Classes 2 and 3

For Carriage Trimming, Harness Manufacture, etc.

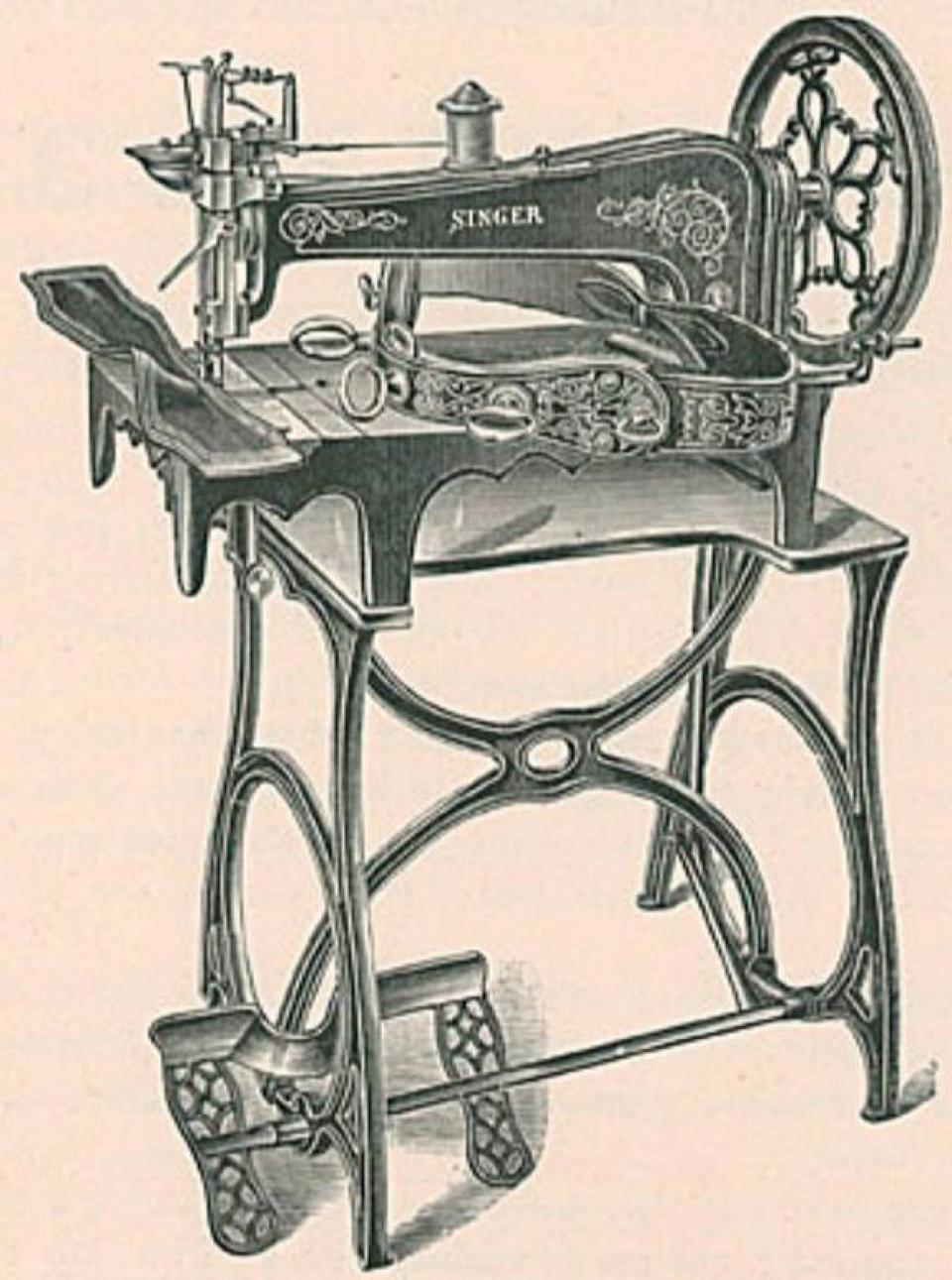

These are the standard lock-stitch machines having reciprocating shuttle for leather work; they are simple, strong and efficient, and were especially designed for and are extensively used by Carriage Trimmers and Harness Manufacturers.

They can be operated either by foot or mechanical power and can be effectively used in a wide range of work in leather, etc. The balance wheel is 13 inches in diameter and its momentum greatly promotes ease of operation and steadiness of motion. All the machines of these classes are provided with powerful Wheel Feed.

Through the excellence of workmanship on these machines and the accurate adjustment of their various parts, great ease of operation is obtained and the wide range of their capacity enables the sewing of either soft or hard material with the greatest facility.

For stitching patent leather and other material having a hard surface difficult to perforate, the machines are furnished with an iron cup to hold a drying oil through which the thread passes.

Boiled linseed oil, mixed with litharge as used by painters, is sometimes used for this purpose; there are also several special preparations in the market.

This method of oiling the thread prevents heating the needle and makes leather stitching as rapid and easy as cloth sewing. The linen thread or silk twist, after being oiled, dries rapidly and its surface becomes as smooth and perfect as if no oil had been used, while the firmness of the seam is improved by such use.

CLASS 2

The machines of Class 2 have a bed IK inches in length, with a clear space of 10 inches from needle to base of arm. They carry a No. 5 reciprocating shuttle and have a large feed-wheel which secures a steady movement of the material.

Machine No. 2-2 is provided with the Singer Vibrating Presser; the movement of this form of presser conforms to the movement and varying thickness of the material so that the top and bottom plies are evenly fed. By its use a uniformly strong and perfect feed is secured in working material having rough, uneven or adhesive surfaces, with soft goods liable to pucker or in stitching around curved edges.

CLASS 3

MACHINE No. 3-1

LARGE SHUTTLE. VIBRATING PRESSER.

The machines of Class 3 correspond in their general design to those of Class 2 but are larger and carry a larger shuttle having correspondingly increased capacity for thread. Their bed is 21 inches in length and there are 1G inches of clear space from needle to base of arm. These machines are especially adapted for Carriage Trimming and Harness work.

Machine No. 3-1 is provided with the Vibrating Presser and Machine No. 3-2 with the Roller-Presser. The roller-presser holds the material down upon the wheel-feed beneath; while it exerts a firm and constant pressure it offers less resistance than the ordinary presser-foot and does not mar the most highly finished surface.

A large number of these machines have been sold and put into successful operation; they are unexcelled for simplicity, durability and efficiency.