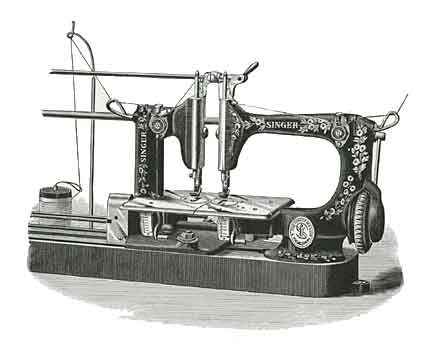

Classes 24, 25 and 26.

THE Chain-stitch Sewing Machines of Classes 24, 25 and 26 have a rotary hook for forming the loop and are distinguished for compactness, high speed, noiselessness and light-running qualities; they are furnished with either Automatic or Plain tension, as desired.

These machines are of the highest type for all purposes in which a single thread chain-stitch can be used; owing to their simple design, the small number of wearing parts and the superior workmanship and material used, they are of remarkable durability and efficiency and attain the highest rate of speed. They are adapted to a wide range of work upon almost every variety of fabric, their capacity under the arm being greater than that of any similar machine.

The frame of the machine is cast in one piece, and is remarkably rigid and free from vibration.

The feed mechanism has a positive motion and the length of stitch is easily adjusted without use of springs.

The Automatic tension device has exceptional excellence; it is so operated that, at each vertical reciprocation of the needle, exactly the correct length of thread is supplied and " slip-stitching" is absolutely impossible.

The stitch is formed from a single thread which is interwoven into a chain on the under surface of the goods; the thread may be drawn closely to the fabric, forming a tight and flat seam, or it may be left in an elastic chain as desired.

A beautiful ornamental stitch, resembling braid, is produced by the use of coarse silk or thread, this feature being of special value and usefulness in the manufacture of Underwear, Hosiery and Knit goods, for ornamenting skirts and draperies, etc.

Modifications of feed dogs, throat-plates and presser-feet are made to suit the various processes in manufacture, such as plaiting, hemming, felling, tucking, gathering, ruffling, binding, quilting, cording, etc., and the machines can be fitted to order with appliances devised to perform each of these operations in the most effective manner.

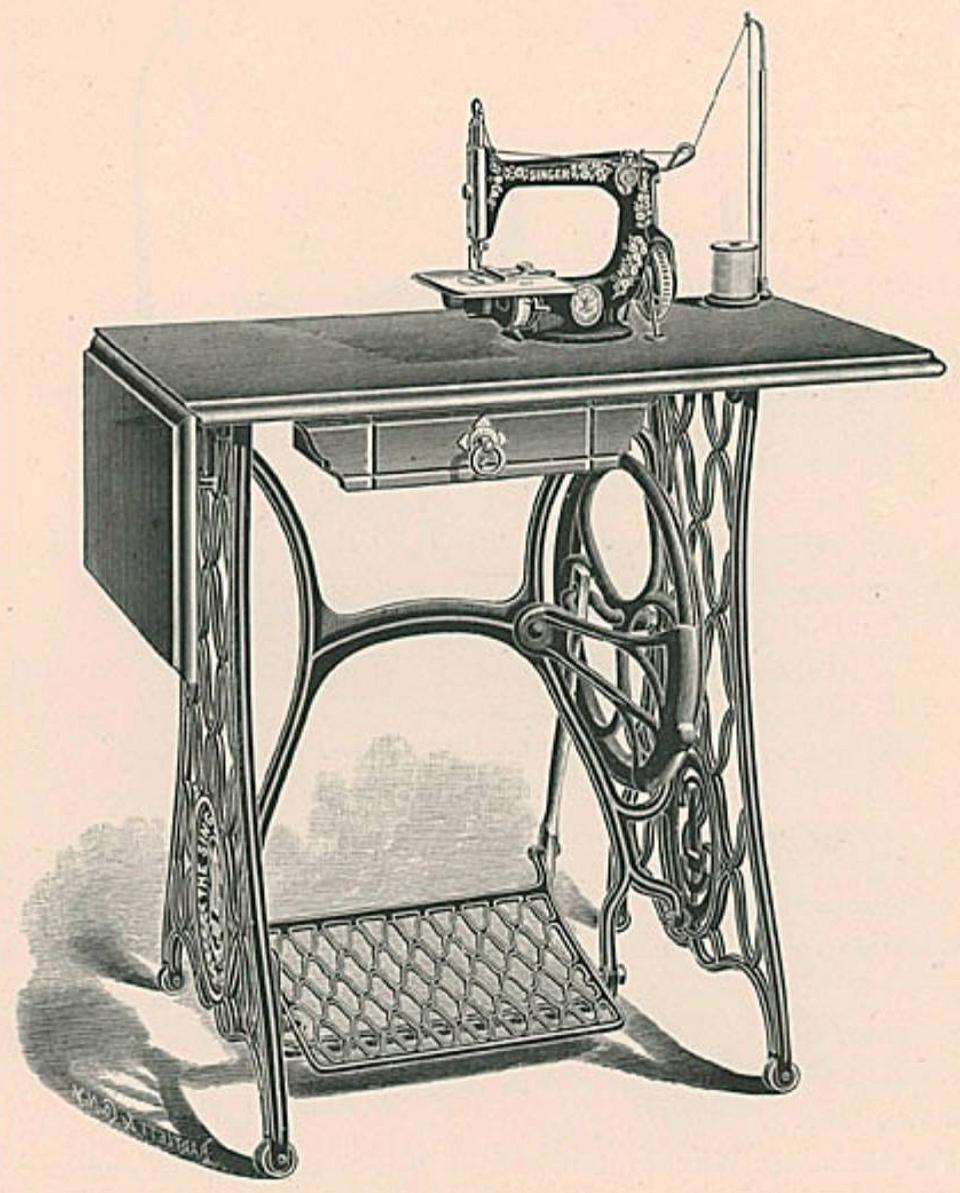

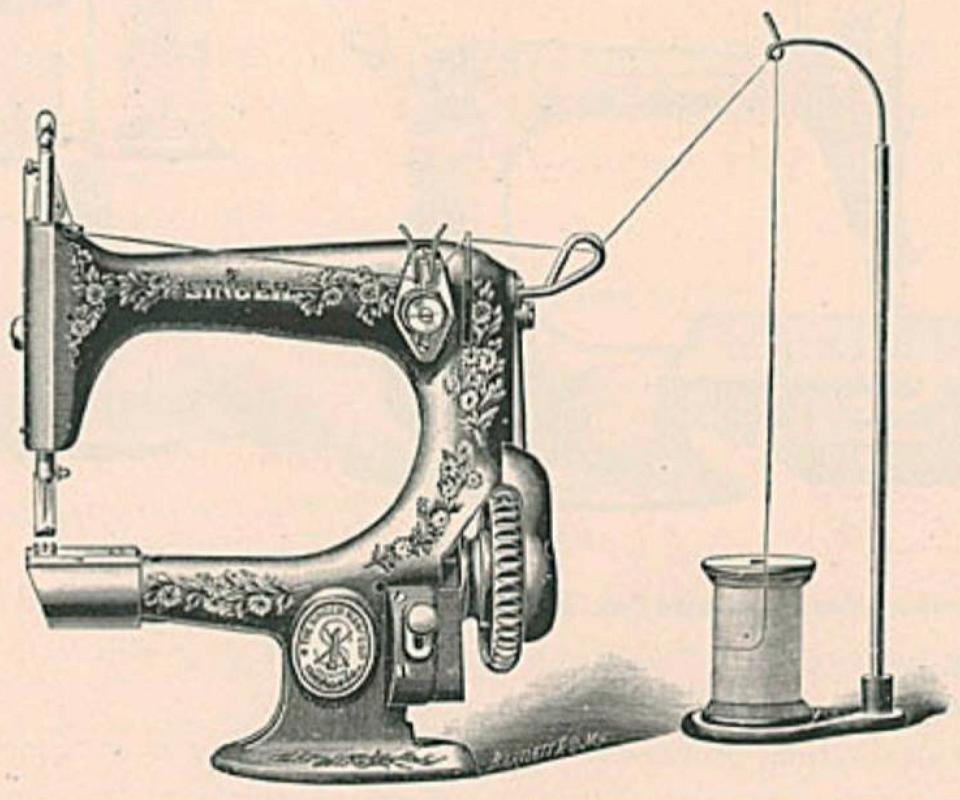

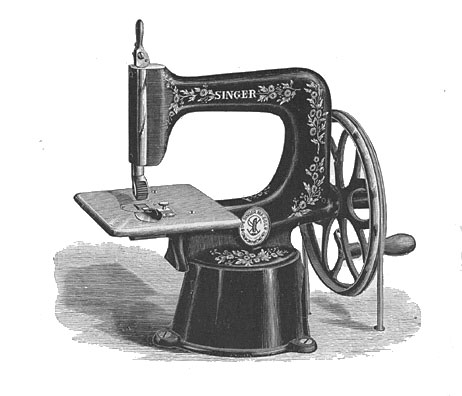

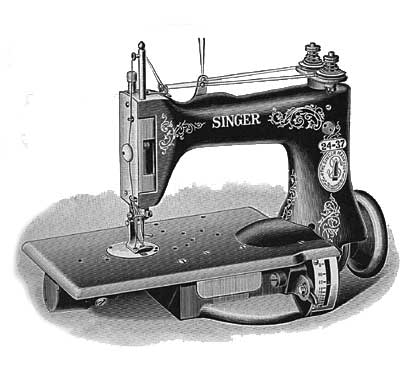

MACHINE No. 24-3

Machine No. 24-3, illustrated above, is especially suited for general manufacturing and is fitted to make from 8 to 30 stitches to the inch; it has the Automatic tension, while Machine No. 24-5 only differs from it in having the Plain adjustable tension device.

Machine No. 24-6 has Plain tension and makes a stitch up to 3/16 inch in length; Machine No. 24-7, Plain tension, makes a stitch up to 1/4 inch in length and is largely used in Hat and Cap manufacture, also for stitching window shades or any work requiring a long and elastic stitch.

The form of stand, shown above, is preferred by operators over all others on account of the ease of its operation and convenience for handling the work.

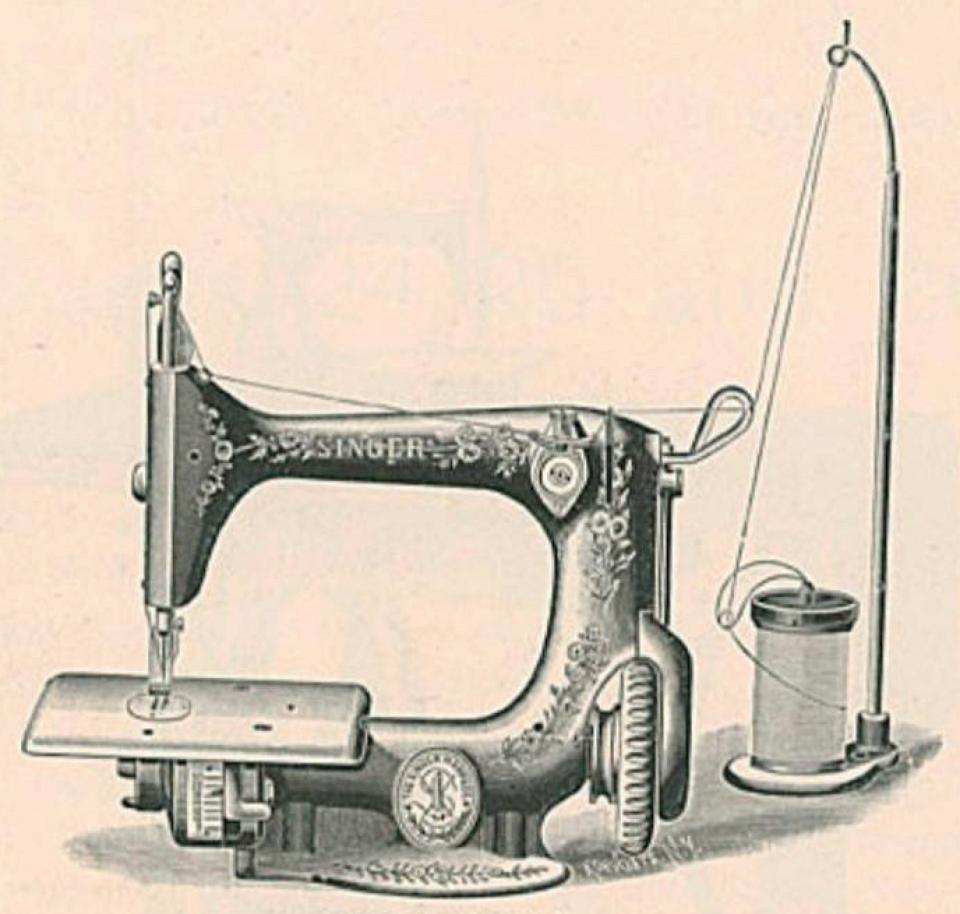

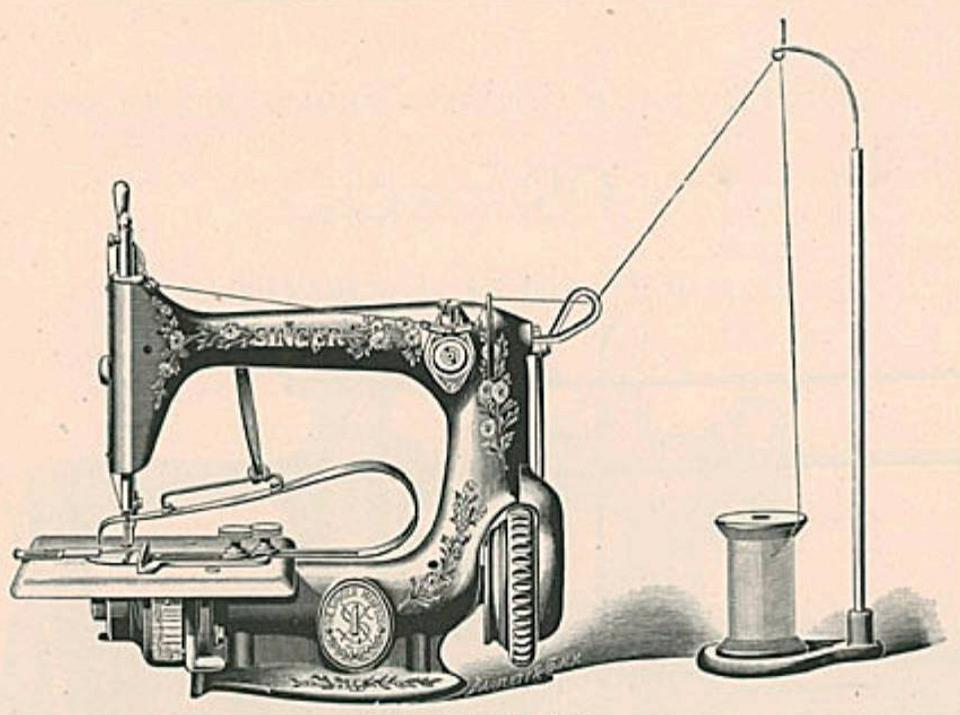

HEAD OF MACHINE No. 24-3

NECKWEAR MANUFACTURE.

In the manufacture of Neckwear the Singer Machine No. 21-3 excels all other chain-stitch machines in the facility with which the stitch can be run closely to the edge of the band, both the lining and face material being uniformly fed. The stitch is carried evenly to the end of one piece of work while operator is preparing the next, and a continuous stitch can be carried from one piece to the other, thus gaining time.

For hemming Windsor ties, etc., a special needle-point hemmer is furnished for making a very narrow hem; the "bias" goods used for this purpose can be hemmed on this machine without stretching, thus securing a wider tie when finished than is possible on other machines.

Should breakage of thread occur, owing to lumps or other accidental causes, the positive action of the Automatic tension prevents catching of thread and drawing the goods down to the looper.

INFANTS' AND CHILDREN'S DRESSES AND BLOUSES.

The high speed, easy operation and excellent work of the Singer chainstitch machines make them the best, not only for ordinary stitching on the above mentioned goods, but the single-needle machine, No. 21-3, is also used for tucking, hemming and ruffling and the two-needle machine, No. 24-8, for attaching braid on children's blouses, making two parallel lines of stitching at once.

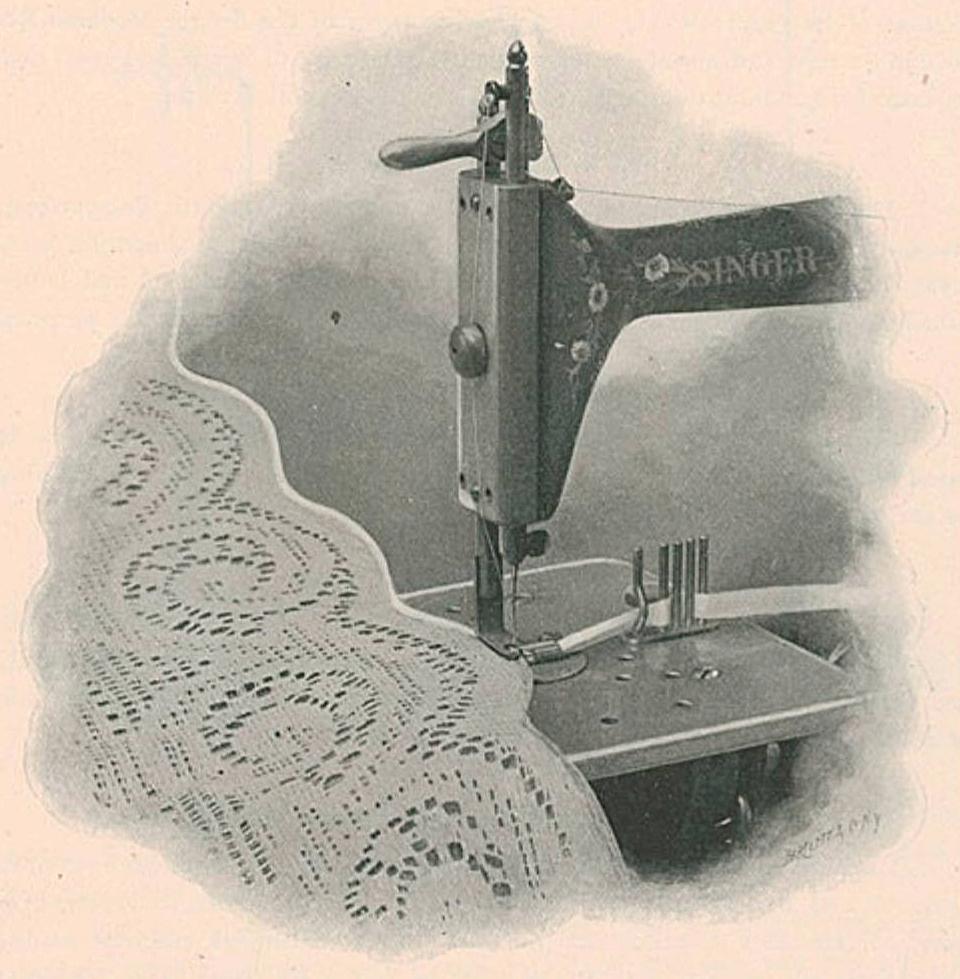

BINDING LACE CURTAINS, ETC.

The above illustration represents Machine No. 24-3 fitted with the "English " binding attachment (No. 210 A. and A.) for folding and delivering tape at exactly the proper point on the work in binding lace curtains and similar material, so that the tape is entirely out of the operator's way. The shape and position of the cloth plate, in combination with the device referred to, secure the greatest convenience in stitching around short scollops or into close angles, while the form and elasticity of stitch are peculiarly adapted for the material and the uses of binding. Another form of binder (No. 215 A. and A.) is arranged to swing into or out of position for work at any instant, as required.

LACE AND RUFFLING GOODS, LADIES' NECKWEAR, RUCHING, ETC.

In the manufacture of these lines of goods the chain-stitch is preferred, because of its elasticity; the manifold advantages of the Singer Machine No. 94-3, in its ease and speed of operation, its perfection of stitch and great convenience for handling this work, cause it to be the general favorite.

INFANTS' LACE CAPS.

The single-needle machine, No. 24-3, is extensively used for fine cording, attaching lace, etc., in the manufacture of Infants' Lace Caps; for inserting wires in the rims of such caps, the two-needle machine, No. 21-8, is used and is furnished with a special presser, making it of the highest efficiency for this purpose.

ORNAMENTED FABRICS, ART EMBROIDERY, ETC.

Machine No. 24-3 is used in the final preparation of these classes of goods, the Automatic chain-stitch being both ornamental and useful for attaching the various parts, for fine trimming, etc.

KNIT GOODS MANUFACTURE.

The chain-stitch is especially desirable in the manufacture of Knit goods on account of its elasticity, the single-needle machine, No. 21-3, being largely used for plain stitching and the two-needle machines, No. 21-4 and No. 24-8, for finishing, binding and staying seams, etc.

UMBRELLA AND PARASOL MANUFACTURE.

Machine No. 24-3 is used in seaming gauzes for all classes of work in Umbrella and Parasol manufacture because of its high speed, convenience of operation, elasticity of stitch and the fact that a continuous stitch is readily carried from one piece of work to the other as fast as the operator can insert it in the simple and efficient folding device. This machine is also used for hemming.

SHOE MANUFACTURE.

The single-needle machine, No. 21-3, is used for closing and linings, while the two-needle machines, No. 24-4 and No. 21-8, are used for making back stays, inside stays, etc.

SILK GLOVE AND MITT MANUFACTURE.

Machine No. 91-4, two-needle Automatic tension, is used for inserting and Machine No. 21-3 for seaming and tips. Manufacturers of silk gloves and mitts appreciate the peculiar fitness of these compact, light and fast running machines, making the elastic stitch essential in this class of work.

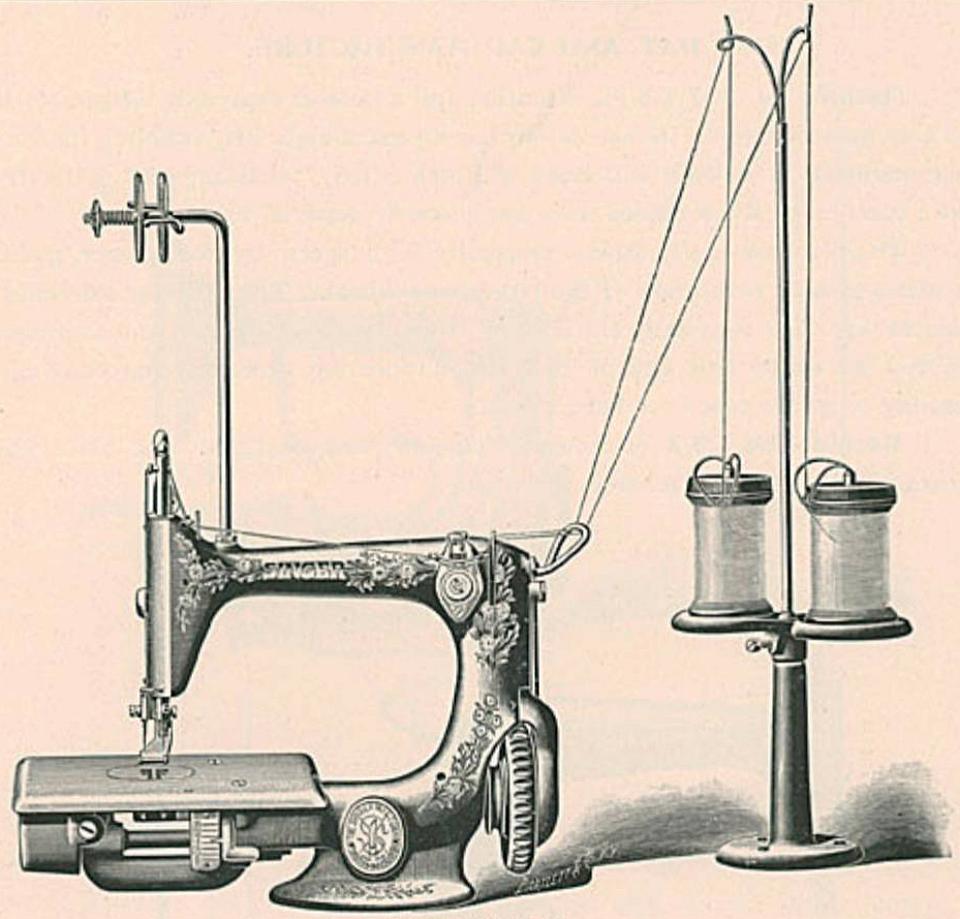

MACHINE No. 24-4

Machines No. 21-4 and No. 24-8 are fitted with two needles and two loopers for making two rows of stitching at once, gauged from 1/16 to 5/8 inch; No. 24-4 has the Automatic tension and No. 24-8 the Plain tension.

For all stitching processes in which elasticity of stitch is of principal importance these machines are unequaled for speed, efficiency and durability and are largely used in the manufacture of Knit goods, Underwear, Umbrellas and Parasols. Silk Gloves and Mitts, etc.

CORSET MANUFACTURE.

The two-needle machines, No. 24-4 and No. 24-8, are used for double-cording, plain strip-stitching, folding and stitching strip at one operation, staying seams with two rows of stitching, etc.

SHIRTS, COLLARS, CUFFS AND MUSLIN UNDERWEAR.

The two-needle machines, Nos. 24-4 and 31-8, are used for inserting shirt bosoms, cording shirt bosoms, re-enforcing shirt fronts, edge-stitching, staying seams, embroidered strip work, etc.

HAT AND CAP MANUFACTURE.

Machine No. 24-7 has Plain tension and a presser especially adapted to Hat and Cap manufacture. Its needle-bar has an extra high lift, enabling its use on thick material, in which it will make a + inch stitch, "chaining off" perfectly so that a continuous stitch passes from one piece of material to the next.

The machine easily attains unusually high speed by foot-power, making S stitches to each revolution of the large band-wheel. The cylinder machines of Class 25 are also especially efficient for rapid stitching in Hat and Cap manufacture, the shape and size of the work-supporting arm enabling convenient handling of goods that have been closed.

Machine No. 25-3 (Automatic tension) and Machine No. 25-4 (Plain tension) make 4 to 12 stitches to the inch.

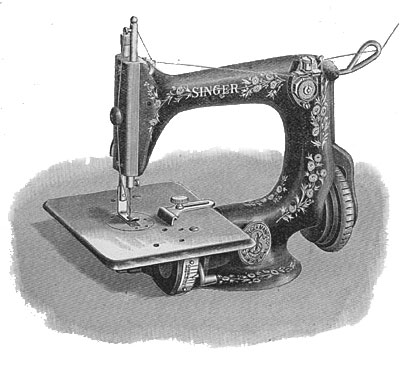

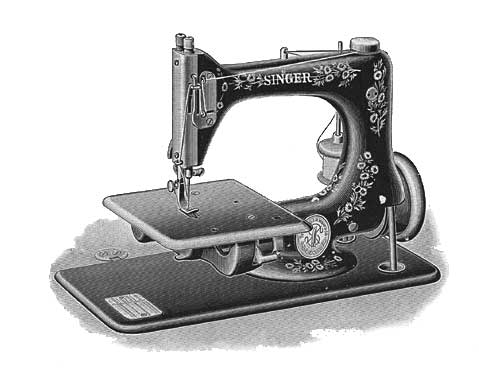

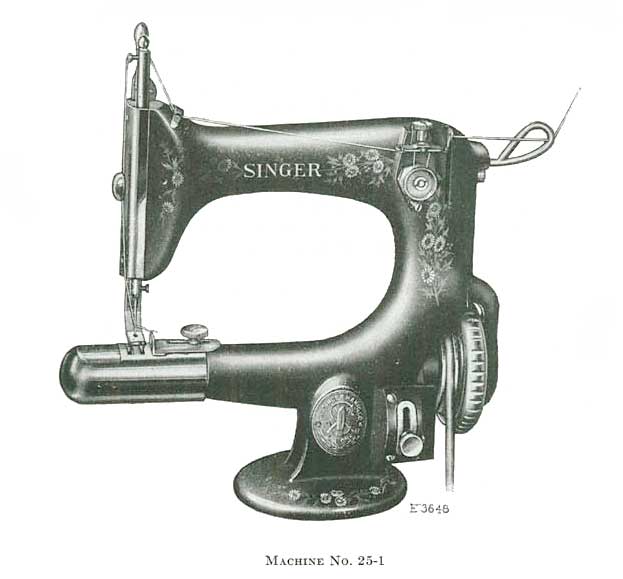

MACHINE No. 25-1

The rotary-hook chain-stitch machines of Class 25 have a cylindrical worksupporting arm specially adapted for hemming gloves, mitts or any other articles of similar form. The arm is of convenient size, being only 14 inches in diameter and measuring 5 inches from needle to base. Machine No. 25-1 has the Automatic and Machine No. 25-2 the Plain tension; these machines make from 8 to 30 stitches to the inch.

Machines of Class 25 can be fitted with an adjustable cloth plate if so ordered; by the attachment of this plate they are practically the same as

Machine No. 24-3, for all purposes where it is desirable to have a flat-bed that is interchangeable for a cylinder.

MACHINE No. 24-11

TUCKING.

Machines Nos. 24-10 and 24-11, having, respectively, the Plain and the Automatic tension, are fitted with a special attachment for tucking, illustrated above; it marks the tuck automatically, making any desired width, and is the most efficient device used for this purpose, its motion not being communicated from the needle-bar, as with other tucking attachments.

GATHERING.

For gathering, especially on lace, Machine No 94-12 is unrivaled; it accomplishes this operation by means of a double feed of peculiar form and having a differential motion which is adjustable. A hinged presser-foot of appropriate shape is provided with a spring which applies sufficient pressure to properly present the material to the action of the feed. Gathering is perfectly done on Torchon lace or other material equally difficult to manipulate, the operation of this machine being unequaled in this class of work.Gathering and stitching to band can be perfectly accomplished at one operation by the use of a special device (machine parts Nos. 9978-9779) furnished for this purpose.

SIDE PLAITING.

Machine No. 24-9 has a special device for folding plaits in the material as it passes under the needle; it is largely used in the manufacture of Shirts, Boys' Waists, etc.

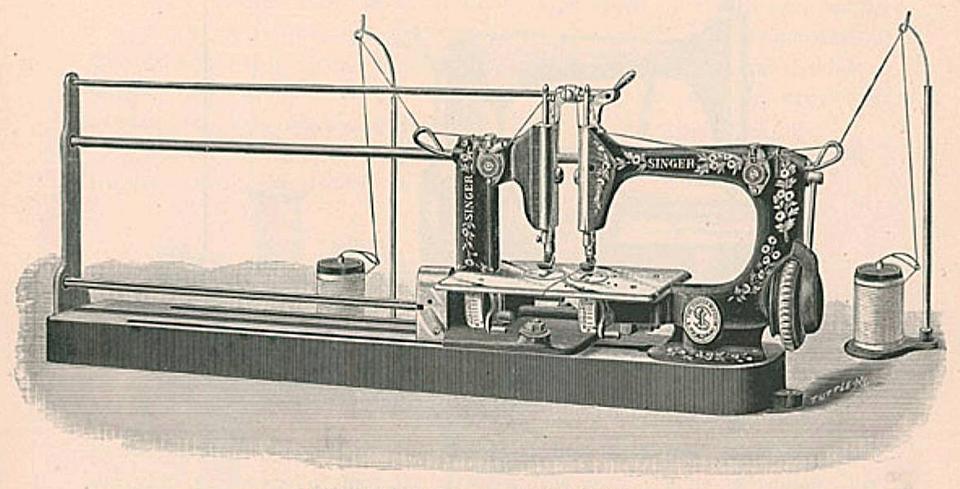

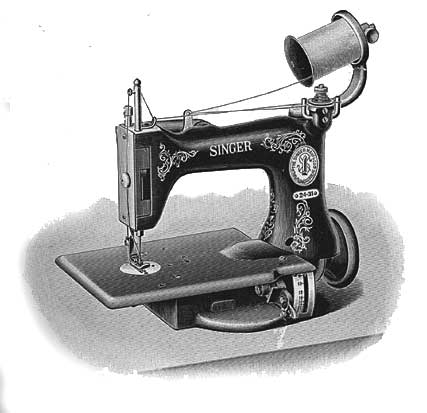

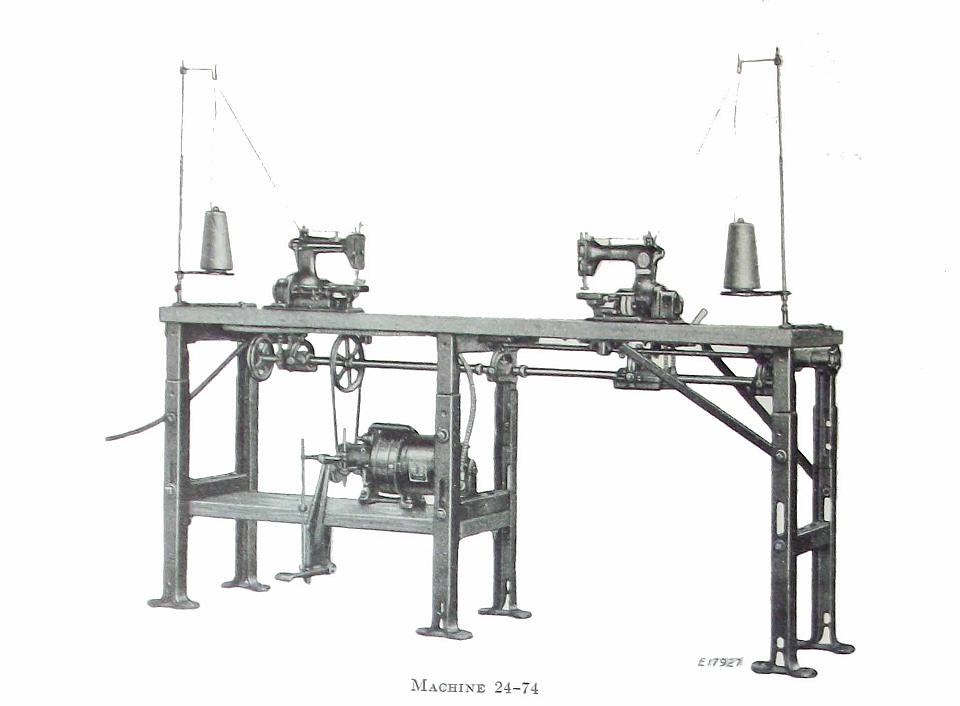

MACHINE No. 26-1

TWO HEADS.

The single-thread chain-stitch machines of Class 26 make two exactly parallel seams at once. They have two heads which are coupled together directly opposite each other, both receiving motion from one shaft and working with exact uniformity.

The least distance between needles, when the heads are together as illustrated, is 2 1/2 inches.

Machine No. 26-1 has the movable head adjustable at will of operator up to a distance of 16 inches between needles, and Machine No. 26-2 is adjustable up to 24 inches.

These machines are especially efficient in stitching the seams of bags and are extensively used in the manufacture of Tobacco Bags, School Bags, etc.

The following is lifted from John Langdon's Comprehensive Model List

| 24W (class) | Industrial | Vertical rotating sewing hook with stationary bobbin case mechanism for making the lock stitch simultaneously in two parallel seams at high speed in a variety of fabrics and leather. with depressed beds and offset throat plates. | ||

| 24W1 | Industrial | 128x13 or 128x3 (3303) | ||

| 24- (class) | 1900-60 | Industrial & Domestic | Chain stitch. Some, mostly hand crank models, were 'domestics'. | |

| 24K (class) | 1897 to post-1943 | Industrial & Domestic | As class 24. Some hand crank models were 'domestics' | |

| 24-3 | Industrial | Automatic tension. 8-30 stitches to the inch. | 24x1 or 24x2 | |

24-4

|

Industrial | For two row stitching. Two needles. Two loopers. Automatic tension. 8-30 stitches to the inch. | 24x3; 24x1 or 24x2 | |

| 24-5 | Industrial | Plain tension | 24x1 or 24x2 | |

| 24-6 | Industrial | For stitch up to 3/16" long. Plain tension. Speed 2000 spm | 24x1 or 24x2 | |

24-7

|

Industrial | For caps and similar articles (for general stitching). Clearance under presser foot 1/4". Plain tension. 4-12 stitches to the inch. Speed 2000 spm. (In catalog 09/1951) | 24x1 or 24x2 | |

| 24-8 | Industrial | As 24-4 but with plain tension. For two row stitching. Speed 2500. | 24x3; 24x1 or 24x2 | |

| 24-9 | Industrial | Automatic tension. Side plaiting attachment. Knee lifter. | 24x1 | |

| 24-10 | Industrial | Plain tension; with power tucker. | 24x1 | |

| 24-11 | Industrial | Automatic tension; with power tucker. | 24x1 | |

| 24-12 | Industrial | Adjustable gathering feed. | 24x1 | |

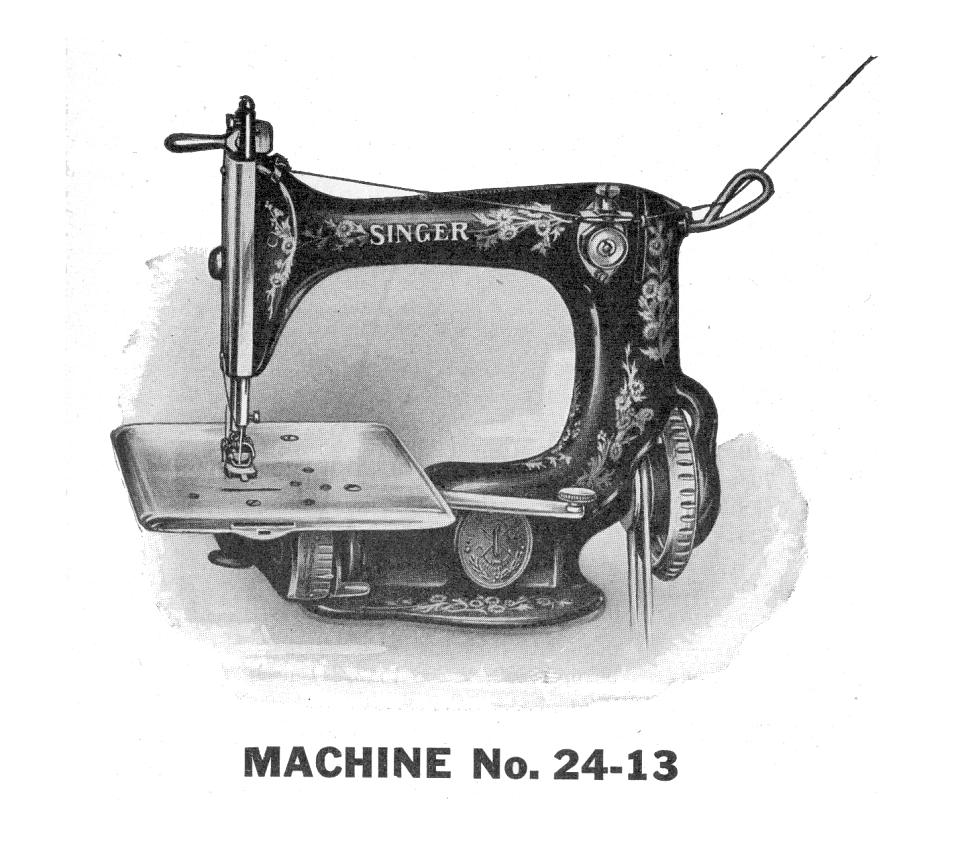

24-13

|

Industrial | For gathering. Has lever for adjusting the fullness of gathers. Automatic tension; adjustable feed; fitted with an adjustable gathering feel for gathering at high speed, light material for infants' wear, aprons, dresses, etc. Speed 2500 spm | 24x1 | |

| 24-14 | Industrial | For tucking. Positively driven power tuck marker driven by link from arm rock shaft. Fitted with a special tuck marking attachment for tucking aprons, dresses, infants' wear, etc. Automatic tension. Speed 2500 spm | 24x1 | |

| 24-15 | Industrial | For making plain, box, or double box pleats in strips up to 3/4" wide. | 24x1 | |

24-17

|

Industrial | NO STITCHING MECHANISM. For folding and crimping the edges of fabrics. | 24x1 | |

| 24-18 | Industrial | Automatic measuring tension; adjustable for tight or loose stitches. For umbrella seaming and imitation spoke stitching. 8 to 30 stitches to the inch. | 24x1 | |

24-19

|

Industrial | Fitted with a plaiting attachment for making knife plaits, single, double and triple plaits. Also for making plain, box, or double box plaits across, not lengthwise. Plain tension. Speed 1000 spm | 24x1 | |

| 24-21 | Industrial | For two row stitching. Two needles. Two loopers. Plain tension. 4 to 12 stitches to the inch. Speed 2500. | 24x3; 24x1 or 24x2 | |

| 24-22 | Industrial | Plain tension. For making plain or box overlapped plaits in strips or ribbons. For edge work only. Stitches across the plaits | 24x1 | |

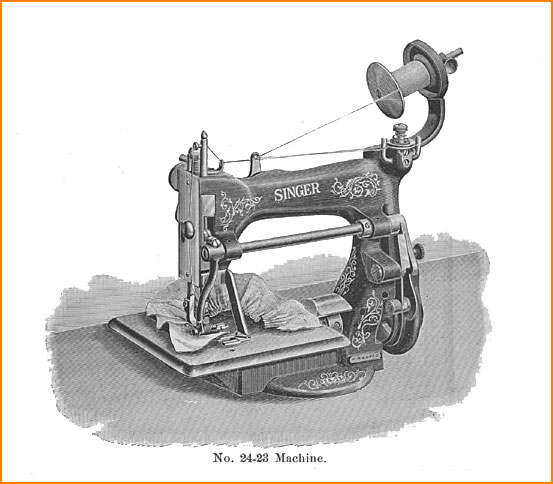

24-23

|

Industrial | For full or scant ruffling on either edge of the goods. Has right and left hand guides; separator blades; positive ruffling mechanism for ruffling aprons, dresses, infants' wear, shirts, wrappers, underwear, etc. Plain tension. Speed 2000 spm. (In catalog 09/1951) | 24x7 | |

| 24-25 | Industrial | Automatic tension with device for plaiting and finishing ladies' belts. Speed 1800. | ||

| 24-26 | Industrial | For stitching in fabrics. 8 to 30 stitches to the inch. Automatic tension. Speed 2500 spm. (In catalogue 09/1951) | 24x1 | |

| 24-27 | Industrial | Plain tension; positive ruffling mechanism. For full or scant ruffled scallops of strips or ribbons 5/16" to 5/8" wide. 8 stitches to the scallop. For millinery and novelty trimmings. | 24x7 | |

24-28

|

Industrial | Plain tension; positive ruffling mechanism. For full or scant ruffled scallops of strips or ribbons 7/16" to 1" wide. 16 stitches to the scallop. For millinery and novelty trimmings. | 24x7 | |

| 24-29 | Industrial | For full or scant ruffling on either edge of the goods. Two needles; two loopers. Has right and left hand guides; separator blades; positive ruffling mechanism. Plain tension. | 24x1 (1111) | |

24-31

|

Industrial | Speed 2000-2500 spm Plain tension Stitch length 8 to 30 SPI. For stitching in fabrics. | 24x7 | |

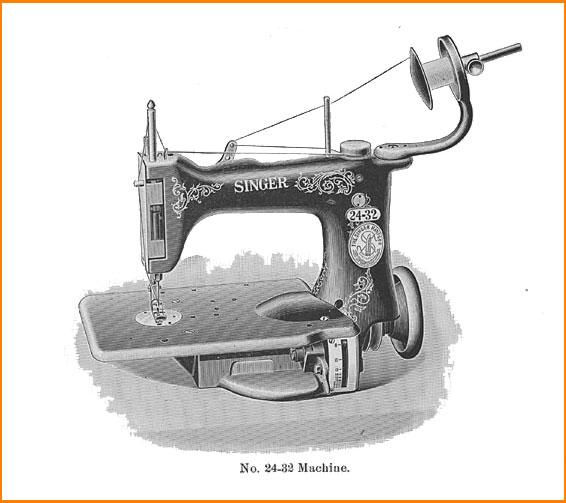

24-32

|

Industrial | As 24-31 but with automatic tension. Speed 2500 spm. (In catalog 09/1951) | 24x7 | |

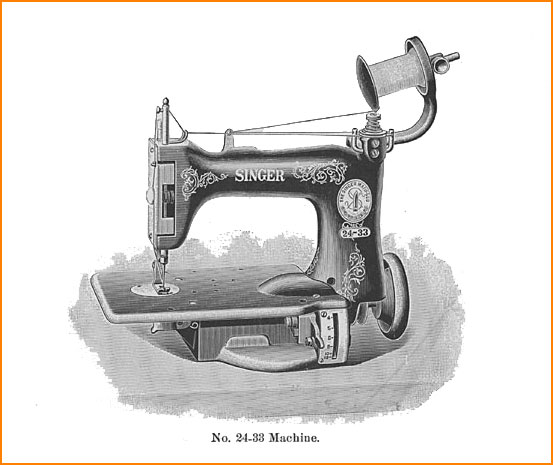

24-33

|

Industrial | Plain tension. Heavy arm and bed. For cap work, etc. 4 to 12 stitches to the inch. Speed 2000 spm | 24x7 | |

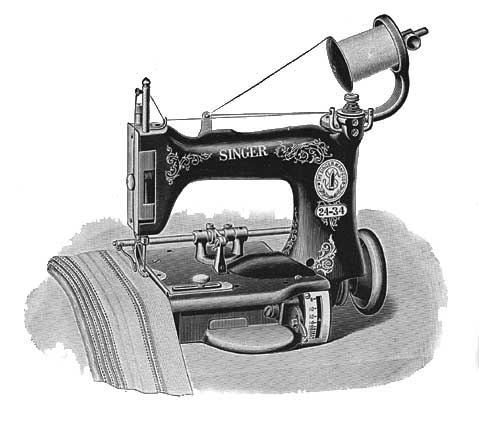

24-34

|

Industrial | Special tuck marking attachment for tucking aprons, dresses, infants' wear, etc. Speed 2500 spm | 24x7 | |

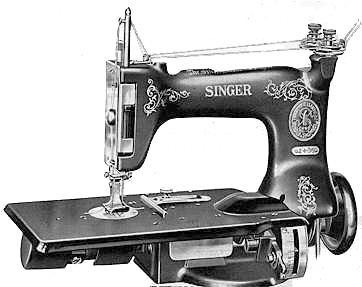

24-36

|

||||

24-37

|

* | Industrial | For two row stitching. Two needles and two loopers. Automatic tension. 8 to 30 SPI. *(In catalog 09/1951) | 24x3; 24x1 or 24x2 |

| 24-38 | Industrial | For tucking. Positively driven power tuck marker driven from looper shaft. Automatic tension. Speed 2500. | 24x7 | |

| 24-39 | Industrial | For seaming, imitation spoke stitching, etc., in the manufacture of umbrellas and parasols. Speed 2500 spm | 24x7 | |

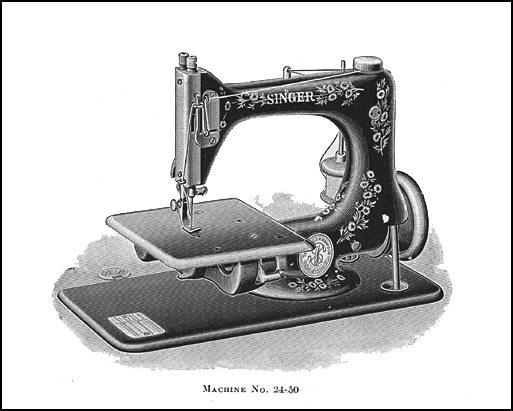

24-50

|

Domestic | Automatic tension. | 24x1 | |

| 24-51 | Domestic | Automatic tension; with hand attachment. | 24x1 | |

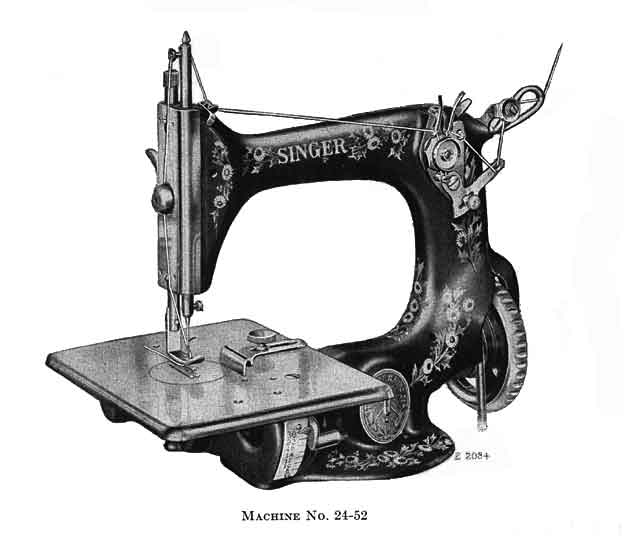

24-52

|

Industrial | For seaming, imitation spoke stitching, etc., in the manufacture of umbrellas and parasols. Speed 2500 spm | 24x1 (1111) | |

| 24-53 | Industrial | Speed 2500 spm For forming and stitching picot edging upon casket linings, curtains, draperies, etc. | 24x1 (1111) | |

24-54

|

Industrial | For forming and stitch picot edging on lace curtains, millinery goods and novelty trimmings. Speed 2000 spm | 24x1 (1111) | |

| 24-55 | Industrial | Two needles and two loopers. Plain tension. 8 to 30 SPI. Speed 2500. For covering and reinforcing the inside seams of cloth caps with a folded strip. | ||

| 24-56 | Industrial | Speed 3200 spm For use in the manufacture of caps. All sizes of caps from the smallest to the largest are easily handled as bed can be made wide or narrow. | 24x1 (1111) | |

| 24-57 | Industrial | For making linings for women's hats. With combination attachment which folds bias strip to form piping into which a cord may be inserted, while the gathering feed gathers the side of the encircling strip, the whole being simultaneously stitched to the crown of the lining. Speed 2000 spm | 24x1 (1111) | |

24-60

|

Domestic | For family use. Automatic tension. | 24x1 | |

| 24-61 | Domestic | For family use. Automatic tension. | 24x1 | |

| 24-62 | (Obsolete by 1931) | Domestic | For family use. B. T. Motor and metal base plate; for portable set No. 202 with knee controller. | 24x1 |

| 24-63 | (Obsolete by 1931) | Domestic | For family use. For B. T. motor with foot control. To be used on cabinet table and foot power stand | 24x1 |

| 24-65 | (Obsolete by 1931) | Domestic | For family use. B. U. Motor. With Singerlight and metal base plate; for Portable Set; with knee control. For portable case set 202. | 24x1 |

| 24-66 | Domestic | As 24-62 but with B.U. motor; different base. Carbon knee control etc. Portable set 205. | 24x1 | |

| 24-67 | Domestic | As 24-62 but with B.U. motor; different base. Carbon knee control etc. Cabinet table set #40. | 24x1 | |

| 24-72 | Head only (movable) - for use with 24-74. Single needle. Length of stitch 4 to 12 to the inch. (In catalog 07/ 1953) | |||

| 24-73 | Head only (stationary) - for use with 24-74. Single needle. Length of stitch 4 to 12 to the inch. (In catalogue 07/ 1953) | |||

24-74

|

TWO HEAD machine for hemming or binding both edges of side walls of mattresses and goods such as curtains, drapes,etc. in one operation. (In catalog 07/ 1953) | |||

| 24-80 | Domestic | Single thread chainstitch; auto tension | 24x1 (1111) | |

| 24W105 | (Cancelled 07/38) | Singer suggested replacement 112W145. | ||

| 24W107 | (Cancelled 1955) | Singer suggested replacement 112W139. | ||

| 25TC | 1990 | Domestic | Straight lockstitch. "15 class motorized in a bentwood case". Black. | 15x1 |

| 25- (class) | Industrial | Cylinder bed (mostly), 1 5/16" diameter. 5" space at right of needle. Single thread; chain stitch. Rotating hook. | - | |

25-1

|

Industrial | For light fabrics. Automatic tension. 8 to 30 SPI. Speed 2500. | 24x1 or 24x2 | |

| 25-2 | Industrial | For light fabrics. Plain tension. 8 to 30 SPI. Speed 2500. | 24x1 or 24x2 | |

25-3

|

Industrial | Automatic tension. 4 to 12 SPI. Speed 2000. | 24x1 or 24x2 | |

| 25-4 | Industrial | Plain tension. 4 to 12 SPI. | 24x1 or 24x2 | |

| 25-6 | Industrial | Automatic measuring tension; adjustable for tight or loose stitches; 8 to 30 SPI. | 24x1 or 24x2 | |

| 25-51 | Industrial | Single thread chain stitch; rotating hook; plain tension, Speed 2500. For stitching straw braid in straw hat work. (As 25-50 but balance wheel is uncovered). | 25x1 | |

26-1

|

Industrial | Two separate sewing machines coupled together to work in unison. Rt. hand machine fixed; left hand machine is adjustable relative to it - from 1 1/2" to 16". Automatic tension. Speed 2000. For making bags for tobacco, flour, seeds, etc. | 24x1 | |

| 26-2 | Industrial | As 26-1 with widest distance between needles (between machines) increased to 24". | 24x1 | |

| 26W | Industrial | Vertical rotating sewing hook with stationary bobbin case mechanism for making the lock stitch simultaneously in two parallel seams (gauges = 3/4" to 2 1/4") at high speed in a variety of fabrics and leather. Speed 2000. | - | |

| 26W100 | (Cancelled 07/33) | Singer suggested replacement 112W145. | ||

| 26W102 | (Cancelled 07/33) | Singer suggested replacement 112W139. | ||

| 26W103 | Industrial | For sewing on labels. Speed 1000. | 126x1, 126x3, 128x1, 128x2, 128x3, 128x4, 128x5. 128x6, 128x7, 128x9, 128x11, 128x13, 128x20, 129x1, 129x2, 129x3, 129x5, 129x6, 132x1, 132x2 | |

| 26W106 | (Cancelled 04/1924) | Industrial | Singer suggested replacement: 24W105 | |

26W107

|

(Cancelled 08/48) | Industrial | ||

| 26W108 | (Cancelled 04/1924) | Industrial | Singer suggested replacement: 24W107 |