Class 33.

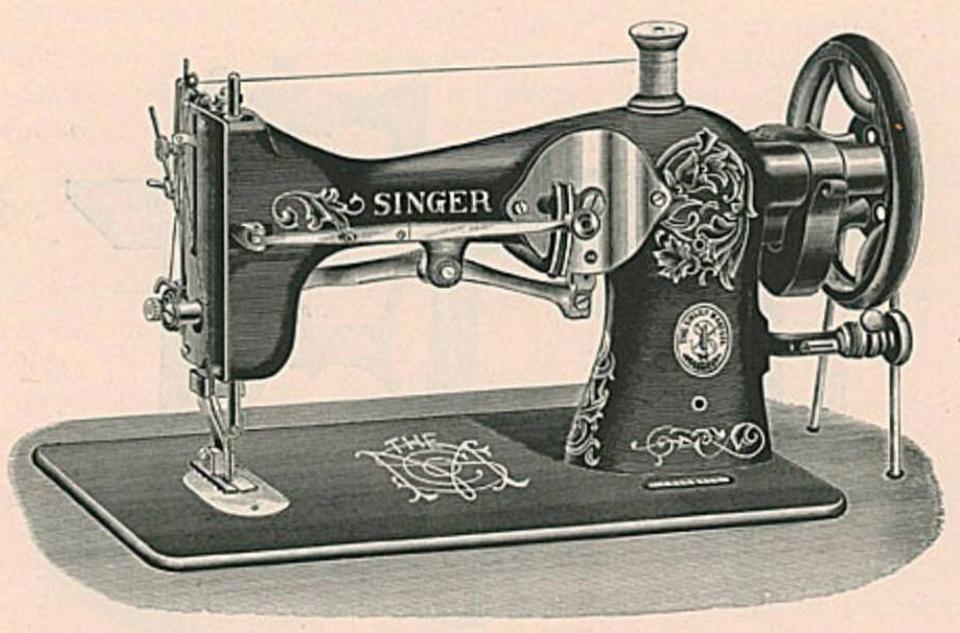

MACHINE No. 33-1

FOR HEM-STITCHING.

Bed 15 3/4 inches in length, 7 5/8 Inches from Needle to Base of Arm.

Oscillating mechanism, Central Bobbin. Vertical Shuttle.

THIS is our latest production for its special purpose and is the result of practical experience and careful experiment with a view to over. coming all mechanical obstacles heretofore met in performing this difficult class of work on a sewing-machine.

This device, in actual factory operation, has demonstrated the efficiency of its simple mechanism to be the highest both in the quantity and quality of its product, the facility of operation and its durability. It perfectly performs both "SHIRE" and "IMITATION HEM-STITCHING." the respective processes being explained as follows:

Those threads that run longitudinally from end to end of the fabric are called the warp, and those threads that cross and intersect the warp are called the weit.

In "Shire" or Thread-drawn Hem-stitching if, for instance, an inch hem is desired on a handkerchief, from three to six or eight of the warp or weft threads are drawn from the fabric two and one-quarter inches from its edge, the number of threads drawn depending upon the quality of the material and the width of "shire" desired; then turn over about one-quarter of an inch on the edge of the goods and bring the edge thus folded up to the edge of the drawn threads, press down the fold thus made and proceed to sew; the action of the needle gathers as many threads of the drawn space together as the stitch regulator is set for, and fastens them at each stitch.

In "Imitation" Hem-stitching the material is folded as in "Shire" Hemstitching, but without drawing either warp or weft threads, the folded material is placed beneath the presser-foot, and stitching is performed as in "Shire" work.

The action of the needle is the same, both warp and weft threads being gathered together and fastened with the stitch the same as in " Shire" work.

This machine received the only Medal and Diploma awarded at the World's Columbian Exposition in this class of machines, the International Jury specifying the superior excellence of its top-feed having peculiar intermittent and reverse action that co-operates with a horizontally reciprocating needle-bar and needle to most effectively form hem-stitching having every appearance of the finest hand work. There being no under-feed, the opening in the throat-plate is quite small, just sufficient for the play of the needle.

The ingenious feed-mechanism carries the goods straight and true; the sectional presser is adjustable so that uniform pressure is applied at the folds on one side the stitch and the single web on the other, thus obviating puckering and carrying a seam that is always even at the end. The feed-movement, lateral throw of the needle-bar and the timing of the shuttle are capable of the finest adjustment so that absolutely perfect work is obtained with less trouble than on any other machine.

ATTACHING BEAD TRIMMING.

The upper-feed mechanism peculiar to this machine, in combination with the overseaming stitch, make it especially effective for attaching strung Bead Trimming in the ornamentation of Cloaks, etc. It can be specially fitted for this work, the strung beads being taken from a bobbin or reel and guided through a tube so that they are delivered on the fabric close to the needle, and can be securely stitched in an intricate pattern having short curves, circles ОГ angles, as desired.

The following is lifted from John Langdon's Comprehensive Model List

| 33 (class) | Industrial | Hemstitch. C.B. vertical shuttle; drop feed. 7 5/8" space to right of needle. | - | |

| 33K (class) | 1893-(1940?) | Industrial | Clydebank-made 33 class. | |

| 33-1 | Industrial | For "revere" stitch. Speed 1200. | ||

| 33-5 | Industrial | For fine hemstitching. With awl and plunger. Speed 1200. | 33x5 | |

| 33-8 | Industrial | For hemstitching with attachment for tucking at the same time. | 33x5 | |

| 33-9 | Industrial | For "revere" stitch with attachment for tucking at the same time. Speed 1200. | 33x1 | |

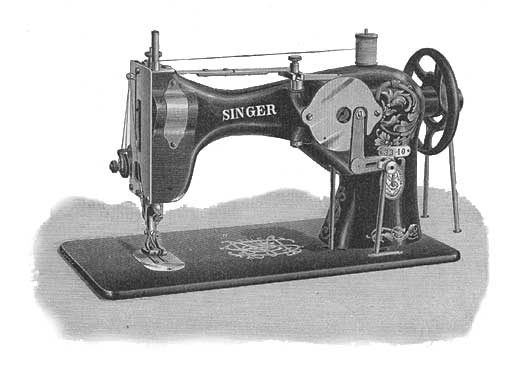

33-10

|

Industrial | For fine hemstitching. High speed (1600). | 33x5 | |

| 33-11 | Industrial | For fine hemstitching and tucking at the same time. Knee lifter. | 33x5 | |

33-12

|

Industrial | For fine hemstitching in light and fine materials; high speed (1600) two awls - one in front of needle, one behind. Knee lifter. | 33x5 | |

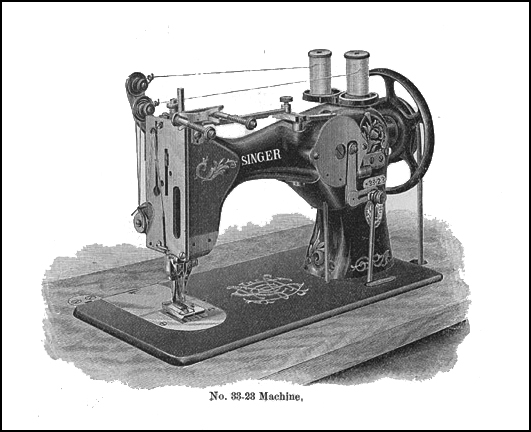

33-23

|

Industrial | |||

| 33K57 | Industrial | Drop feed; for "rider's edge stitch" on thread drawn work | 33x1 |