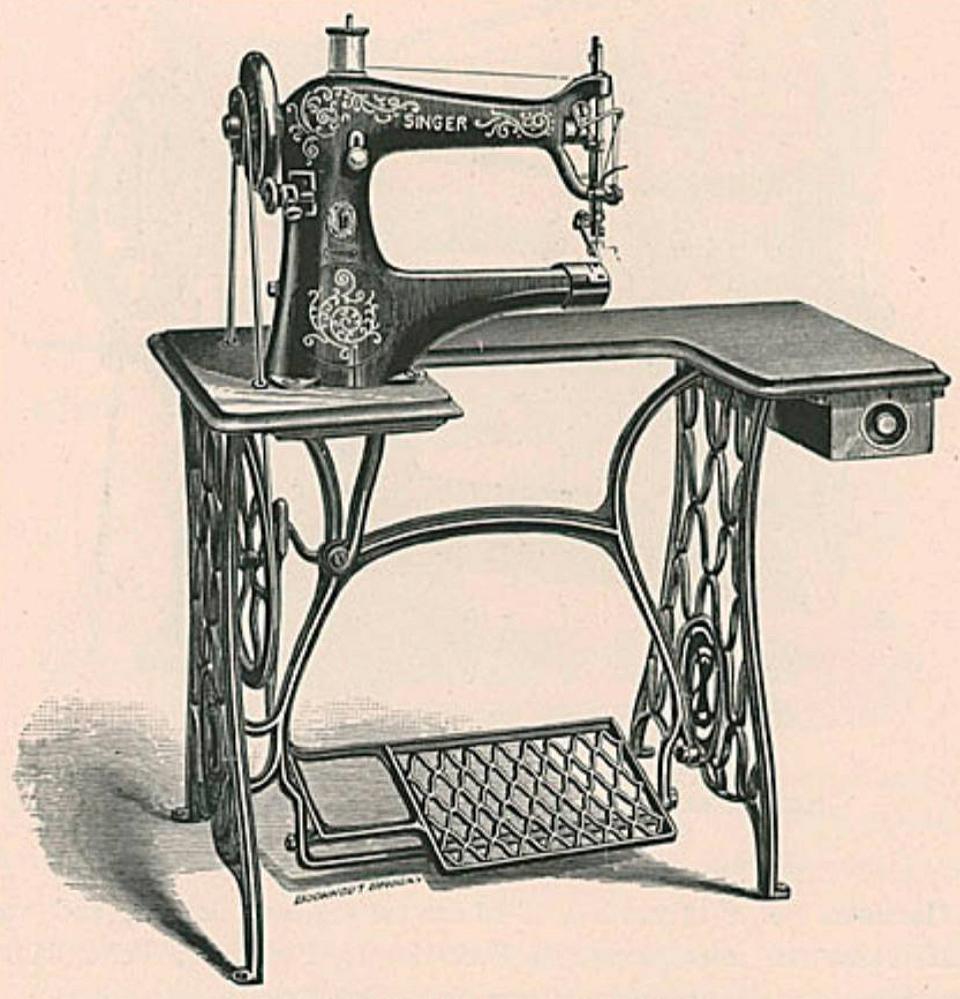

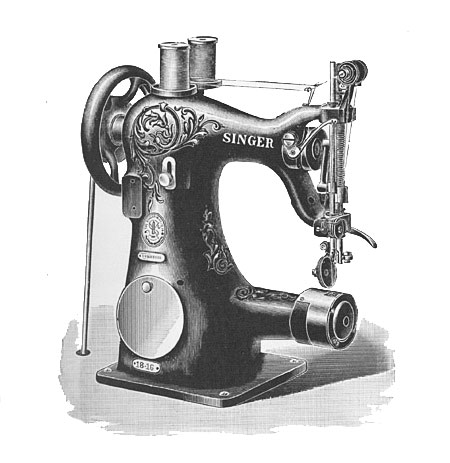

Singer Class 18 Industrial Sewing Machines

MACHINE No. 18-1

ON STAND.

THE machines of Class 18 have a cylinder bed or work-supporting arm for the convenient handling of articles having a tubular or concave form; the bed measures 16 inches in length, 10 1/2 inches from needle to base of arm, and 2 1/2 inches in diameter, excepting machine No. 18-7, which has a bed 2 inches in diameter.

These machines are distinguished for strength and stability, the arm and bed being cast in one piece. This method of construction enables operation at high speed without vibration.The balance wheel is at the left of the operator and the feed motion is across the arm; the machines of this class have the Oscillating Shuttle mechanism, are light running, using either foot or mechanical power, and are especially adapted for Shoe Vamping or similar stitching.

Machine No. 18-1, having drop-feed at right of needle, is generally used for stitching the quarter over the vamp; Machine No. 18-2, having drop-feed, and

Machine No. 18-3, having wheel-feed, both feeds being at left of needle, are used for stitching the vamp over the quarter.

Machine No. 18-7 has drop-feed at left of needle and the diameter of cylinder-bed is only two inches, enabling its use on Children's Shoes and other articles having small opening.

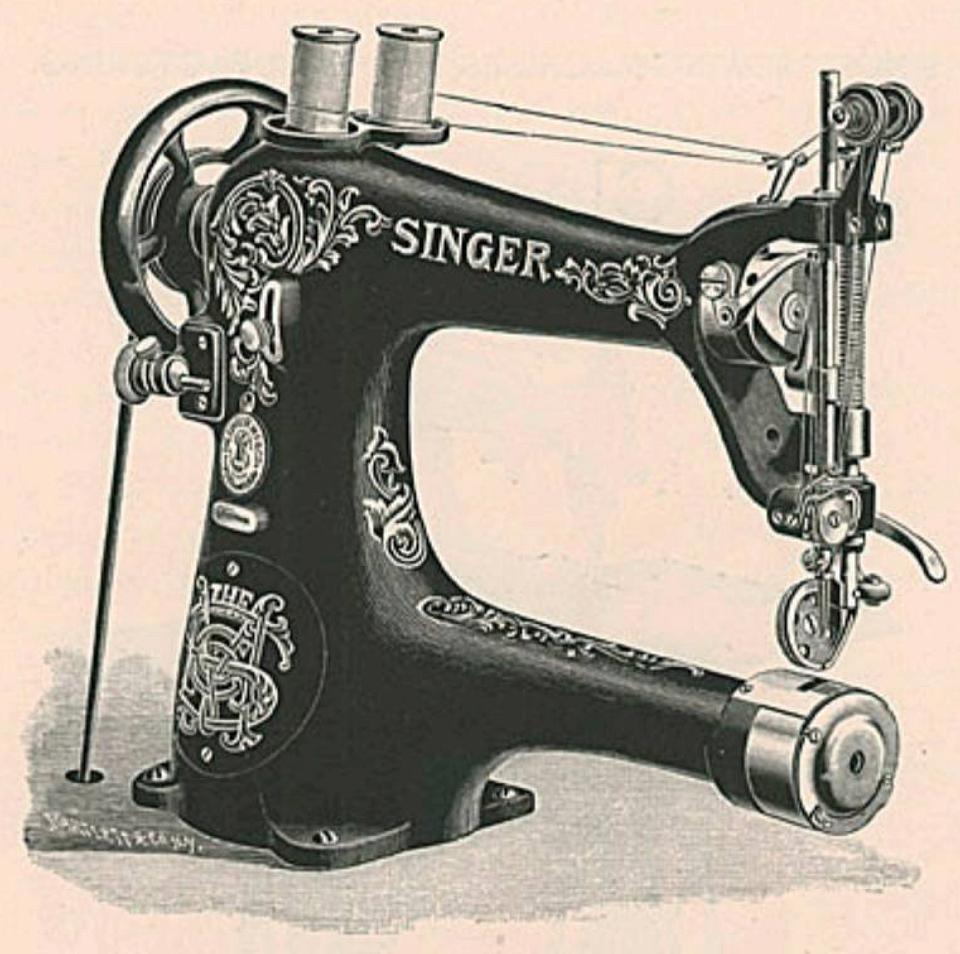

MACHINE NO. 18-5

TWO SHUTTLES

FOR VAMPING SHOES. ETC.

The machine illustrated above has a cylinder bed or work-supporting arm 24 inches in diameter, inclosing two oscillating shuttles which operate in conjunction with two needles to make two complete and independent lock-stitch seams that must, under all conditions. be perfectly parallel.

The Singer oscillating shuttle always maintains correct tension of the under thread; it is the most effective device existing for perfectly forming the loop of a lock-stitch when running at high speed.

Machine No. 18-5 has drop-feed at left of needle and a roller-presser; No. 18-6 is precisely similar excepting that it is provided with wheel-feed. These machines are especially adapted for VAMPING SHOEs, for which purpose they are extensively used; they can be furnished in any width of gauge between needles, from 1/32 to 1/8 of an inch.

The long-beak shuttles operate so that no slack thread is drawn through the needle-eyes when in the leather or below it, thus permitting use of smaller needles to a given size of thread than is otherwise possible. These are the only left-hand cylinder machines, making a lock-stitch, that sew two exactly parallel rows at one operation, thereby doubling the production; for speed, strength and perfect uniformity of stitch they are unequaled.

The following text was taken from an ISMACS News article John wrote regarding an ISMACS Auction. The color photo also comes from that article. The rest come from the Singer Model List John put together. ~webmaster

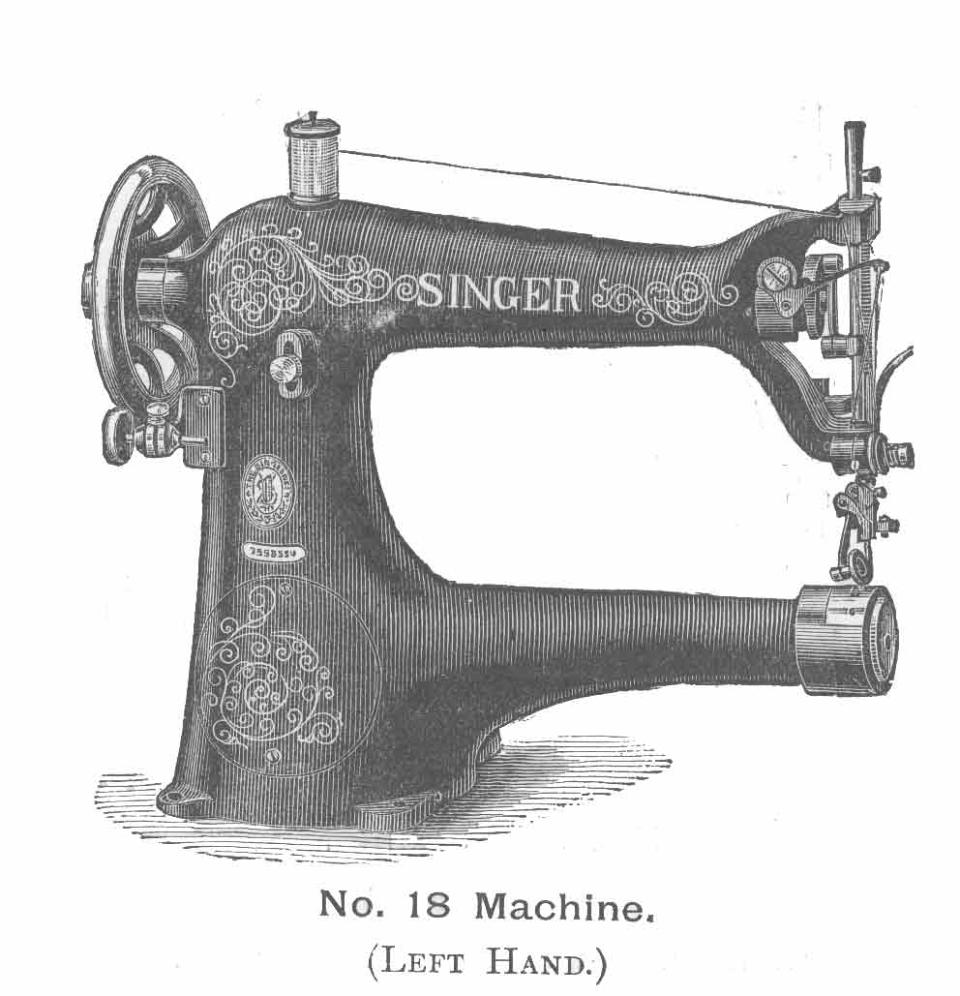

The Model 18

A personal favourite is the Singer 18; not only is it in particularly good order for a venerable and commercially used machine, but it also represents one of Singer's few attempts at catering for lefthanded sewers.

Based on a cylinder arm class 17, the 18 is a complete mirror image, with needle and stitch-forming mechanism on the operator's right. Doubtless it was designed to aid a certain sewing application rather that accommodating southpaws but nonetheless it will be a boon to someone.

Come to think of it, as a right hander, I might even find the back-to-front set-up more intuitive when it doesn't involve hand-cranking.

The Model 18

- Cylinder bed, balance wheel on the left ("LEFT-HANDED").

- Lock stitch, drop feed.

- Optional flat work plate.

- Long beak oscillating shuttle.

- Bed (most models) 16" long, 2 1/2" diam. at end. 10 1/2" space to left of needle.

- Knee or foot lifter.

- Designed for vamping shoes.

- Light and medium weight leather.

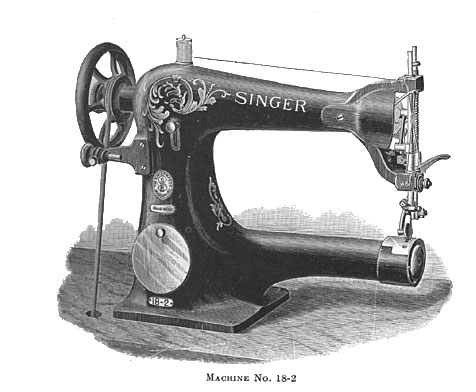

18-2

- One needle.

- Cylinder 2 1/2" x 10 1/2".

- For shoe work.

- Roller presser drop feed.

- Roller feed/drop is to the left of needle.

- Speed 1400.

- Uses Needle: 16x2 (2083)

18-3

- Cylinder 2 1/2" x 10 1/2".

- For shoe work.

- Roller presser and drop feed is to the left of needle.

- Speed 1400.

- Uses Needle: 16x2 (2083)

18-5

- Two needles.

- Cylinder 2 1/2" x 10 1/2".

- For shoe vamping and other work in leather.

- Roller presser drop feed.

- Feed to the left of needle.

- Speed 1400.

- Uses Needle: 16x2 (2083) or 16x22

18-16

- Two needles; maximum 1/4" pitch.

- Cylinder 2 1/2" x 5 1/2". (5" shorter than Nos. 18-1 to 18-9)

- For shoe vamping and other work in leather.

- Feed to the left of needle.

- Speed 1500.

- Uses Needle: 16x2 (2083) or 16x22

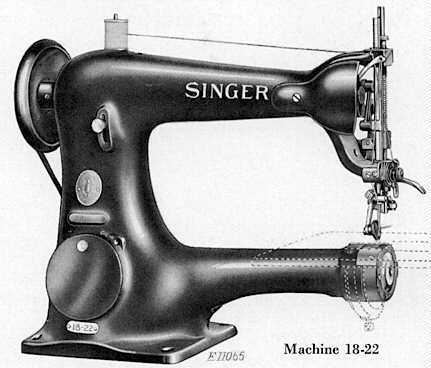

18-22

- For shoe vamping and leather work.

- Maximum stitch length: 6 1/2 to the inch.

- Feed to the left of needle.

- High point shuttle.

- Speed <1800.

- In catalog 9/1954.

See also " The Elusive Left Handed Sewing Machine ".