Class 37.

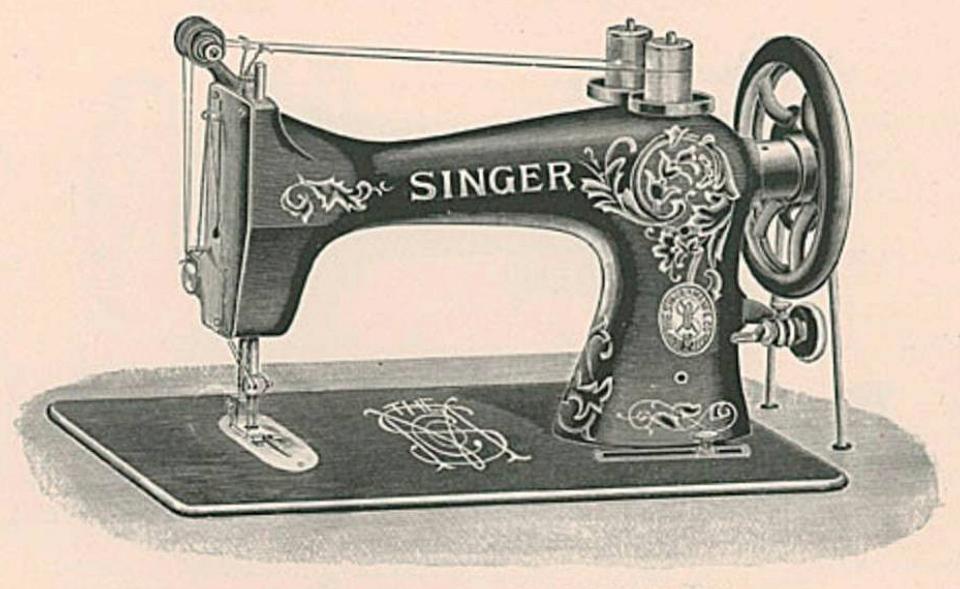

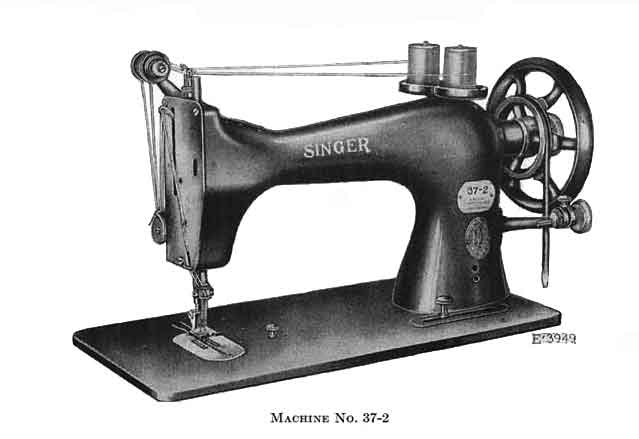

MACHINE No. 37-2

FOR STAY STITCHING.

Bed 15 3/4 inches in length, 7 1/2 inches from Needle to Base of Arm.

THE machine illustrated above is of the highest efficiency for staying seams in Shoes, Clothing, etc., without the use of tape or any reinforcement other than the strong flat stay-stitch made across the under side of the seam.

The advantages of this process have been demonstrated by practical use; it secures a stronger, more elastic and more durable seam than any other method of staying and accomplishes it at less cost.

This machine has drop-feed and the needle-bar carries two needles which make two parallel rows of stitching, one on each side of the seam; the loops from both rows are drawn across the seam on the under side of the fabric and are strongly united by the action of a vertical oscillating shuttle carrying a Central Bobbin with capacity for one hundred yards of No, 60 cotton.

The distance between needles can be gauged as ordered, up to an extreme width of three-sixteenths of an inch.

The presser-foot shown in the above illustration has a tongue corresponding to a groove in the throat-plate, for receiving the edges of the fabric.

This machine can also be furnished with a presser-foot having a groove corresponding to a tongue in the throat-plate, for raising the face of the material so as to present the appearance of cording, for use on Shoes, the backs of Gloves, etc.; it can also be fitted with a cord-guide in the throat-plate so as to insert a cord on the under side of the material, where it is held in position by the cross-stitch from the shuttle thread.

MACHINE No. 37-3

FOR HAT SWEATS

This variety of Class 37 is fitted especially for stitching, at one operation, a reed into the glaze for Hat Sweats, and attaching both reed and glaze to the edge of the leather without marring the material by feed marks; it has proved, in practical operation, to be of the highest efficiency for its special purpose.

There is no under-feed, the movement of the material being obtained through the action of the vibrating top-feed mechanism specially adapted for the work.

The sweat is fed with its face down; the glaze is attached to the back of the sweat and is automatically folded over the reed as both are drawn through an attachment on the bed of the machine directly in front of the needles.

The needles are placed diagonally, the vertical oscillating shuttle operates at a corresponding angle, so that the angular stitch on the face of the sweat has the appearance of hand-sewing, with the advantages of greatly increased production, uniformity and strength of stitch.

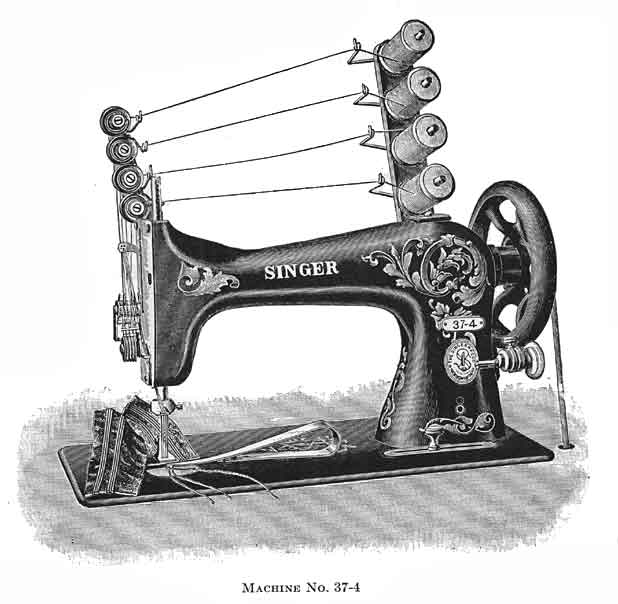

MACHINE No. 37-4

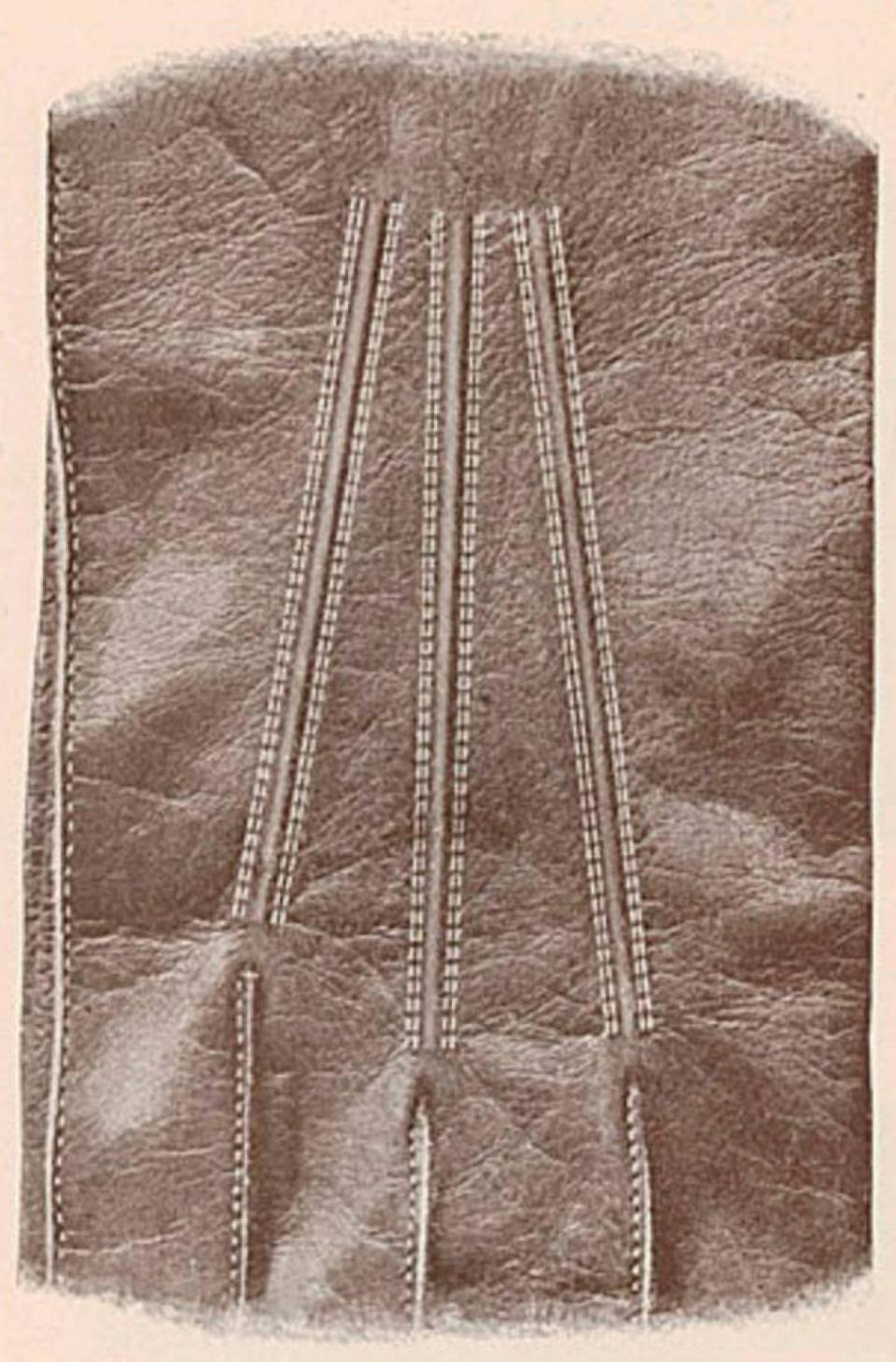

FOR STITCHING GLOVE-BACKS.

The four-needle machine of Class 37, for ornamenting the backs of gloves, has proved, in practical operation, to be of the highest efficiency in point of economy of operation and the finished appearance of its work. The marginal illustration is a photographic reproduction of the work of this machine on a kid glove. Four parallel seams are sewed simultaneously with the use of but one under thread, the work being of a superior character, :and effecting a decided saving in cost of silk and labor.

For Cording Shoe Tips, the machine can be used for inserting and stitching either one, two or three rows of cord, in one operation, as desired.

Folding and Cording Muslin Strips. In the manufacture of corded strips for trimming Underwear, Infants' Clothing, Lace Caps, etc., this machine is fitted with special folding and cording attachment for folding the strip and inserting four rows of cord in one operation.

The following is lifted from John Langdon's Comprehensive Model List

| 37- (class) | Industrial | Central bobbin. One vertical shuttle, but fitted with two or more needles. The needle threads are interlocked by the shuttle thread forming two or more straight lines of stitching on the upper side, and an overseam (stay stitch) on the under side. 7 1/2" space at right of needle. | - | |

37-2

|

Industrial | Two needles. Drop feed. Speed 1200. For staying or cording. | 16x73 or 16x74, 16x85 or 16x86 | |

37-3

|

Industrial | Two needles, diagonal stitch. Has attachment for folding and sewing bias strips with inserted reed upon the edges of sweats in one operation. Upper feed. Speed 1200. For hat sweats. | 16x73 or 16x74, 16x85 or 16x86 | |

37-4

|

Industrial | Four needles, knee lifter, drop feed. Speed 1200. For cording and plain stitching. | 16x74 or 16x86, 19x2 and 19x4, 19x6 and 19x8, 37x2 or 37x4 | |

| 37-6 | Industrial | Four needles, knee lifter, drop feed. Speed 1200. For cording. | 16x74 or 16x86, 19x2 and 19x4, 19x6 and 19x8, 37x2 or 37x4 | |

| 37-8 | Industrial | Two needles, drop feed. Speed 1200. | 16x73 or 16x74, 16x85 and 16x86, | |

| 37-10 | Industrial | As 37-3 but makes the diagonal stitch reversed. Speed 1200. For hat sweats and glove backs. | 16x73 or 16x74 |