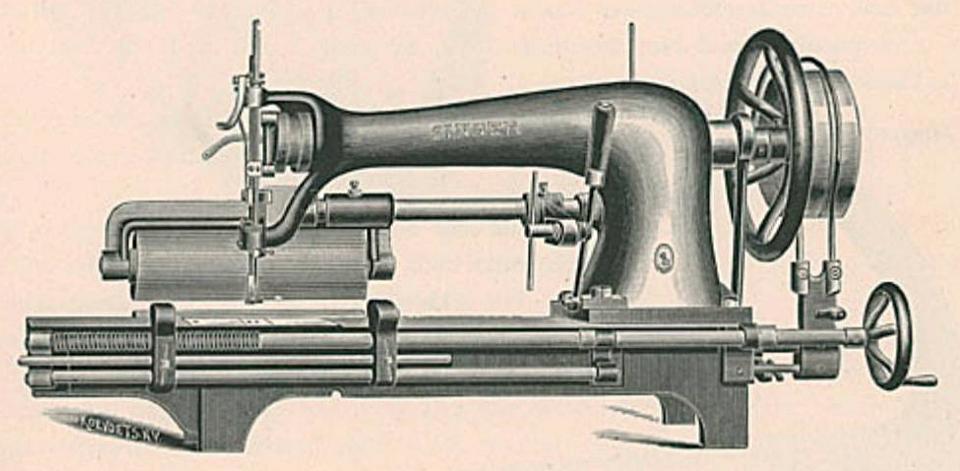

Class 5

Adjustable Driven Feed-Rolls, for Mechanical Power.

MACHINE No. 5-3

OPERATED BY MECHANICAL POWER.

MACHINES OF CLASS 5.

Several varieties of Class 5 are made, but all are provided with Adjustable Driven Feed-rolls, which draw the material through Adjustable Guides and under a flat or a roller-presser, as may be desired. 'The Feed-rolls may be driven by either a clutch or a ratchet, the latter method being employed in the machine illustrated. The extreme length of the bed is thirty-two inches, and the clear space on the bed from needle to base of arm is nineteen inches. The machines of this class will stitch to the centre of a belt thirty-eight inches in width. Two forms of guides are made, and the machines may be fitted with either as desired; one form is arranged to slide on a round rod, the other is operated by means of a screw, as illustrated. Each full turn of the hand wheel at the end of the screw-rod moves the guide one-quarter of an inch.

Machine No. 5-1 has feed-rolls driven by ratchet, has either flat or roller. presser, as desired, and is provided with sliding guides. Power is received by flat belt running over tight and loose pulleys of 14-inch face, having belt shifter.

Machine No. 5-2 has feed-rolls driven by a clutch, but in all other respects is the same as No. 5-1.

Machine No. 5-3 has feed-rolls driven by ratchet, has either flat or roller- presser, as desired, and is provided with screw-guide, tight and loose pulleys and belt shifter.

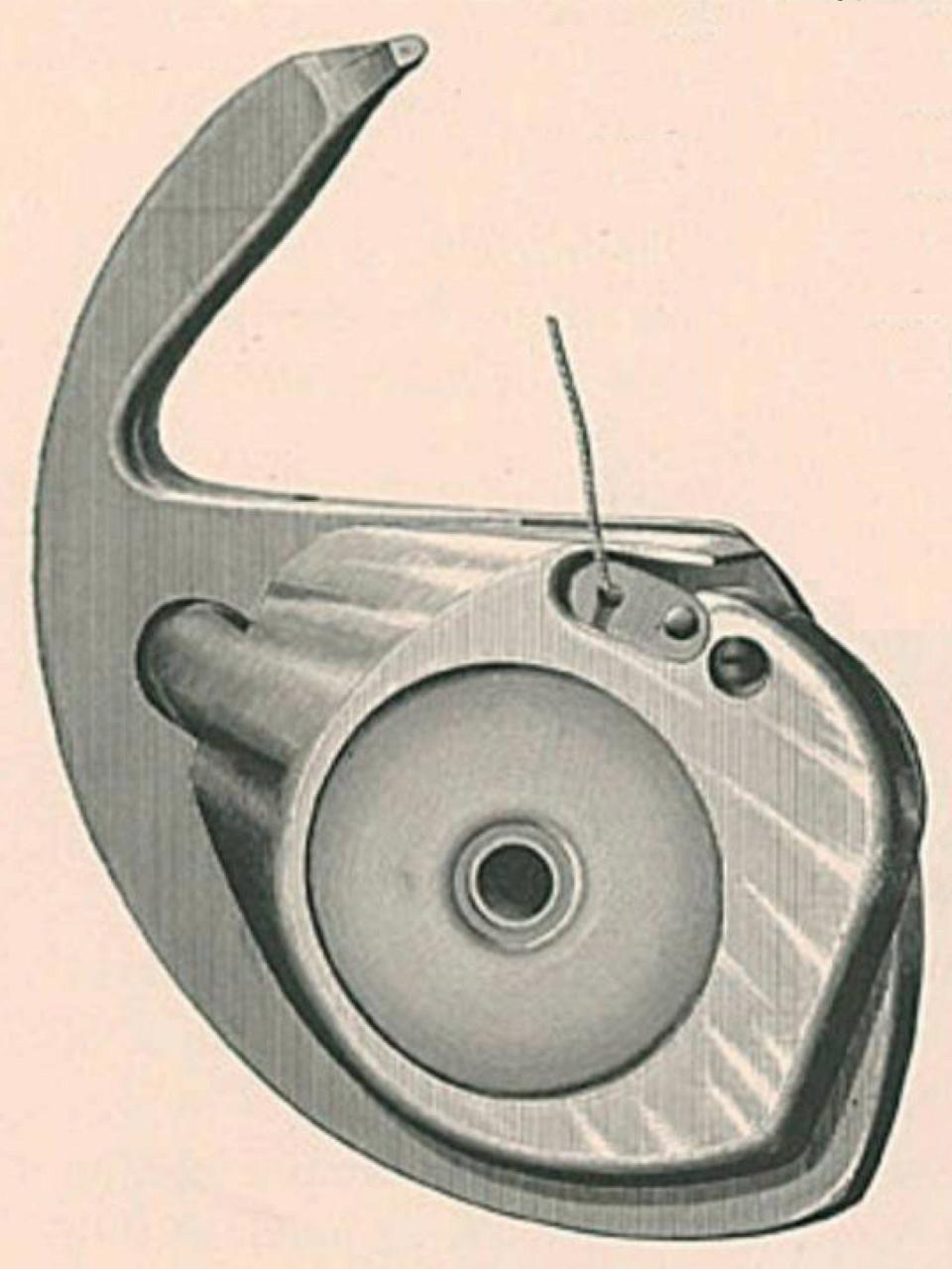

Machine No. 5-4 has feed-rolls driven by clutch; otherwise it is driven the same as No. 5-3. The Shuttle is of the oscillating-cylinder type provided with very large bobbin, having great capacity for coarse thread.

The length of stitch is adjustable through the motion of the feed rolls, and has a range up to one-half inch; the motion of the thread take-up is so regulated, in conjunction with the oscillation of the long-beak shuttle, as to enable the use of thread large enough to fill the needle hole so that a perfect stitch of the greatest strength is obtained.

TWO-NEEDLE MACHINES.

All of the machines in Class 5, carrying variety numbers from 5 to 8, inclusive, are of the twin-needle type for simultaneously making two parallel rows of stitching; each carries two needles on one needlebar and is provided with two shuttles.

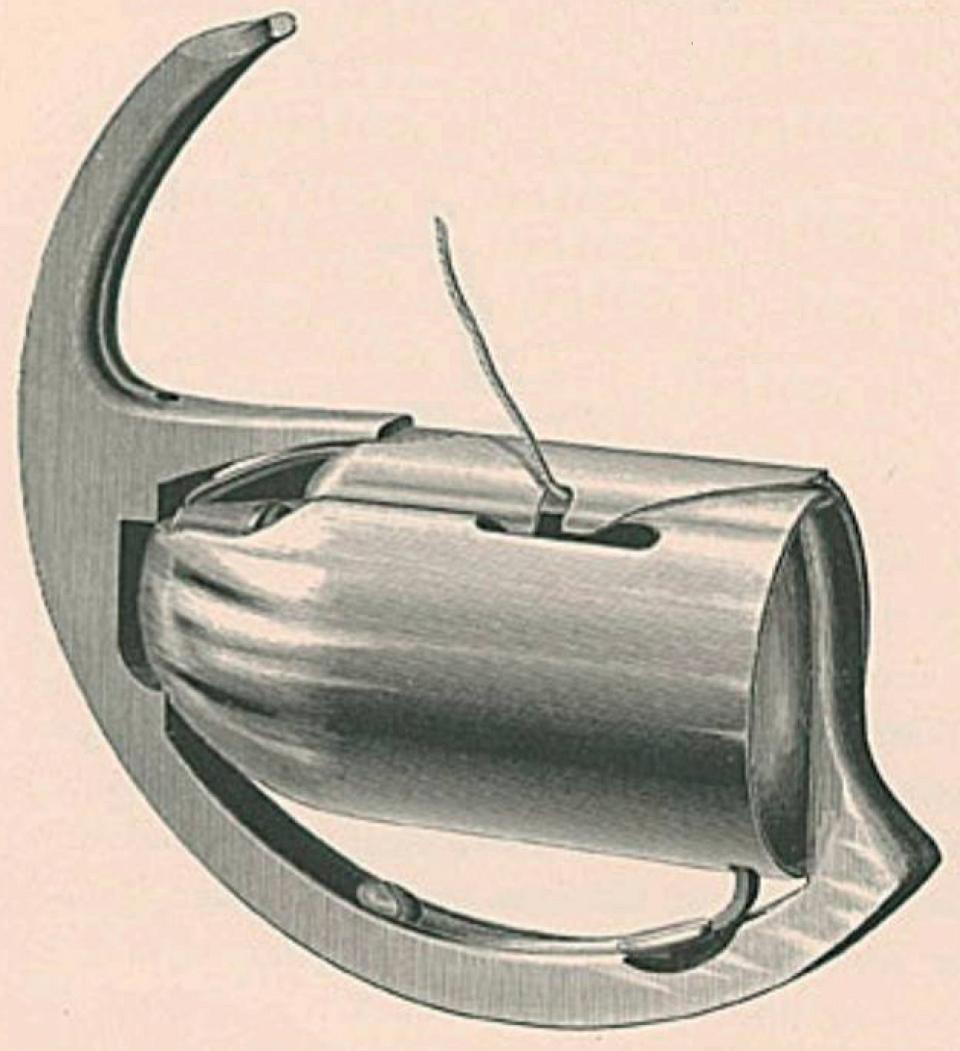

Machines No. 5-5 and No. 5-6 are arranged to stitch parallel rows either one-half inch or three quarters inch apart, as ordered, the feed-rolls of No. 5-5 being driven by a ratchet and those of No. 5-6 by a clutch. Two Box-shuttles of the size illustrated in the margin are used in these two varieties of this class.

Machines No. 5-7 and No. 5-8 can be gauged to make the rows of stitching either 1 inch, 14 inches or 14 inches apart, as ordered. Two Cylinder-shuttles of the size illustrated on the preceding page are used in these two varieties of this class.

THE OVERSEAMING MACHINE.

Machine No. 5-9 performs straight stitching, and also makes the overseaming or zig-zag stitch. The Needle-bar is carried in a pivoted frame, producing a reciprocating motion from side to side.

The length of side throw of the Needle-bar is adjusted by means of a pitman in front of the arm. When the adjusting thumb-screw on this pitman is set at the lower extremity of the slot in which it moves the needle has no vibrating motion, and a straight stitch results; when fastened at the top the full length of throw is obtained, making an overseaming stitch three-eighths of an inch wide.Within these extremes a great variation in the form of the stitch may be effected.

The extreme length of stitch is one inch, and the machine is readily adjusted to make any shorter length by means of the mechanism controlling the movement of the feed-rolls; this mechanism can be either a Clutch or a Ratchet, as previously explained.

The Shuttle is of the Oscillating-cylinder type, and carries a large bobbin having a great capacity for thread.

The following is lifted from John Langdon's Comprehensive Model List

| 5K (class) | *1897-1925 | Industrial | Bed 32 1/2"; Extension to left 9"; 19" from needle to base of arm. *Some shown as produced in 1893/4 | |

| 5-1 | Industrial | Roller feed driven by ratchet, roller or flat presser, sliding gauge with set screw and belt shifter. | 5x1 | |

| 5K1 | 1897-1925 | Industrial | Reciprocating shuttle. 19 1/2" to right of needle. For canvas, leather and rubber or any other material for belts up to 40" wide and 7/8" thick. | 202x1 |

| 5-2 | (Obsolete 1912) | Industrial | Roller feed by ratchet, roller or flat presser, sliding gauge with set screw and belt shifter. | 5x1 |

| 5K2 | 1897-1925 | Industrial | Reciprocating shuttle. 19 1/2" to right of needle. Two needles and two shuttles For belting, (5" rolls); gauge from 5/8" to 1 1/2". | 202x1 |

| 5-3 | * | Industrial | Same as 5-1 but with screw guide and associated parts. Ratchet feed. *(Still in catalog 09/1951) | |

| 5K3 | Industrial | Reciprocating shuttle. 19 1/2" to right of needle. 8" rolls. For canvas, leather and rubber or any other material for belts up to 40" wide and 7/8" thick. | ||

| 5-4 | Industrial | Same as 5-2 but with screw guide. Clutch feed. | 5x1 | |

| 5K4 | Industrial | Reciprocating shuttle. 19 1/2" to right of needle. 8" rolls. Two needles and two shuttles 8" rolls. For belting, | ||

| 5-5 | Industrial | Two box shuttles. 1/2" to 15/16" Guage, ratchet feed, screw guide. | 5x1 | |

| 5-7 | * | Industrial | Same as 5-3 but with two needles and two cylindrical shuttles; guages 1" to 1 1/2". Ratchet feed, screw guide. *(In catalog 09/1951) | 5x1 |

| 5-9 | Overseaming or zigzag machine. Needler throw <3/8". Ratchet feed. | |||

| 5-10 | Industrial | Same as 5-1 with different guide rod. Ratchet feed. Greatest distance from centre of needle bar to inside of right hand guide 17 inches. Sliding guide with special spring catch. | 5x1 | |

| 5-11 | Industrial | Same as 5-7 and 5-10 but with different guide and guide rod parts. Two cylinder shuttles. 1 inch to 1 1/2 inch guage. Ratchet feed. Sliding guide with special spring catch. | 5x1 |