Class 16.

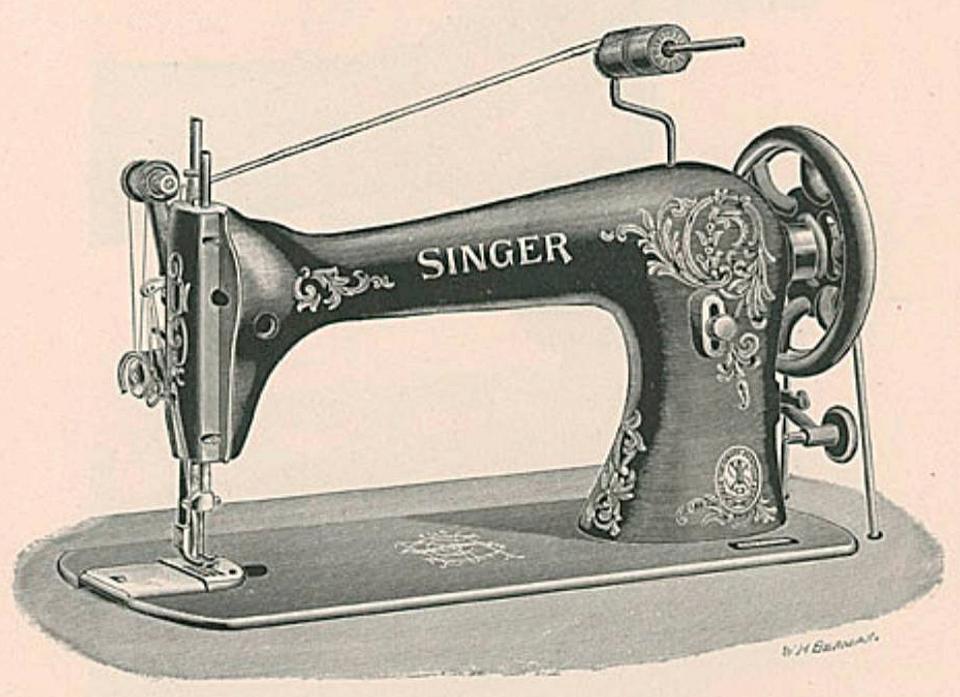

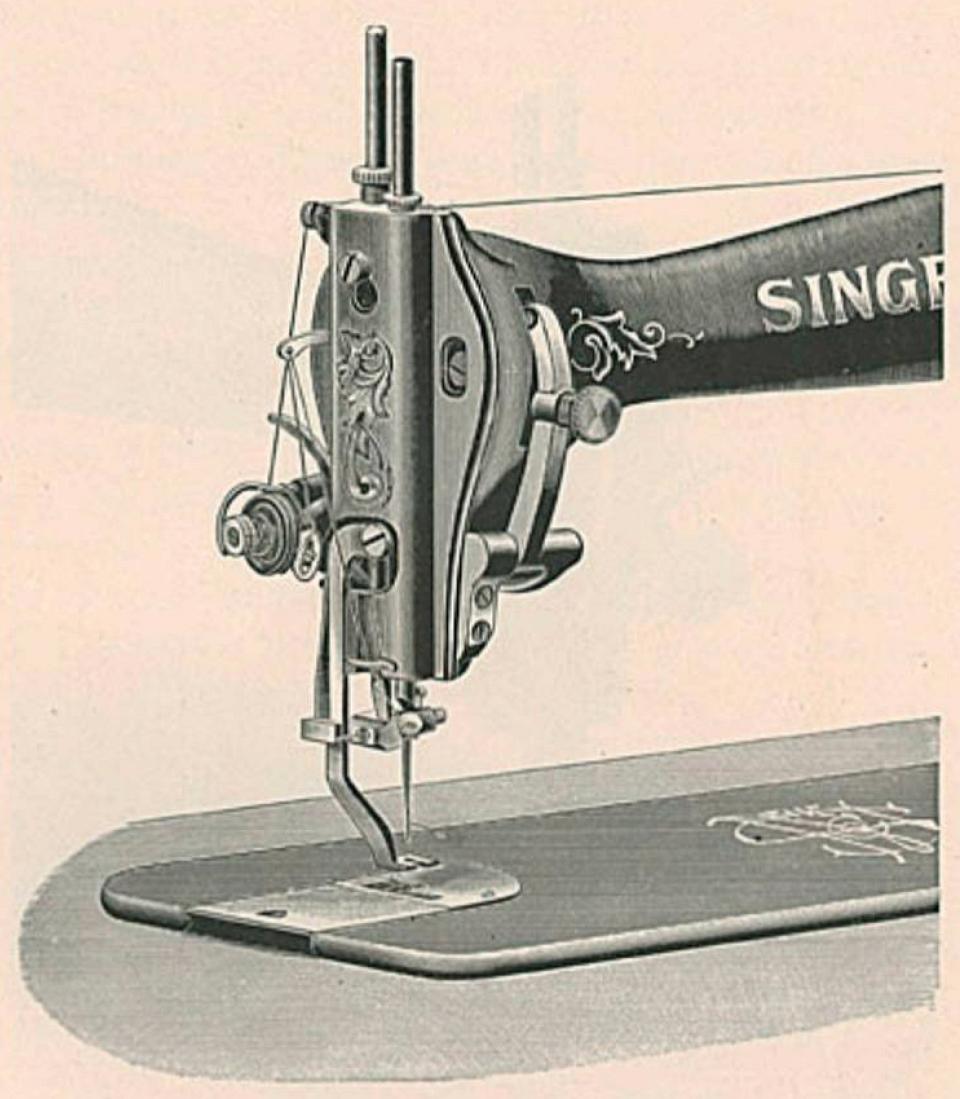

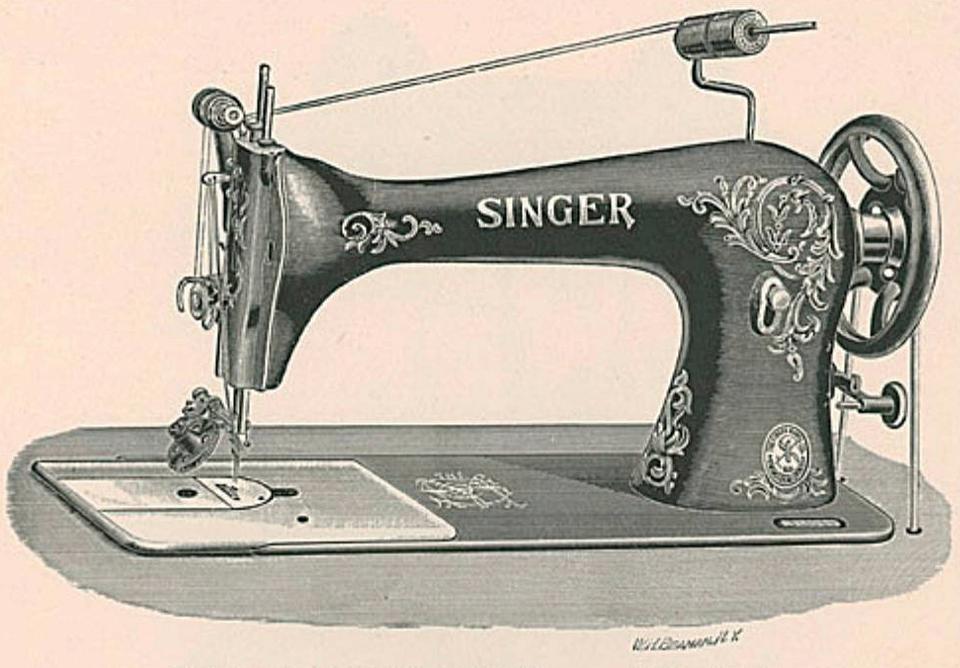

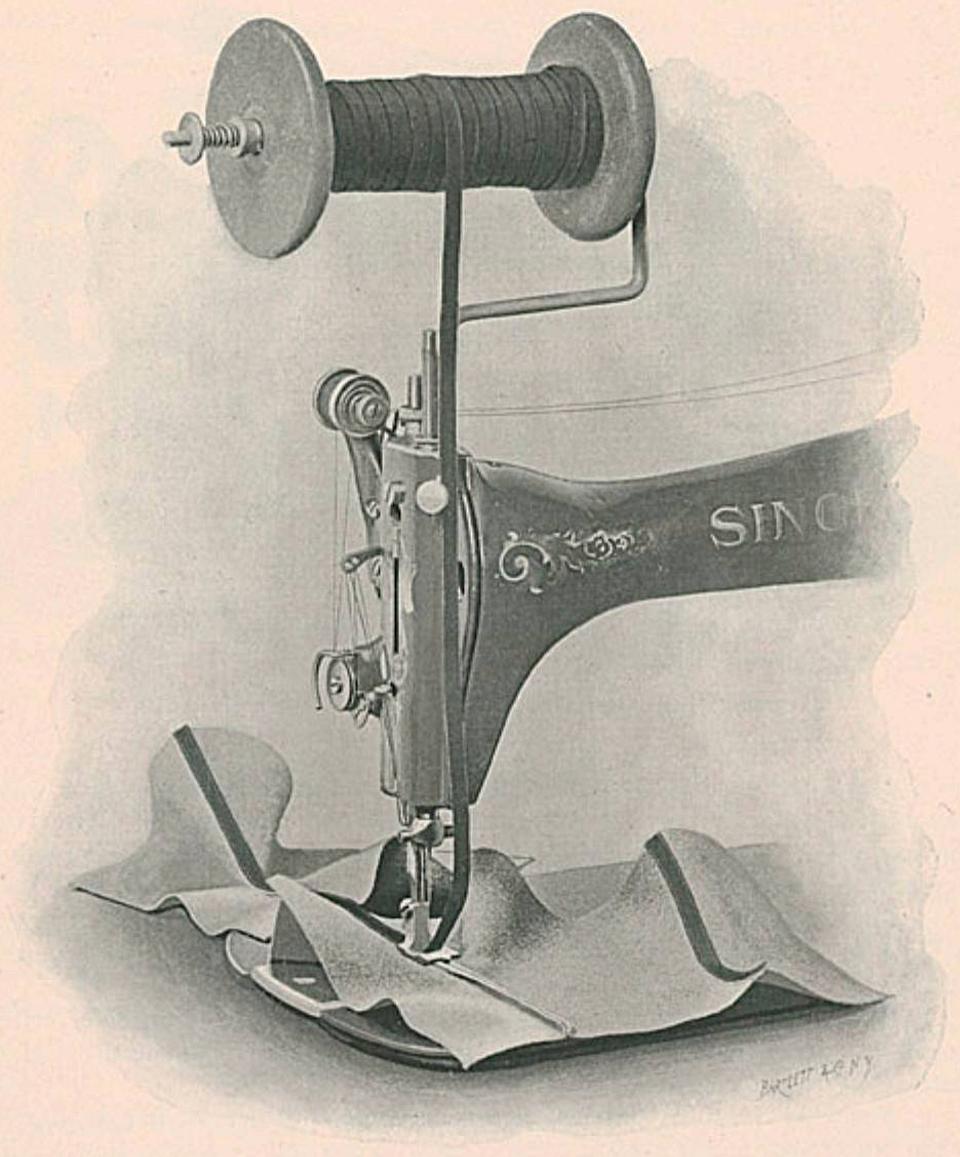

MACHINE No. 16-98

OSCILLATING SHUTTLE. CENTRAL BOBBIN. HIGH LIFT. FOR CARPET MITRES.

Manuals

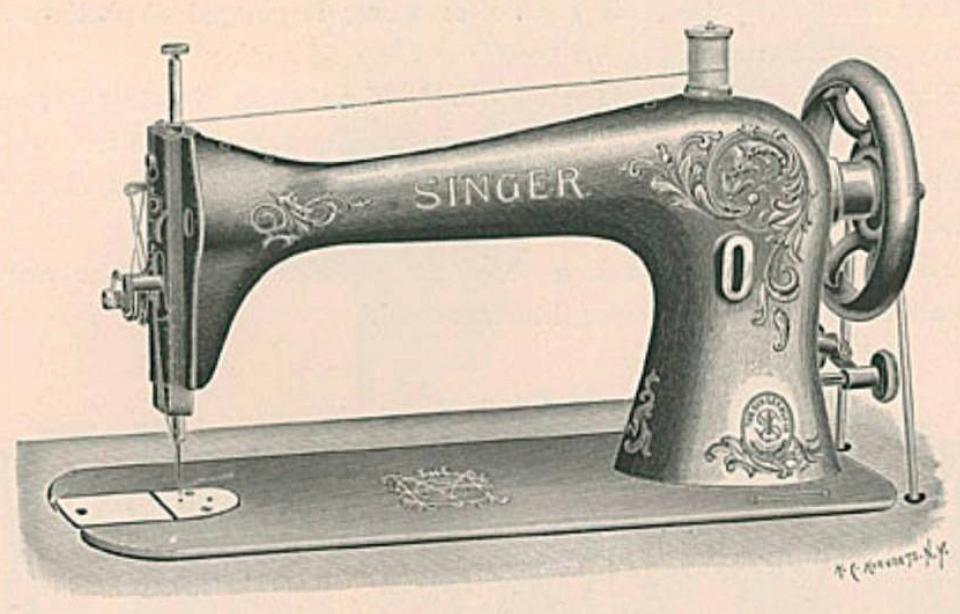

CLASS 16 comprises manufacturing machines of the type formerly known as. "I. M.," having the oscillating shuttle, "I. M. C. B.," having oscillating shuttle and central bobbin, and "I. M.," two needles and two shuttles. The following descriptions of single needle machines in this class only comprise those having the Central bobbin.

The machines of Class 16 are adapted to a great range of work, both in textiles, leather and paper, the number used for manufacturing purposes largely exceeding the aggregate number of all other makes.

Their simple and efficient mechanism enables them to attain the greatest production; the superior workmanship and material used in their construction secure the longest term of high efficiency with the least cost for repairs.

These machines are light running and can be operated either by foot or mechanical power at a high rate of speed. The shape and construction of the bed and arm secure great strength and stability; the bed is 19 inches long on the table, the clear space on bed from needle to base of arm is 10 1/2 inches.

The shuttle is made from one solid piece of steel, hardened and polished; its simple and regular oscillating motion requires the least power and is the most efficient and economical for high-speed lock-stitch sewing-machines. The Central bobbin has capacity for 100 yards of No. 60 cotton, and its delivery of under thread to the material is perfect.

The machines are fitted with a device for lifting the presser-foot by means of a lever under the table; this lever is actuated at will by pressure of the knee, thus leaving the operator's hands free. A tension-release acts automatically when the presser-foot is lifted, thus facilitating the removal of the work.

Various forms of feed, throat-plate and presser are made for the respective varieties of machines in this class, as best adapted to the particular work for which they are required, also hemmers, binders, folders, etc., for special purposes.

In ordering machines to be specially fitted, it is desirable that samples of the material to be used, also specimens of the finished work, be furnished; every machine is operated at the factory and practically tested as to its performance of the duty proposed, before it is sent out.

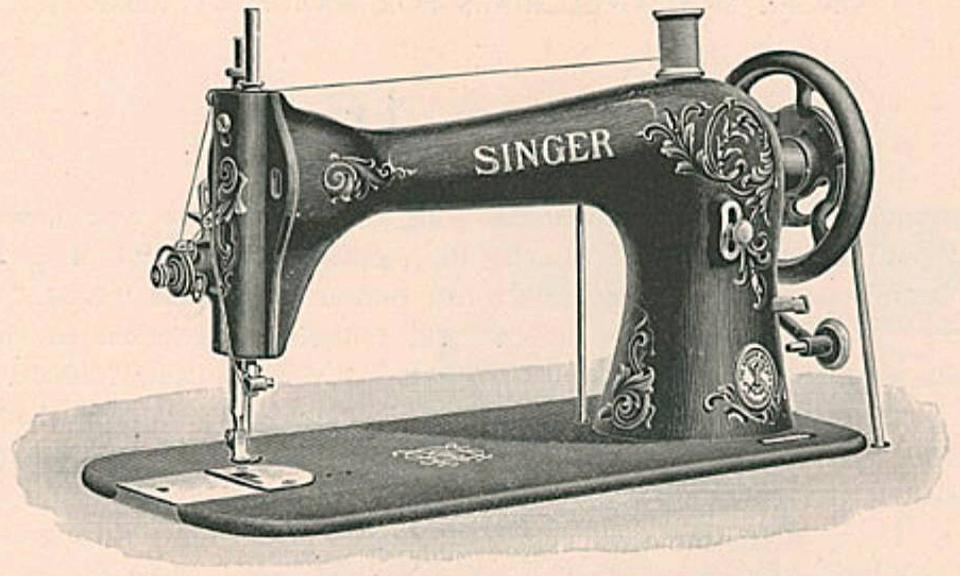

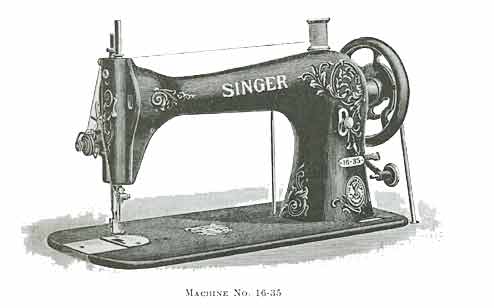

MACHINE No. 16-35

OSCILLATING SHUTTLE. CENTRAL BOBBIN.

Machine No. 16-35 has drop-feed and a plain yielding presser for stitching cloth.

It is extensively used in the manufacture of Men's Clothing, in Custom 'Tailoring, the manufacture of Bicycle Suits, Pants, Overalls, Mackintoshes and other rubber garments, Ladies' Wrappers and Tea Gowns, Cloaks, Suits, Waists, Skirts and Muslin Underwear, Bed Quilts, Comfortables, Horse Blankets, etc. Special feeds, pressers and throat-plates are furnished for work on Shirts, Collars and Cuffs, Corsets, 'Tents, etc., these being more specifically enumerated and illustrated in the complete list of parts pertaining to all the machines of this class.

Machine No. 16-80 corresponds to the preceding description, excepting that its feed-movement is reversible, thus enabling the doubling of the seam at the ends or at any other point, or of making a distinet row of stitching, feeding the material towards the operator.

Machine No. 16-36 has drop feed and both a roller-presser and a plain presser that are interchangeable on the same presser-bar; and its feed-dog and throat-plate are fitted for stitching leather. It is used for edge-stitching and closing Shoes, stitching Gloves, Leather Belts, Razor Strops, Carriage Trimming, Light Harness work, etc.

Machine No. 16-71 also has drop-feed for leather, but is provided with cam on needle-bar.

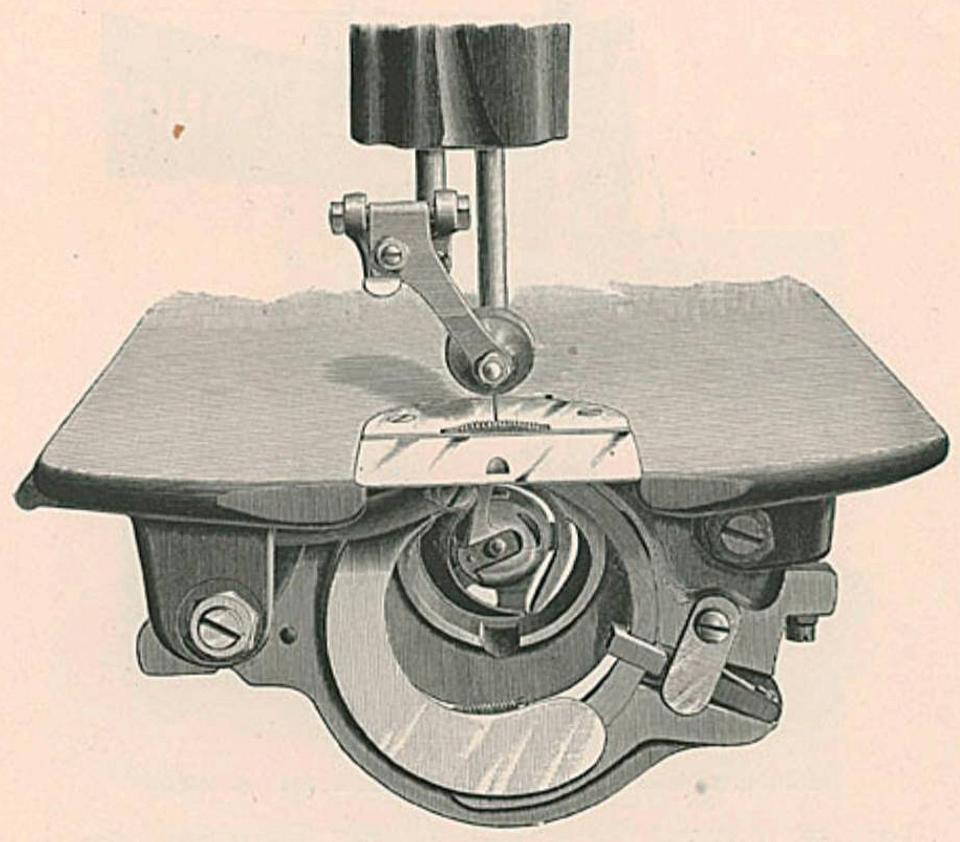

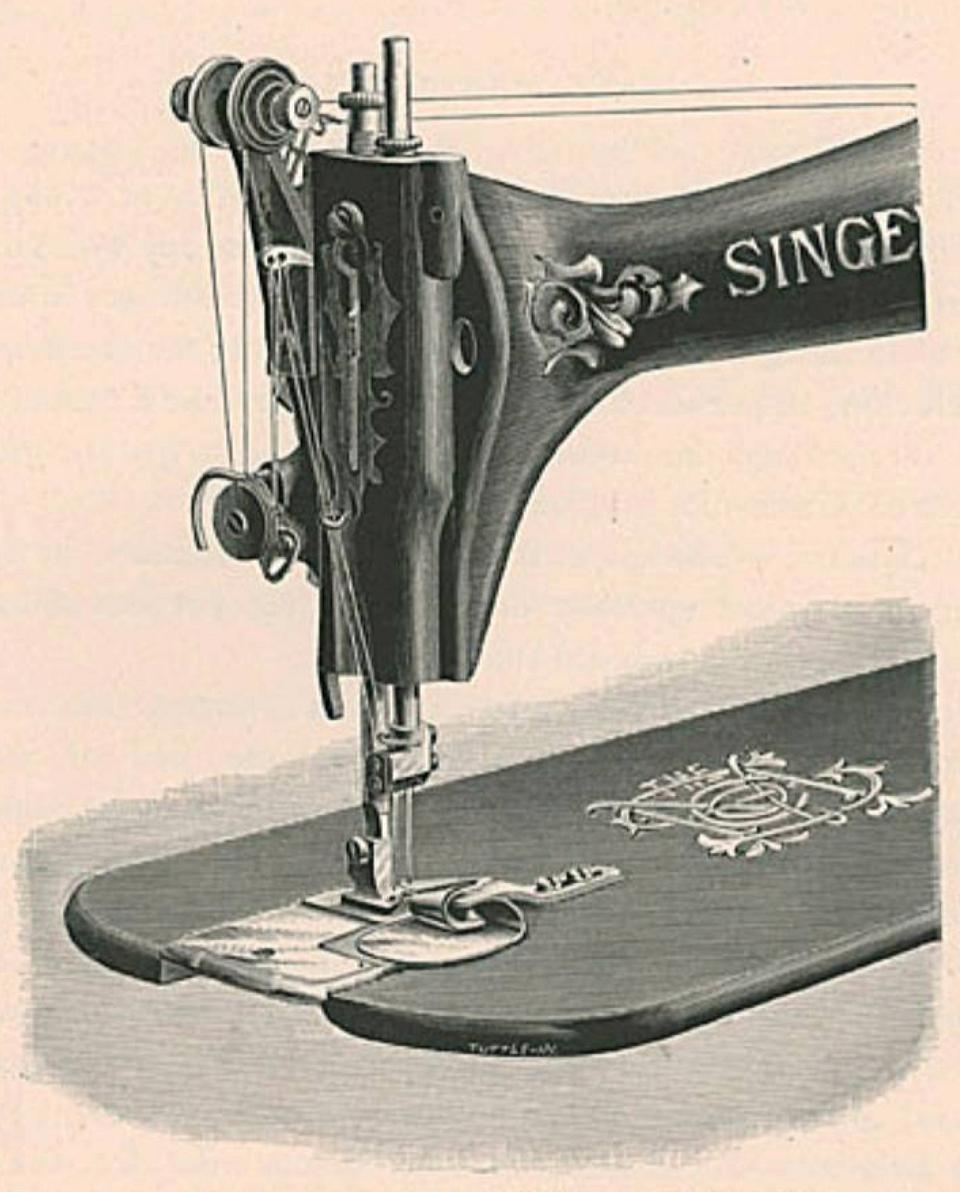

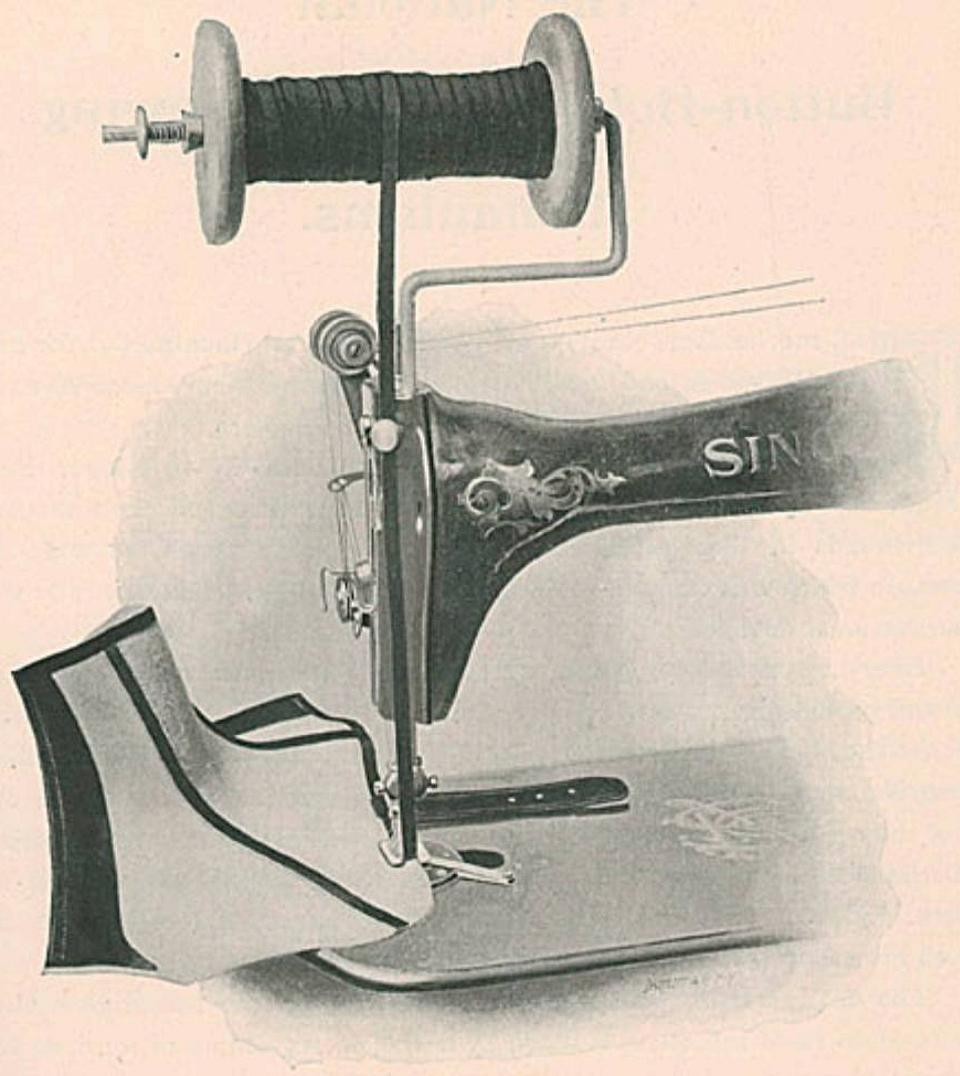

MACHINE No. 16-37

SHOWING ROLLER-PRESSER, WHEEL-FEED AND OSCILLATING SHUTTLE PARTS.

The Wheel-Feed is principally used in connection with a roller-presser for stitching around curves in scolloped work, etc., on leather. This feed-movement, which secures a constant pressure of the material against the feed, is sometimes preferred to the four-motioned drop-feed, for this class of work. The serrated feed-wheel is revolved by means of a friction and clutch device that is positive in its action and has a motion that is in exact relation to the stitch-forming mechanism.

Machines No. 16-37 and No. 16-72 have wheel-feed for leather stitching and are used in Shoe manufacture for vamping and closing, machine No. 16-92 having cam on needle-bar.

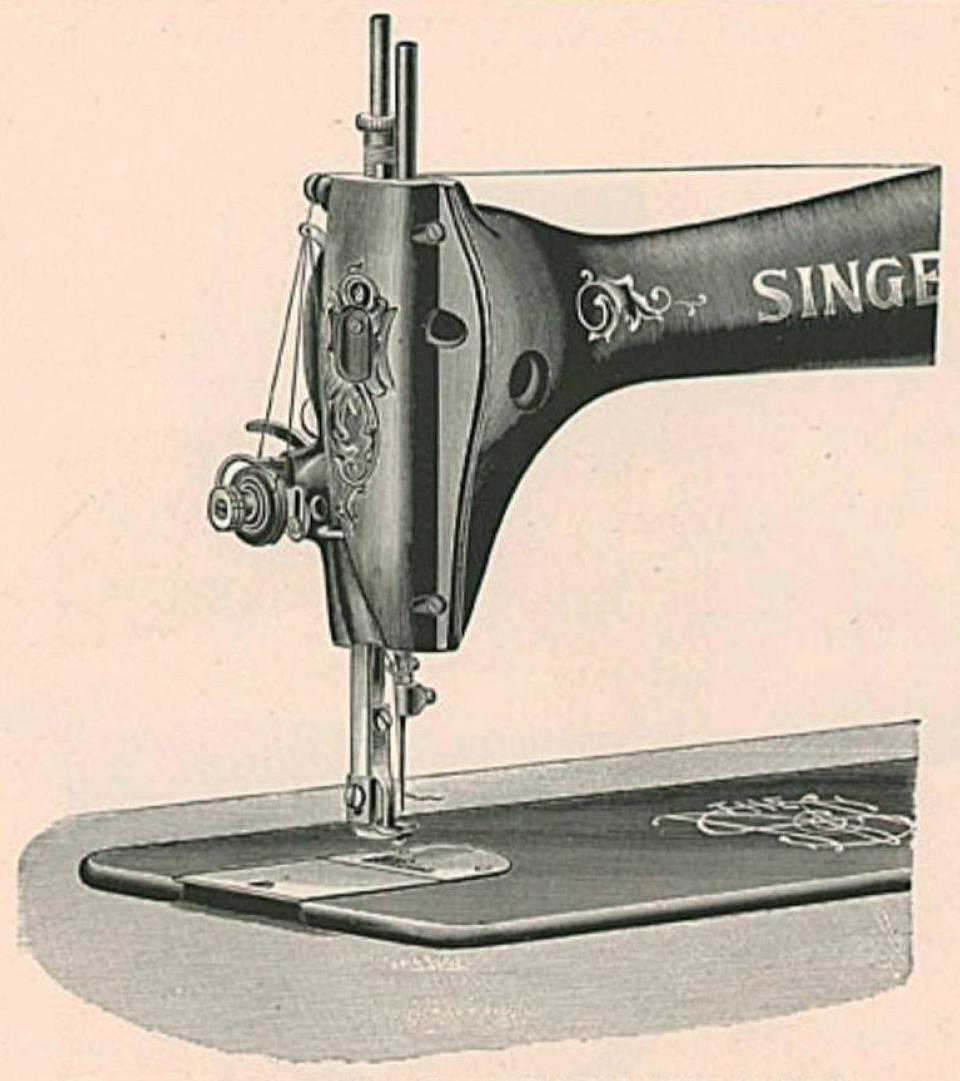

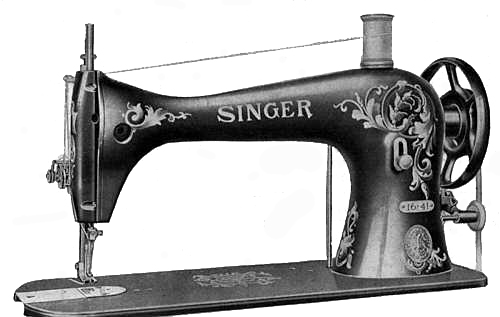

MACHINE No. 16-41

SHOWING ALTERNATING PRESSERS

There are three varieties of Class 16 having Alternating Pressers, viz: Machines No. 16-41, No. 16-82, and No. 16-84. The Alternating Presser comprises two pressers acting separately and alternately; the first moves forward with the feed and is then lifted and returned to its position; the other holds the material down while the first rises and until it descends upon the fabric, but is raised while the material is carried by the feed. Each presser while resting upon the work, forms a fulcrum upon which the other is raised, consequently the height of their movement always corresponds to the thickness of the fabric, thus allowing free passage of material which varies in thickness, and securing perfect formation of the stitch.

By the use of this device, two or more pieces of material are moved with perfect uniformity so that their ends are even at the completion of the stitching. Machine No. 16-41 is extensively used for binding Awnings and similar scolloped work, binding the edges of Flannels, Hats, Mattress-ticks, School- bags. etc.

Special binding attachments can be furnished, orders for which should be accompanied by samples of the binding and of the material to be bound.

Machine No. 16-82 has upper and lower feed and an alternating presser; it is illustrated and described on page 119.

Machine No. 16-84 has 2 needles and? shuttles and alternating pressers: it is illustrated and described on page 120.

MACHINE 16-82

UPPER AND LOWER FEED. Alternating Presser.

Machine No. 16-82, illustrated above, has both upper and lower feed, work- ing in conjunction, and a presser that firmly holds the fabric to the bed during the formation of the stitch; the presser is raised with the needle so as to permit free movement of the material by the simultaneous action of the upper and lower feed-mechanism working alternately with the presser. This alternate action secures the most positive and accurate movement of two or more plies of fabric, preventing all puckering, freely passing any unevenness of thickness and carrying all the plies uniformly so that they are even at the end of the seam. It is especially useful in binding Corsets, as it will stitch the binding around curved edges, attaching it very smoothly and uniformly. It is also used for binding blankets and for stitching the double waistbands for boys' pants; these uses partly indicate the wide range of its capacity.

MACHINE No. 16-84

2 NEEDLES AND 2 SHUTTLES.

Alternating Presser

Machine No. 16-84 has the same form of Alternating Presser as that used on Machine No. 16-41, previously described, but differs in having two needles and two shuttles for making two parallel rows of stitching at once.It is exten ively used for sewing bunting in the manufacture of Flags, where the fabric is soft and spongy and it is essential that the seams be of great strength. For this and similar work this machine is highly efficient.

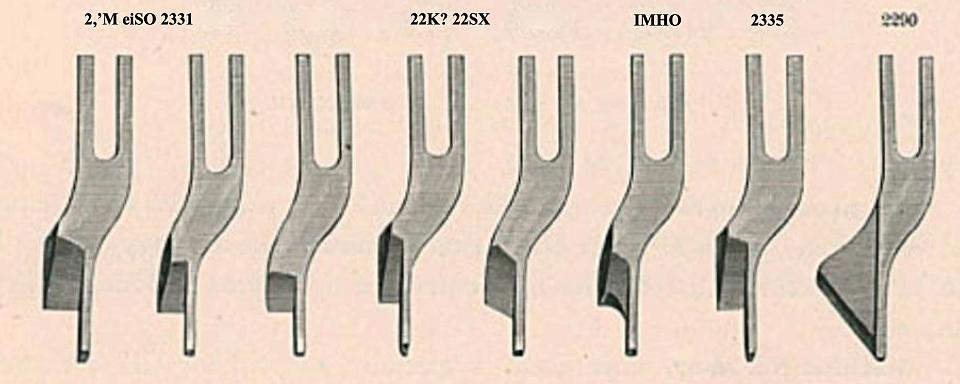

MACHINE No. 16-42

SHOWING VIBRATING PRESSER.

By the use of our Vibrating Presser, illustrated above, a uniformly strong and even feed is seeured in stitching fabrics having rough, uneven or adhesive surfaces or with soft goods liable to pucker.

There are two varieties of Class 16 that are provided with this form of presser, viz: Machine No. 16-42, having drop-feed for cloth or leather, and Machine No. 16-43, having wheel-feed for leather.

These machines are especially adapted for light harness manufacture, for attaching rubber binding to matting, stitching glazed or enameled paper, for binding cap visors, hats, etc.

An adjustable attachment is provided for binding hats (No. 144 A. & A.), by means of which braid is antomatically folded over the edge of the object to be bound, immediately in front of the needle-action.

For binding Cap Visors another attachment is used (No. 191 A. & A.).

Samples of the binding and of the material to be bound should accompany all orders for binding attachments.

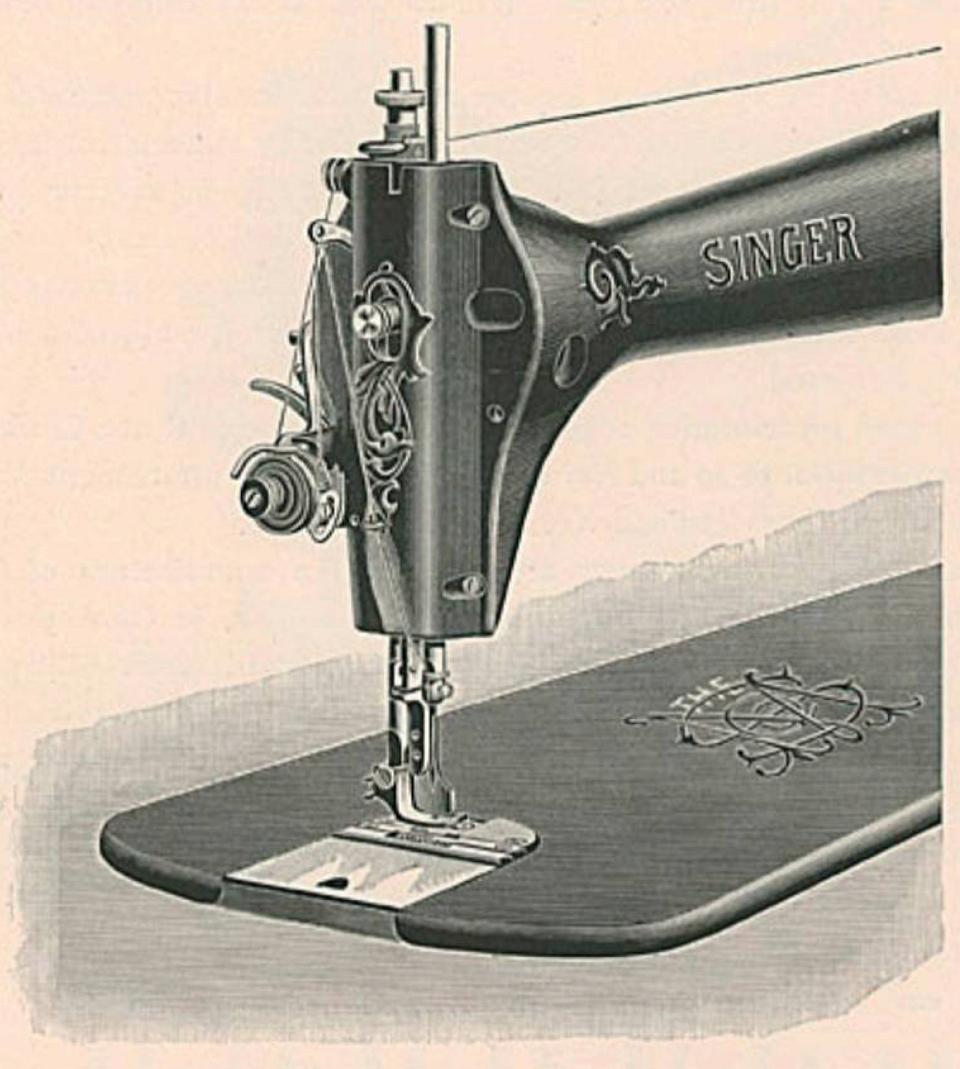

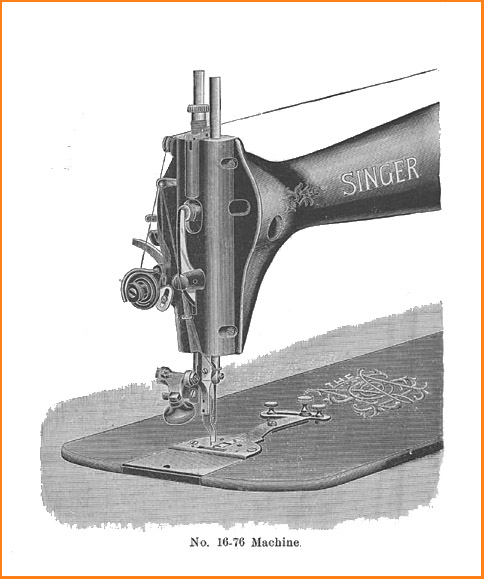

MACHINE No. 16-76

FOR LEATHER

Showing Adjustable Trimming Attachment.

There are six varieties in Class 16 that are provided with an attachment for trimming the edge of the fabric as it is being sewn. They are provided with a bar which receives vertical reciprocating motion from the top driving shaft. The lower end of the bar carries a cutting-knife having an elongation that passes through an opening in the throat-plate on a line directly back of the needle; a spring slide holds this elongation against the cutting bar, thus steadying and keeping the knife-edge in exactly uniform distance from the line of stitch.

Machine No. 16-76, illustrated above, has an attachment fastened to bed of machine by which the throat-plate is moved so that the distance from the line of stitch to the trimmed edge of fabric can be instantly adjusted to any width desired, not exceeding 1/8 inch.

The shape and motion of the knife are such as to cause a clean eut of the edge of the fabric as it is being sewn; it will cut on curved or straight lines exactly parallel to the line of stitch, thus being peculiarly adapted for trimming scolloped as well as straight edges. When not in use the knife can be thrown up, out of the way.

The adjusting attachment is especially useful for manufacturers of Ladies Shoes, when it is required that the silk or cloth facing material at the tops shall be trimmed at one distance and the leather button-flap at another, because the change of gauge can be instantly made.

Machine No. 16-38, for cloth, has a trimming attachment that is not adjustable; the knife makes a broadside-cut that is set either 1/16 or 3/32, of an inch from the needle, as ordered.

It is used for trimming edges in the manufacture of Coats, Cloaks, etc.

Machines No. 16-39 and No. 16-40 have trimming attachment for leather, No. 16-39 having drop-feed and No. 16-40 a wheel-feed.

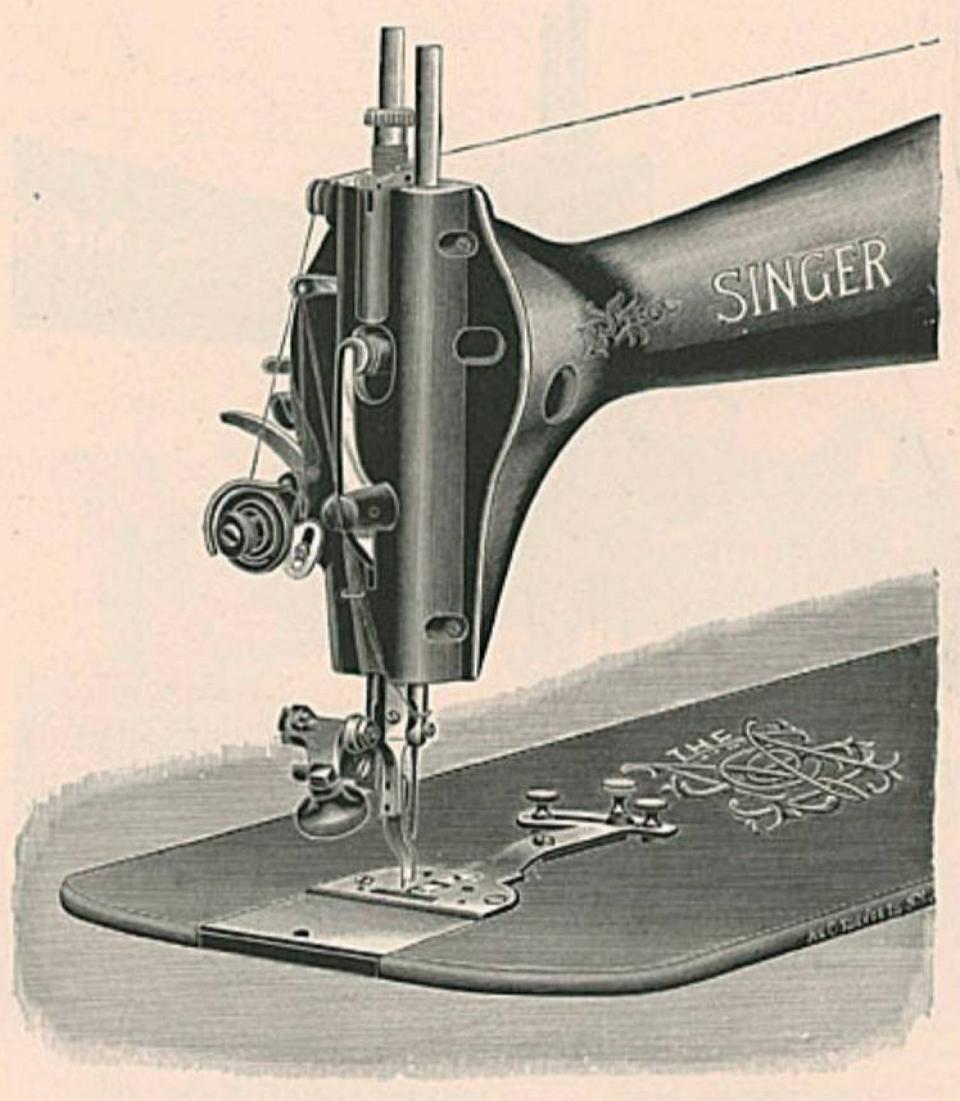

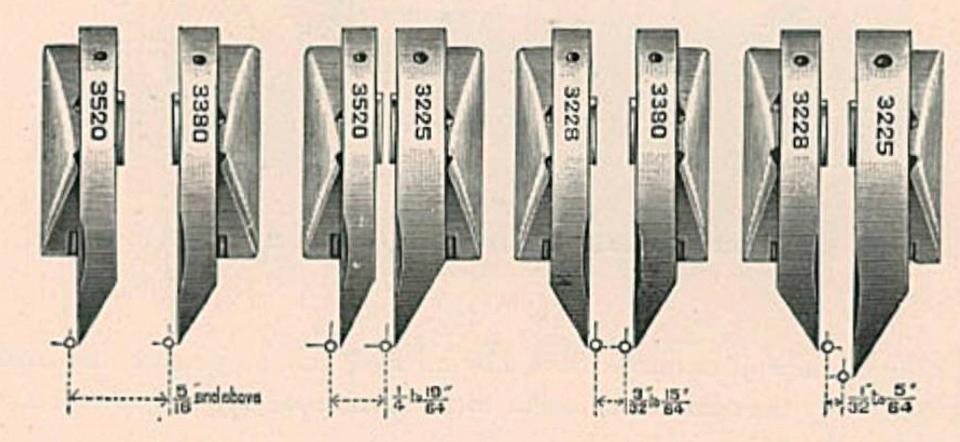

The machines for leather are used in the manufacture of Women's, Misses' and Children's Button Boots, Bicycle Tool Cases, in Glove manufacture, for covering the handles of Traveling Bags, and for all forms of light leather work when it is desirable to use a trimming attachment. Various forms of knives are used, as best adapted to the work to be performed; they can be set to cut either 5/128 or 3/64 of an inch from the needle, as ordered. The knives are shown at full size in the following illustration:

Knife No. 2285 makes a broadside-cut; Knives No. 2286 and No. 2287 make end and side cut; No. 2288 cuts only at end but makes a shearing cut: No. 2289 has concave edge and makes end and side cut; No. 2290 makes a broad, diagonal cut; No. 2334 makes end cut only; No. 2335 is very thin gauge and makes end and side cut.

MACHINE No. 16-86

FOR CLOTH

Machine No. 16-86 has outside feed-bar and is provided with an attachment that trims from 3/32 inch to 1/4 inch from seam in either light or heavy cloth. It is used in the manufacture of Men's, Women's, and Children's Clothing, Bicycle Suits, etc.

Machine No. 16-87, wheel-feed, is specially adapted for Glove manufacture, and has trimmer and yielding presser arranged for most effective work On this class of goods.

MACHINE NO. 16-83

FOR MENDING LACE CURTAINS.

The machine illustrated above has no feed and no presser, the curtain being moved by the operator so as to form stitches of any length and in any direction, as desired.

It is highly efficient for the purpose of mending Lace Curtains, as it enables the formation of a stitch which can be made to closely imitate the lace fabric.

TWO-NEEDLE AND TWO-SHUTTLE MACHINES.

There are five varieties of machines in Class 16 having two needles and two oscillating shuttles for making two rows of lock-stitching at once, that are extensively used in the manufacture of Shoes, Slippers, Overgaiters, Bicycle Tires, Corsets, Corset Waists and Covers, Dress Stays, Shirts and Muslin Underwear, Suspenders and Garters, Collars and Cuffs, Ladies' Cloaks and Jackets, Macintoshes, Jean Pants, Overalls, Coats, Vests, and Clothing generally.

The distance between the rows of stitching is gauged as follows on the respective machines:

No. 16-14 and No. 16-45 from 1/32 to 5/64 of an inch; No. 16-46 from 3/32 to 15/64 of an inch; No. 16-47 from 1/4 to 19/64 of an inch, and No. 16-48 from 5/16 to 1 1/2 inch, the exact distance between the needles being fixed on each of the machines as it may be ordered, within the limits specified.

The relative position and style of the shuttles used for the respective gauges are shown in the following illustration.

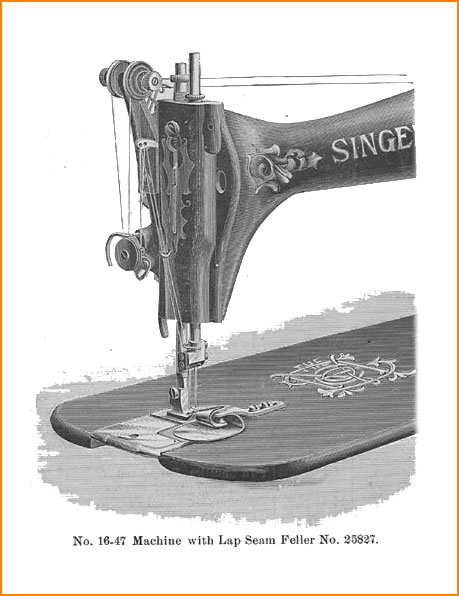

MACHINE No. 16-47

WITH LAP-SEAM FELLER.

The above illustration shows the method of using attachment No. 289 for lap-seam felling on the two-needle and the two-shuttle machines of Class 16.

The attachment for the bed and the special presser-foot are made to order, from 3/32 to 3/8 inch gauge, as best adapted to the fabric to be stitched.

This attachment is extensively used in the manufacture of Corsets, Corset Waists and Covers, Men's, Women's and Children's Clothing, etc.

The following description comprises some of the principal classes of work on cloth upon which the two-needle machines of Class 16 are successfully employed.

CORSET MANUFACTURE.

STRIP STITcHING. A special foot (Parts No. 3958 or 3965) is furnished for guiding, and a tape reel for holding a folded strip of any width desired, both edges of strip being stitched at one operation. A special foot is also furnished for turning and folding both edges of strip as it is fed to the needles.

For stitching upper and lower strip at the same time a special throat-plate is provided for guiding the lower strip; the upper strips are guided by the various forms of presser-foot previously referred to.

BONE CORDING. The spaces for the bones are obtained by the use of a strip-guiding presser-foot specially designed for the purpose and grooved, as ordered, for special widths between the bones.

STITCHING BONE-STRIPS AND INSERTING AT ONE OPREATION. A steel arm is provided which is firmly screwed to the bed of machine and has holes at the end through which the bamboo or bone is guided into the proper spaces between the needles as the strip is being stitched; it may be arranged for any gauge desired.

LAP-SEAM FELLING. Attachments are provided (No. 289 A. & A.) which make a very strong and flat seam; they are furnished in three sizes adapted to the thickness of the fabric, as light, medium and heavy. The attachment is firmly fastened to the bed, but can be readily removed.

LACE BINDING. For binding tops of corsets with lace, the machine is provided with reel for holding the lace; the presser-foot is arranged to so guide the material as to keep the rows of stitching at a uniform distance from the edge of the lace.

STAVING SEAMS. The machine is provided with strip-carrying foot which opens and presses the seam as the stay is being stitched on.

CORDING. These machines can be used for top cording, using attach- ment No. 259 A. & A., which shows the cord only on the upper side of goods, or for top and bottom cording, using attachment No. 267 A. & A., which shows cord equally on both sides. A cord-guiding attachment is provided (No. 210 A. & A.) for top and bottom cording. Special parts can be made as ordered for six to fourteen cords to the inch.

CORSET WAISTS AND CORSET COVERS.

The two-shuttle machines of Class 16 are adapted to all uses in the making of Corset Waists and Covers when two parallel rows of stitchings are desired, such as cording, lap-seam felling, putting on embroidered strip, etc.

MEN'S, WOMEN'S AND CHILDREN'S CLOTHING.

EDGE STITCHING. -Two parallel rows of any desired gauge can be stitched around a garment at a uniform distance from the edge.

COVERING SEAMS WITH FOLDED STRIP. The machine is furnished with special folder-foot to carry and turn in the edges of cut cloth for Children's Waists, Jackets, etc.

JOINING SEAMS WITH LAP-SEAN FELLER. For Ladies' Cloaks, Children's Jackets, Jean Pants, Overalls, Shooting Jackets, Leggins, etc. Feed parts are furnished as best adapted to the various classes of work.

SHIRTS AND MUSLIN UNDERWEAR.

JOINING SHIRT SLEEV TO BODY WITH LAP SEAM. The machine is furnished with a lap-seam feller (No. 289 A. & A.) for turning the edge of the material;this simple device is easily operated and makes a strong and flat joining. The needles are gauged as ordered, usually from ‡ to & inch.

SEAMING-UP SHIRT SLEEVES AND CLOSING THE BODY. The attachment is the same as described for Joining Sleeve and makes a lap-seam. The needles are usually gauged from # to finch, but can be set as ordered.

INSERTING SHIRT BOSOMS. The machine is furnished with a folder-foot which folds a cut strip, either straight or bias, and delivers it to the needles while the bosom is being stitched to the body of a shirt. The strip is placed on a reel located on the top of the overhanging arm. The needles are usually gauged from 3/16 to 1/4 inch, as ordered.

REINFORCING SHIRT FRONTS. This operation consists in stitching a strip of cut material from the arm-pit to the bosom and is performed by the use of the same appliances as described for inserting bosoms.

PIECING SHIRT SLEAVES. Machine No. 16-14 with needles gauged 1/16 inch apart, is fitted with special presser-foot and feller similar to No. 217 A. & A. for the purpose of piecing shirt sleeves and for similar work requiring fine felling.

BOSOM PLAITING (Either Box or Side Plaiting). -Special attachments are furnished which automatically make a perfect box or side plait. In making a box plait the bosom material is laid, face upward, on the throat-plate in front of the needles and is folded by the attachment into the proper form and guided under the needles so that both sides of the plait are stitched simultaneously. It is extensively used in the manufacture of Shirt Waists and Neglige Shirts. The side-plaiting attachment folds and stitches two plaits at once and can be used on any ordinary material.

The plaiting attachments are connected to the presser-bar so that the knee lift operates both.

SEWING ON EMBROIDERED STRIP. The machine is furnished with strip- reel and a tubed foot which guides the strip directly to the needles, thus making it possible to stitch very closely to the edge of the strip while making short curves and still retain the same uniformity of distance as in straight work.

COLLARS AND CUFFS.

For Collar and Cuff manufacture the machines are furnished with special forms of drop-feed, presser-foot and throat-plate which are used with a special combination-guide enabling the stitching of two parallel rows very close to, and at a uniform distance from the edge.The distance between the rows of stitching can be gauged as ordered.

FOR JOINING EDGES OF BOLTING CLOTH.

An attachment is furnished for lapping the edges of the material and, if desired, for stitching on an upper strip or stay at the same time. The folders are made in pairs, right and left, and are easily removed from the machine. By their use the thinnest, as well as the heaviest cloth, can be rapidly stitched with. out puckering.

LADIES' DRESS SHIELDS.

Machine No. 16-18 can be gauged from 5/16-inch upwards and fitted with a special presser-foot for stitching ladies' dress shields.

SUSPENDERS.

Machine No. 16-48 is fitted with a special attachment for folding both upper and under strips in the manufacture of satin and silk Suspenders. The needles are gauged 14 inches apart, the edges of the white backing material being folded over so as to make a contrasting finish to the face material; the face material, interlining, and backing are all folded and both edges stitched at one operation.

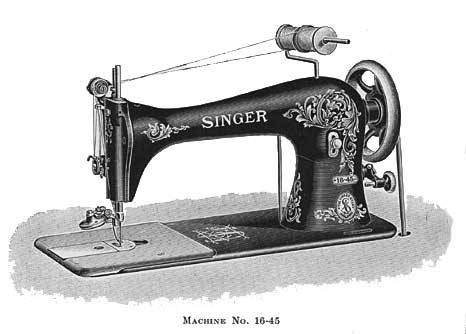

MACHINE No. 16-45

FOR LEATHER.

Machine No. 16-45, illustrated above, is fitted with wheel-feed and roller-presser for leather; it is extensively used in Shoe manufacture for narrow two. row vamping. Machine No. 16-41, drop-feed and roller-presser, is also used for the same purpose.

Machines No. 16-46, No. 16-47 and No. 16-48 have drop-feed, and are used in Shoe manufacture for wide two-row vamping, for stitching on tips, putting on back stays, and stitching inside stays.

The roller-presser used for narrow two-row vamping is provided with a needle-guard, attached to presser-foot, which keeps the insideneedle and the material in proper position.

For wide two-row vamping an auxiliary yielding presser-foot is attached to the presser-bar and is used in connection with the roller-presser, thus holding the material flat to the feed so that perfectly true and parallel stitching is secured.

For stitching on Shoe Tips a special form of presser-foot is provided for the purpose of guiding and keeping the lines of stitching an equal distance from the edge of the tip.

For putting on Outside Stays another form of presser-foot is used to hold and guide the stay, and a convenient form of tape-reel is provided.

For stitching Inside Stays the machines are fitted with a special stay-guide and an upper tape-reel.

Either of these operations may be performed on the same machine by simply changing the feed, the presser-foot and the throat-plate; the distance between the rows of stitching will be uniform in each operation, the gauge being fixed in the construction of the machine.

MACHINE No. 16-46

STAYING CLOTH OVERGAITERS.

The above illustration shows the process of staying the front seam on Cloth Overgaiters by the use of Machine No. 16-46.

The tape is delivered through an opening in the presser foot directly in front of the needles. The presser-foot has a tongue for opening the back of the seam and guiding the material; acting on the opposite side is a thin spring-guide in the throat-plate, which works in conjunction with the top-guide and presser so that the material is perfectly guided without aid from the operator. By the use of these special devices a very smooth and flat seam is made that requires no pressing and the most rapid production is secured.

MACHINE No. 16-46

TAPING CLOTH OVERGAITERS.

The above illustration shows the process of taping the outer edge of Cloth Overgaiters on Machine No. 16-46 with needles gauged 3/16 of an inch apart. A special presser-foot is arranged so that the tape is kept at a uniform distance from the edge of the cloth. The throat-plate is furnished with a yielding spring-guide which sinks into a recess so that the strap passes over it readily.

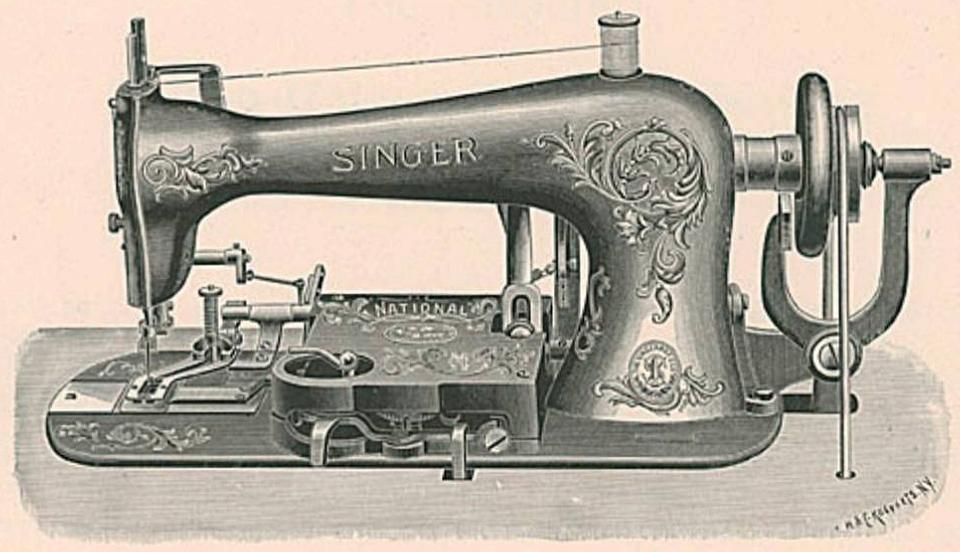

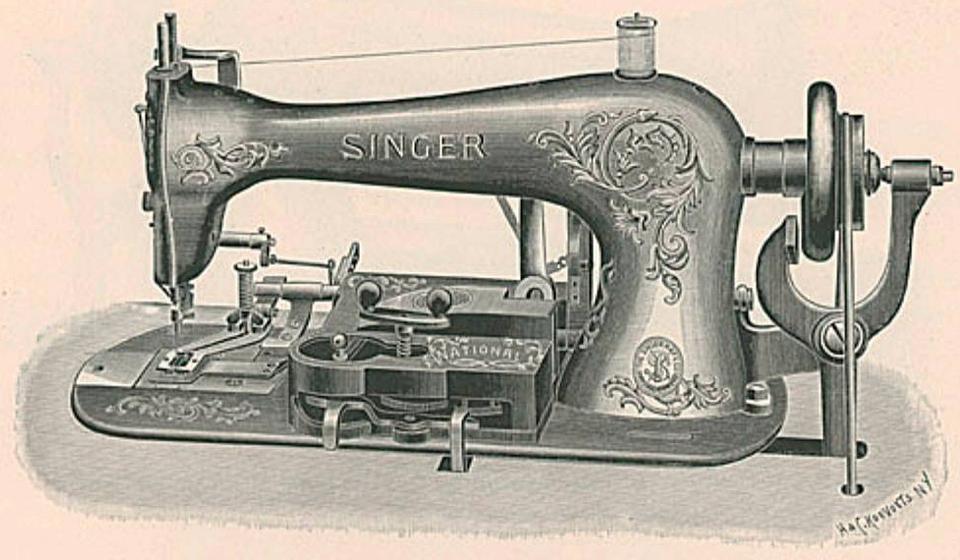

The National Button-Hole and Button-Sewing Mechanisms.

THE mechanisms constructed by The National Machine Co., for making button-holes and for sewing on buttons, are in extensive and successful practical operation throughout the world.

These devices are attached exclusively to Singer Sewing-Machines of Class 16; their action is entirely automate and their mechanical construction is the best attainable. Their range of work is the widest; any material in which it is desirable to stitch button-holes can be successfully worked by the National devices.

Every appliance suggested by experience for improving the quality of work and promoting the convenience of the operator, has been so combined as to secure the highest excellence and greatest quantity of output. Their absolute automatism insures perfect uniformity of work, and but ordinary skill on the part of the operator is necessary. Any one competent to run a sewing-machine can become reasonably expert in the use of these devices after a few hours' practice. All changes of adjustment necessary to suit them to different varieties of work are easily and quickly made without requiring change of parts.

The change from "whip" to "purl" stitch, on the machines numbered from 16-51 to 10-54 inclusive, is made by a simple regulation of tensions and by the application to the shuttle-carrier of a thread-slacking device that accompanies each machine. No thread-slacker is required for machines No. 16-55 and No. 16-56, as the change is effected by simply regulating the tensions.

These machines are in extensive use by manufacturers of White Shirts, Percale, Flannel and other Negligé Shirts, Collars and Cuffs, Ladies' Waists, Suits and Wraps, Children's and Infants' wear, Corset Waists, Waistbands, Men's Clothing, Overalls, Jumpers, Pants, Knee-pants, Cardigan Jackets, Muslin and Knit Underwear, Blouses, Coats, Rubber and Mackintosh Garments, Silk Mitts, etc.

Automatic Cutter: The National Automatic Cutting device is absolutely unique and is not used in any other form of button-hole machine.

It secures perfect accuracy of work, permitting narrowest cutting space and obtaining clean edges of cut.

Its use effects a clear saving of from 20 to 33 per cent in the cost of making button-holes. The cutting is done by the machine while stitching, so that the operation is performed without any loss of time whatever.

Operatives always prefer this machine because it produces the best work with the least labor. The quantity of its product is only limited by the expertness of the operator in handling the work. The time required for stitching by power and cutting a medium-sized button-hole of good quality is only from 15 to 20 seconds. These machines, as regularly fitted, will make button holes of any desired length, from 1/8 inch to 1 1/4 inches, of finished opening. By special fitting, the length of this opening can be increased to 1 3/8 inches.

Four Cutting blades of different sizes accompany each machine.

MACHINE No. 16-54

FOR STRAIGHT BUTTON-HOLES.

The National Button hole machine was the first that was successfully used for working straight button holes, by the manufacturing trade.

Since its introduction its history has been a record of uninterrupted and increasing success. In the wide field of work that it covers, comprising every class of garment in which a straight button-hole is used, it is the best for its purpose. ep Machine No. 16-51 is for foot power. It is provided, in common with the three varieties following, with Automatic Cutter, Tension Release and Bobbin Winder.

Machine No. 16-52 is for operation by mechanical power and has Auto- matic Stop-motion.

Machine No. 16-53 can be operated by either foot or mechanical power. It has Foot presser-lifter but is not furnished with Automatic Stop-motion.

Machine No. 16-54, illustrated above, is for operation by mechanical power. It has Automatic Stop-motion and Foot presser-lifter. All the machines of this series are distinguished for rapidity of production and aceuracy of work.

MACHINE No. 16-56

FOR INTERLOCKED SQUARE-BAR BUTTON-HOLES.

The demand for "fine hand work" led to the introduction of this machine. It is equally adjustable and nearly as rapid as Machine No. 16-54 and is fitted with the same automatie improvements for cutting, stopping, releasing tension, etc.

Its work is of the highest class in either purl or whip stitch; in uniformity and durability it is superior to hand work.

The peculiar feature of the button-hole made by this machine consists of the interlocked square bar that is automatically made at each end of the buttonhole. This form of bar gives the most handsome finish and the greatest strength to the button-hole and secures the "fine hand-made" appearance so desirable on first class goods.

Machine No. 16-55 is for operation by foot power; it has no stop-motion and a hand presser-lift is substituted for the foot-lift.

In changing Machine No. 16-55 and No. 16-56 from "purl" to "whip" stitch, no thread-slacker is required, as the change can be effectively made by simply regulating the tension.

MACHINE No. 16-69

FOR SEWING ON 2 AND 4 HOLE AND BAR BUTTONS

This machine has had the test of practical work in garment manufactories throughout the world during a number of years, and has become established as the most successful for its purpose.

It is used for sewing Two-hole, Four-hole, or Bar buttons onto any description of garment, obtaining absolutely stronger and neater work than can be produced by any other means.

It is extensively used by manufacturers of Men's Pants, Knee-pants, Blouses, Jumpers, Overalls, Shirts, Knit and Muslin Underwear, Ladies' Suits, Cloaks, Shirt Waists, Wrappers, Cardigan Jackets, Bicycle Suits, Bathing Suits, Children's and Infants' Garments, Rubber and Mackintosh Garments, etc.

It sews with the greatest rapidity, the stitch being uniformly well secured and neatly finished. The peculiarity of its stitch in sewing the button all round greatly increases the strength and beauty of the work, as compared with any other method.

The action of this device is entirely automatic; its mechanism is simple and its construction the best attainable.

It is instantly adjustable for varying sizes and styles of buttons and is fitted to make 8, 12, 16, 20, 24, 28, 32, 36 or 40 stitches as desired; by special fitting any number of stitches can be made, divisible by 4.

Since the number of stitches is an automatic feature of the machine, the operator cannot slight the work by reducing the number, and each button is uniformly well secured.

The machines for sewing on buttons are fitted with a Universal Clamp in any one of three sizes, as ordered, viz:

Small, for attaching buttons up to 16 line.

Medium, for attaching buttons from 16 to 24 line, inclusive.

Large, for attaching buttons over 24 line.

It will be observed that either one of the clamps has sufficient range of work for any single line of goods.

Machine No. 16-70 corresponds to No. 16-69 excepting in the clamp, which opens and closes automatically as it is raised or depressed.

In actual use by manufacturers the choice between this and the Universal Clamp is about equally divided.

In ordering these machines it is desirable to state the sizes of the largest and the smallest buttons on which it is to be used, so that the proper clamp may be fitted

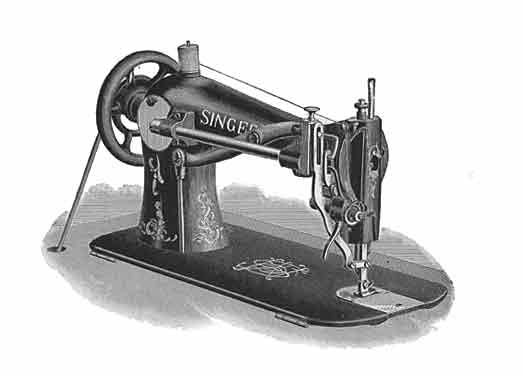

The following is lifted from John Langdon's Comprehensive Model List

'Improved Manufacturing'

|

c.1879- | Industrial | Originally 'fiddle' base. Base (of most models) = 19 1/2" x 8 1/2". "It is larger and stronger than the IF (Improved Family), but light running and with more room under the arm..." Parts were available to convert machine to alternating presser, wheel feed, roller presser etc. Became the Class 16. | |

| 16- (class) | Industrial | Bed 19 inches long, 10 1/4" space at right of needle. Lock stitch. Oscillating shuttle. Generally with knee lifter. For a variety of work of clothing and heavier work in woven fabrics, also in shoe work and many other articles in leather; some varieties fitted with lap seam fellers, folders, binders, corders and other attachments. | - | |

| 16K (class) | 1890 - | Industrial | See class 16-. However, the 1950 catalogue page gives bed size as 18 3/4" long, by 7" wide and 10 1/2" space to the right of needle. | |

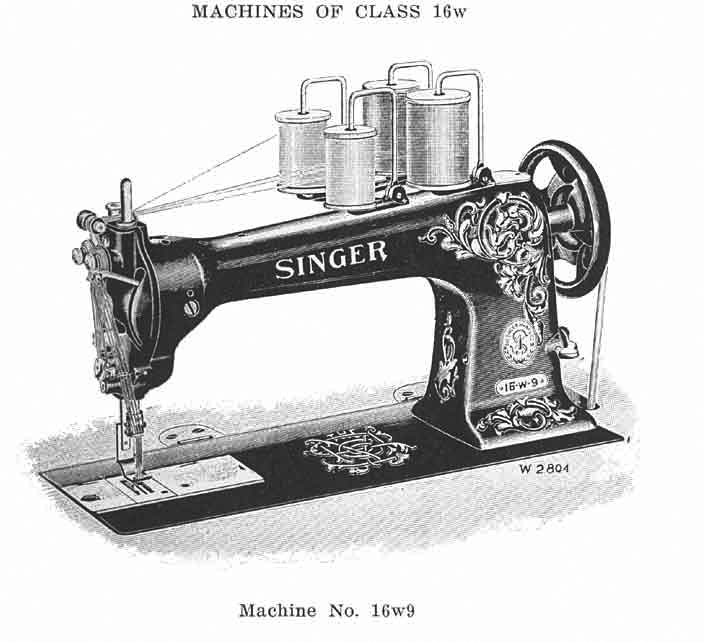

| 16W (class) | Industrial | Rotary motion, lockstitch, transversely located hook. 1200 SPM. Bed 19 1/2" x 8 1/2". For sewing 2, 3, 4, 5, or 6 seams simultaneously. | - | |

| 16K1 | Industrial | Oscillating shuttle; drop feed. For general cloth work. | 16x1 | |

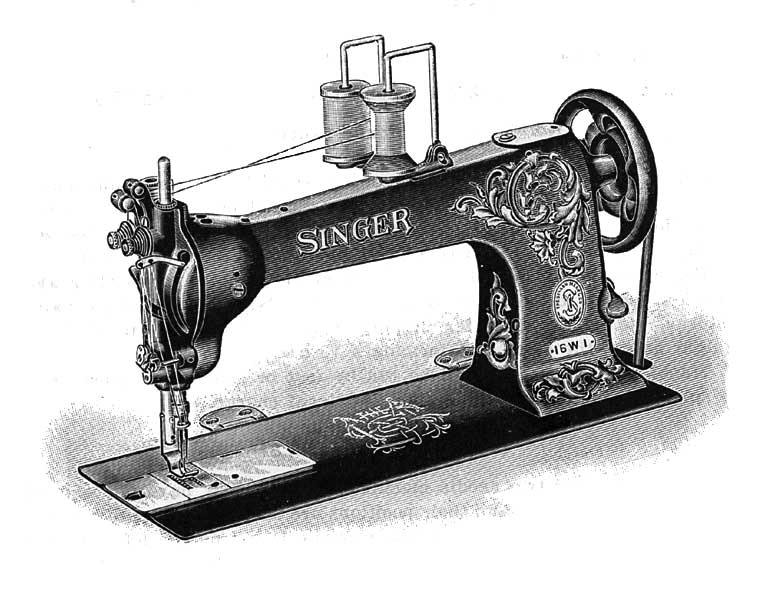

16W1

|

(Cancelled 07/1938) | Industrial | For cording and imitation cording or air tucking. Two needles. Drop feed. Speed 1400. Singer suggested replacement 16W2 (specially fitted). | 131x13 or 131x17 |

| 16W2 | Industrial | For ornamenting gloves. Two needles. Speed 1200. | 131x13 or 131x17 | |

| 16W3 | Industrial | For ornamenting gloves. Three needles. Speed 1000 | 131x13 or 131x17 | |

| 16W5 | Industrial | For ornamenting gloves. Four needles. Speed 1000 | 131x13 or 131x17 | |

| 16K5 | Industrial | Oscillating shuttle; drop feed; vibrating presser. | 16x1 | |

| 16W6 | (Cancelled 07/1938) | Industrial | Singer suggested replacement 16W9 (specially fitted). | |

| 16W7 | (Cancelled 07/1938) | Industrial | Singer suggested replacement 16W2 (specially fitted). | |

| 16W8 | (Cancelled 07/1938) | Industrial | Singer suggested replacement 16W2 (specially fitted). | |

| 16K9 | Industrial | Oscillating shuttle; drop feed. Lifting presser. | 16x1 | |

16W9

|

Industrial | For ornamenting gloves. Four needles. Speed 1000. Drop feed. Supercedes 16W4 and 16WSV10. | 131x27; 131x29 for silk. | |

| 16W10 | (Cancelled 07/1938) | Industrial | Singer suggested replacement 16W9 (specially fitted). | |

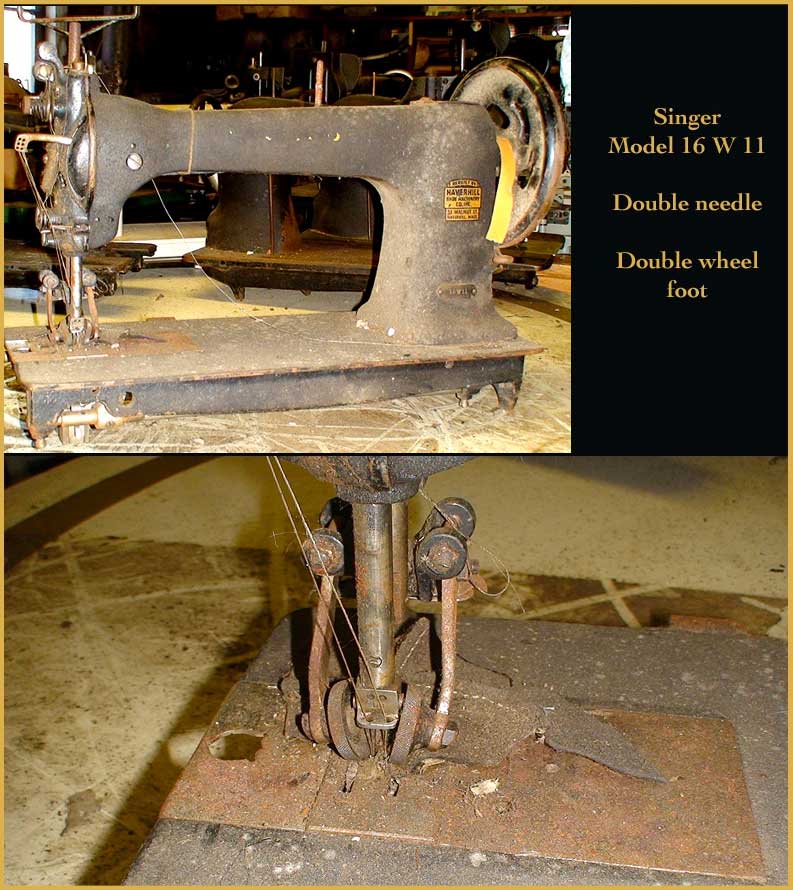

16W11

|

Industrial | (Photos: Mike Anderson) | ||

| 16K13 | Industrial | Oscillating shuttle; wheel feed; vibrating presser. | 16x2 | |

| 16K15 | Industrial | Oscillating shuttle; wheel feed; lifting presser. | 16x2 | |

| 16K23 | Industrial | Oscillating shuttle; drop feed. For leather. | 16x2 | |

| 16K25 | Industrial | Oscillating shuttle, wheel feed, roller presser, for leather. | 16x2 | |

| 16-26 | Industrial | Oscillating shuttle; drop feed; Speed 1500. For cloth. | 16x1 | |

| 16-27 | Industrial | Oscillating shuttle; drop feed; Speed 1500. For leather. | 16x2 | |

| 16K27 | Industrial | Oscillating shuttle; drop feed; for waxed thread. | 16x2 | |

| 16-28 | Industrial | Wheel feed. for leather. Speed 1500. | ||

| 16K28 | Industrial | Oscillating shuttle, wheel feed, roller presser, for waxed thread. 1800 spm Electric or foot power. | 16x2 | |

| 16-29 | Industrial | Drop feed. Trimming attachment. For cloth. Speed 1400. | ||

| 16K29 | Industrial | Oscillating shuttle; drop feed; vibrating presser; 2 speed balance wheel. | 16x1 | |

| 16-30 | Industrial | Drop feed. Trimming attachment. For leather. Speed 1400. | ||

| 16K30 | Industrial | Long beak shuttle, drop feed, vertical trimmer. Wheel feed. 1800 spm For leather. | 16x2 | |

| 16-31 | Industrial | Wheel feed. Trimming attachment. For leather. Speed 1400. | ||

| 16-32 | Industrial | Drop feed. Alternating pressers. Speed 1400. | ||

| 16-33 | Industrial | Drop feed. Vibrating pressers. Speed 1400. | ||

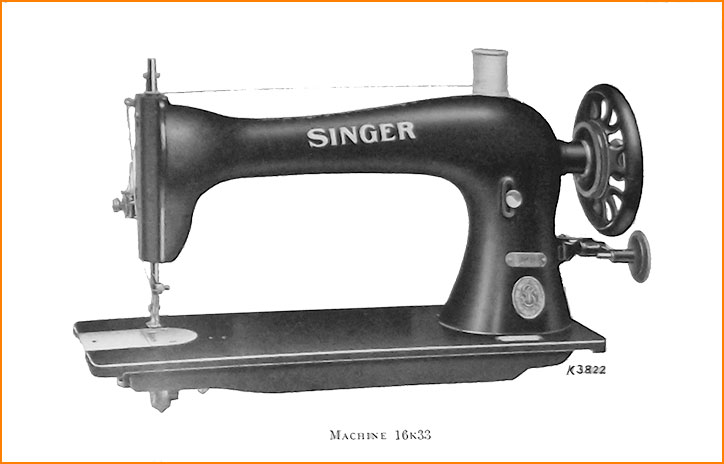

16K33

|

Industrial | CB shuttle, drop feed, for general cloth work (flat bed machine). 1800 spm .For general cloth work. | 16x73 | |

| 16-34 | Industrial | Wheel feed. Vibrating pressers. Speed 1400. | ||

16K34

|

Industrial | |||

16-35

|

Industrial | C.B. Drop feed. Cloth. Speed 1600. | ||

| 16-36 | Industrial | C.B. Drop feed. Cloth. Speed 1600. | ||

16-37

|

Industrial | C.B. Shuttle. Wheel feed. For leather. Speed 1600. | 16x73 | |

| 16K39 | Industrial | C.B. Shuttle. Drop feed; lifting presser. Speed 1200 spm. | 16x73 | |

| 16-40 | Industrial | C.B. Wheel feed. Trimming attachment. For leather. Speed 1400. | ||

16-41

|

Industrial | Oscillating shuttle, alternating pressers, for sewing cloth or light/medium weight leather in binding, clothing, sandals, shoe tongues, rubber coats, mattresses, carpets, lap robes, gun covers, automobile and carriage trimming etc. | ||

| 16K41 | Industrial | Oscillating shuttle, alternating pressers. For sewing cloth or light/medium weight leather; binding, clothing, sandals, shoe tongues, rubber coats, mattresses, carpets, automobile. | ||

| 16-42 | Industrial | C.B. Drop feed; vibrating pressers. Speed 1400. | ||

| 16-43 | Industrial | C.B. Wheel feed; vibrating pressers. Speed 1400. | ||

| 16K43 | Industrial | C.B. Shuttle. Wheel feed; vibrating presser. | 16x74 | |

| 16K44 | Industrial | Two needles, long beak shuttles. 1/32” to 5/64” gauges Drop feed. Speed 1400. For shoe vamping. | ||

16K45

|

Industrial | C.B. Shuttle. Wheel feed; lifting presser. As 16-44 but with wheel feed. Speed 1400 | 16x73 | |

| 16K46 | Industrial | As 16-44 but with wider gauges. Speed 1400. For shoe vamping. | ||

16K47

|

Industrial | |||

| 16K53 | Industrial | C.B. Shuttle. Drop feed. Speed 1500 spm. Roller presser. For leather. | 16x74 | |

| 16K55 | Industrial | C.B. Shuttle. Wheel feed. Roller presser. Speed 1500 spm For leather. | 16x74 | |

| 16-71 | Industrial | C.B. Drop feed; cam on needlebar; for leather. Speed 1400. | 16x74 | |

| 16-72 | Industrial | C.B. wheel feed; cam on needlebar; for leather. Speed 1400. | 16x74 | |

16-76

|

Industrial | C.B. Drop feed; adjustable trimming attachment. Speed 1400. For leather | 16x74 or 16x86 | |

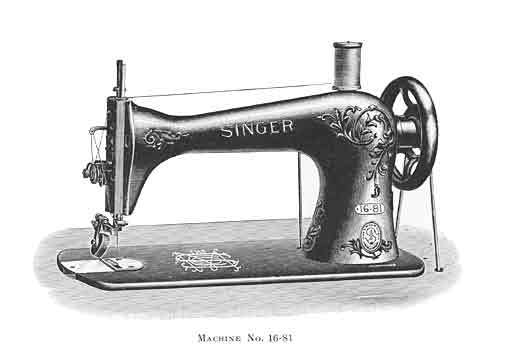

16-81

|

Industrial | Drop feed, roller presser. Bed 19" long. Space at right of needle 10 1/2". For book and pamphlet sewing. Speed 150. | 16x228 | |

| 16-82 | Industrial | C.B. drop feed. 1" stitch. Speed 1400. Upper and lower feeds. Alternating pressers. | 16x73 or 16x74 | |

| 16-83 | Industrial | C.B. NO FEED PARTS. Speed 600. For lace darning. | 16x27 | |

16-84

|

||||

16-88

(reverse)

(reverse)

|

Industrial | Oscillating shuttle. Independent upper and lower feeding mechanisms, for general work in cloth and leather. High lift. | ||

| 16-89 | Industrial | Oscillating shuttle. Drop feed. Reversible. Speed 1500. | ||

| 16-90 | Industrial | C.B. Drop feed. Reversible. Speed 1500. | ||

16K98

/td>

/td>

|

Industrial | C.B. Shuttle. Drop feed; with high lift. For carpet mitres. | 29x3 | |

| 16K100 | Industrial | C.B. Shuttle. Drop feed; with high lift and hinged presser foot. For corduroys and fustians. | 29x3 | |

| 16K104 | Industrial | Single chain stitch, with looper. 2 to 6 stitches to inch. For sack and dye work. | 207x1 or 207x3 | |

| 16K105 | Industrial | Double-chain stitch, with looper mechanism, 2 to 6 stitches to inch. For sack work. | 207x1 or 207x3 | |

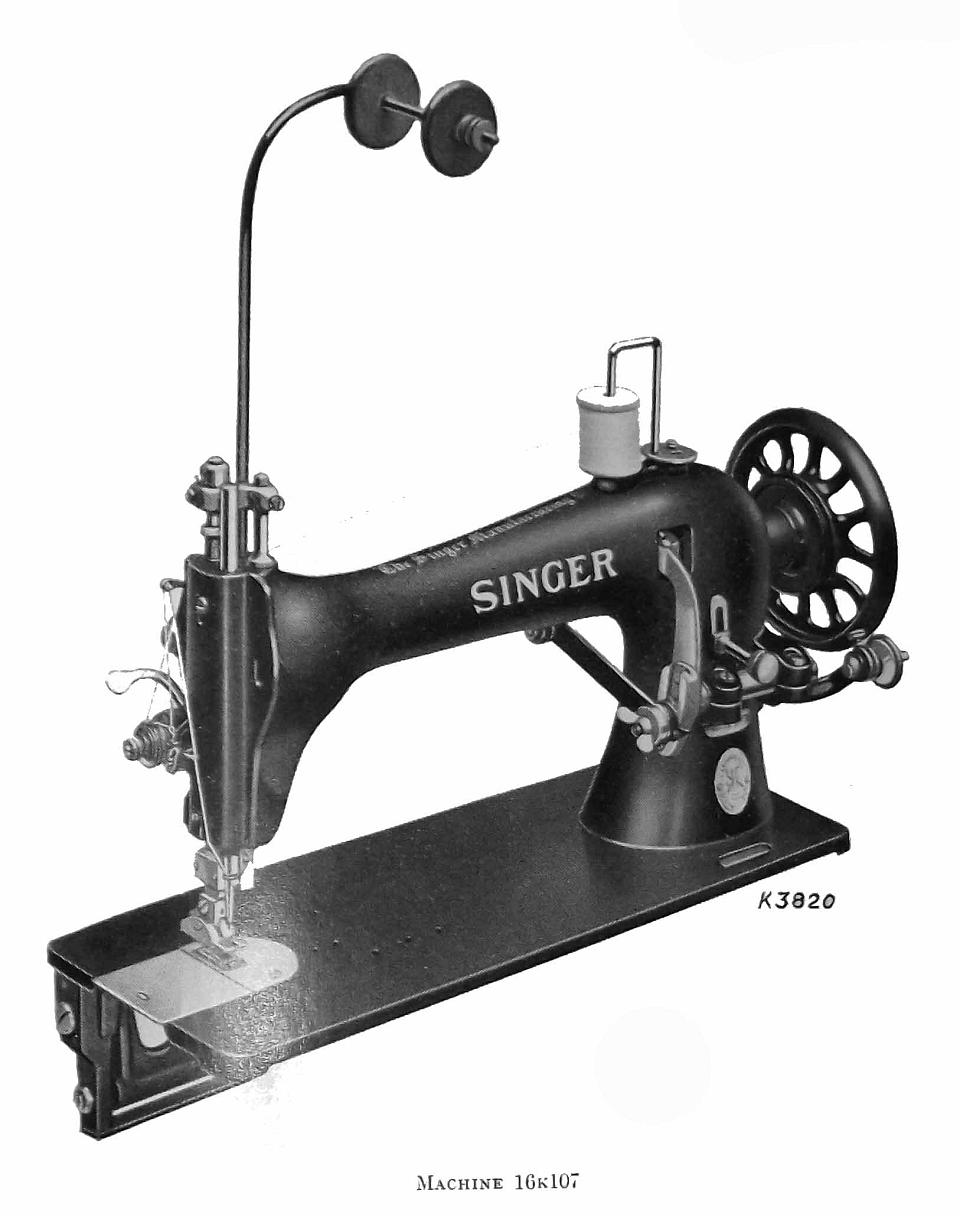

16K107

|

Industrial | Top and bottom feed. Max stitch length 3 to the inch. Cannot be supplied with Balance Wheel Stop Motion (the others can). CB shuttle #125018. Speed 600 spm. High lift for welting, rug binding, etc. Speed 600. | 29x3 | |

| 16K108 | Industrial | C.B. Shuttle. Drop feed. For 1/2" stitching. | 16x73 | |

| 16K110 | Industrial | C.B. Shuttle. Wheel feed. Roller presser. Speed 800 spm. For waxed thread. | 16x74 | |

| 16K111 | Industrial | C.B. Shuttle. Universal feed with feed controlling handle on bottom. For Lettering, scroll tracing, etc. | 16x73 | |

| 16K112 | Industrial | C.B. Shuttle. Drop feed; reversible; with high lift and hinged presser foot. For corduroys and fustians. | 29x3 | |

| 16K113 | Industrial | C.B. Shuttle. Drop feed. Reversible. Speed 1200 spm. For cloth. | 16x73 | |

| 16K114 | Industrial | Oscillating shuttle; drop feed; reversible. For cloth. | 16x1 | |

| 16K115 | Industrial | C.B. Shuttle. Drop feed. Alternating presser. For military clothing. | 29x3 | |

| 16K116 | Industrial | Oscillating high point shuttle; with positive stop motion. "Fanning" for power. For high speeds. | 16x1 | |

| 16K117 | Industrial | C.B. Shuttle. NO FEED. For darning linen, napkins, sheets, table cloths, towels, etc. | 16x27 | |

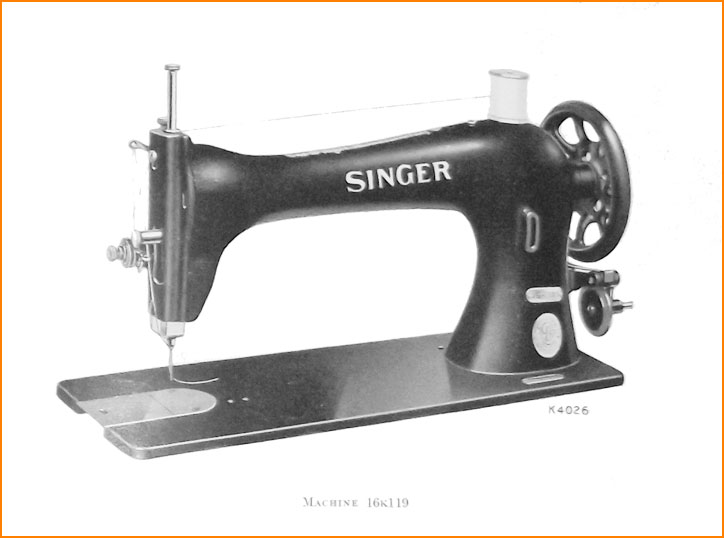

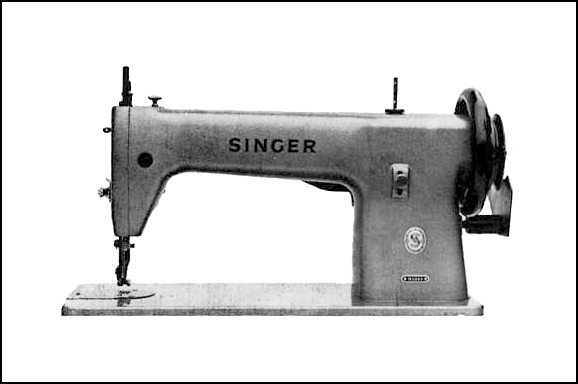

16K119

|

Industrial | C.B. Shuttle. NO FEED. For darning or mending lace curtains. | 16x27 | |

| 16-121 | Industrial | CB shuttle, no feed, clamp stop motion, for darning and embroidery work. | ||

| 16K121 | Industrial | CB shuttle, no feed, clamp stop motion, for darning and embroidery work. | ||

| 16-133 | Industrial | Drop feed, presser foot. For general cloth work. | 16x87 | |

16-137

|

Industrial | |||

| 16-141 | Industrial | Drop feed, alternating presser feet. For sewing cloth or light and medium weight leather; binding clothing, sandals, shoe tongues, rubber coats, mattresses, carpets, etc. | 16x63 or 16x4 (16x198 size 22 for auto work.) | |

16-188

|

Industrial | Upper AND under feeding mechanism, adjustable independently so that upper or under fabric may be fed slower or faster. Drop feed. High lift presser foot, 9/32" clearance. For sewing cloth or light/medium weight leather in the manufacture of waterproof covers, bags, tarpaulins, leather trims, etc. | 16x63 or 16x4 | |

16U288

|

Industrial | Single needle flat bed. Makes lockstitch FST 301. Independent drop feed and presser feet. Speed 1400. 7 stitches per inch. Long arm. For general work in cloth or leather. Also Binding, cording and piping. In 1988, this was the last 16 class machines left in the catalog. | Cat. 3861-01 |