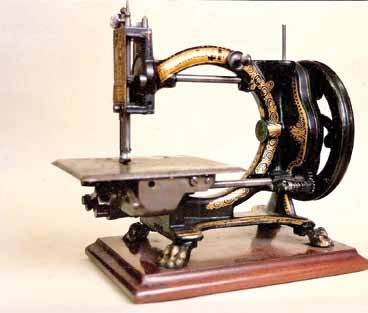

The revised 'Shakespear' with better take-up mechanism. Note the lack of tension discs on the overarm.

The standard 'Shakespear' of the 1870s on a heavy cast iron base

The standard 'Shakespear' of the 1870s on its wooden base

'Collier'

A 'Shakespear' with an octagonal frame (in place of the C-frame) casting

The 'Collier' used a different octagonal frame casting but this was machined to take all the 'Shakespear' mechanical parts.

The 'Challenge', registered by Joseph Harris, was initially manufactured by The Royal S. M. Co for Harris and used the 'Shakespear' mechanics. When Harris joined the Royal S. M. Co. in 1877, the 'Challenge' shape reappeared as the 'Avon', again using 'Shakespear' mechanics on a 'Challenge' shape and a frontplate of the bard.

'Avon'

'Shakespear' mechanics grafted on to a 'Challenge' frame

A later brass frontplate of the Bard

The first version of the brass frontplate

A brass frontplate of the Bard

The 'Avon' frontplate

The brass frontplate of the revised 'Shakespear'

The frontplate of the 'Monarch

The 'Collier' frontplate

Photographs:

Maggie Snell,

Emilio Cano,

and the author