Class 15.

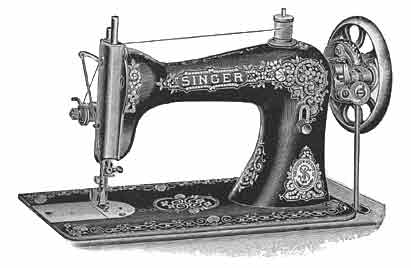

THE machines of Class 15 are especially adapted for making a fine lock- stitch on light fabrics at high speed.

This class comprises machines of the type formerly known as " I. F."having the oscillating shuttle, and "I. F. C. B.," having oscillating shuttle and central bobbin. These machines are compact and light running so that they can be easily operated at a high rate of speed, either by foot or mechanical power.

The Singer Oscillating Shuttle: This shuttle mechanism is the simplest and most effective method extant for making a lock-stitch. There is but one simple conversion of motion - rotating to oscillating - no differential movement nor variable speed. The steadily increasing use of this type of sewing-machines by manufacturers is the best evidence of its practical superiority in combined ease and speed of operation, capacity and durability.

The Central Bobbin: The bobbin does not oscillate with the shuttle but is held stationary. It has capacity for 100 yards of No. 60 cotton and the delivery of its thread to the material is perfect under all conditions.

The Tension Release: This is an automatic device which acts in conjunction with the lever for raising the presser-foot. Whenever this lever is lifted the tension discs are automatically opened and allow free passage of the upper thread. This enables the operator to draw down the thread easily in order to cut it at the end of a seam or to remove the work for any purpose. All danger of withdrawing the upper thread from the needle when starting the machine is entirely obviated and the correct tension is instantly restored when the presser- foot is lowered.

Much time is saved and a distinct increase of product gained by the use of this device.

The Knee Lift: The machines are fitted with a device for instantly lifting the presser-foot at will, by means of knee pressure against a lever hanging beneath the table, thus leaving the operator's hands free and greatly promoting the facility and convenience of operation.

Special Fittings: Various forms of feed, throat-plate and presser are made for the respective varieties of machines, as best adapted to the particular kind of work for which they are intended; they are also fitted with hemmers, binders, folders, etc., for special purposes as ordered.

Every machine is practically tested before leaving the Factory, as to its performance of the work for which it is intended.

In ordering machines to be used for special purposes, it is desired that samples be furnished, of the material to be used and also of the finished work.

The following descriptions only include the varieties of Class 15 that have the Central Bobbin.

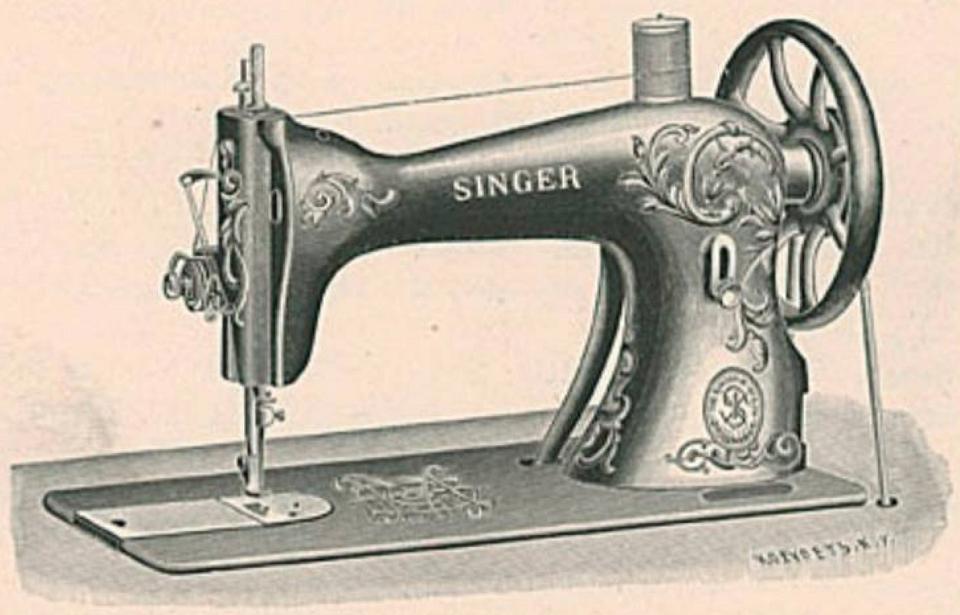

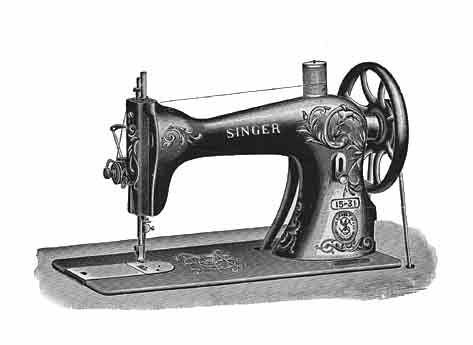

MACHINE No. 15-31

FOR POWER.

The above illustration shows the plain head as furnished for use on power table, for manufacturing purposes.

Machine No. 15-31, is for the general stitching of textiles and has dropfeed and yielding presser.

It is most extensively used in the manufacture of Colored and Outing Shirts, Corsets, Ladies' Shirt-Waists, Silk Waists and Blouses, Ladies' Dresses, Suits, Costumes and Dress-Skirts, Ladies' Wrappers and Tea Gowns, Linen and Muslin Underwear, Children's and Infants' Wear, Bathing Suits, Silk Lamp. Shades, for hemming Handkerchiefs, Suspender Ends, Umbrella Covers, etc.

Machine No. 15-32 has drop-feed and Machine No. 15-33 has wheel-feed, both machines being adapted for fine work on leather in the manufacture of Fine Shoes, Gloves, etc.

Machine No. 15-34 is specially fitted for the manufacture of Collars and Cuffs and Machine No. 15-35 for White Shirts and Linen goods.

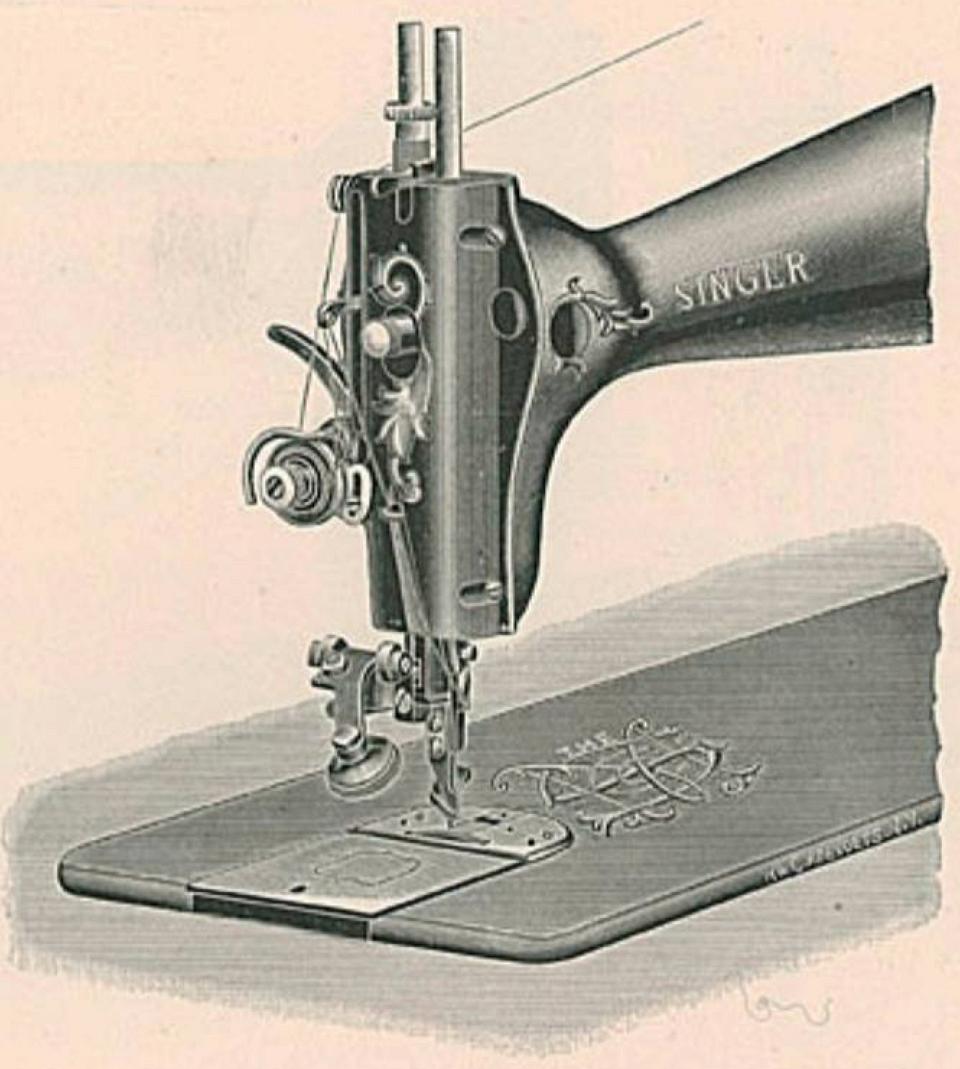

MACHINE No. 15-36

FOR GLOVE WORK.

There are three varieties of machines in Class 15 that are provided with an attachment for trimming the edge of the fabric as it is being stitched; they are described as follows:

Machine No. 15-36, illustrated above, has wheel-feed; it is specially adapted for Glove manufacture and euts a clean, smooth edge on the soft leather used for this work.

Machines No. 15-37, drop-feed, and No. 15-38, wheel-feed, are for general leather work and are used in the manufacture of Shoes, Leather Belts, covering Rings and Buckles with leather, Leather Boxes, Novelties, etc.

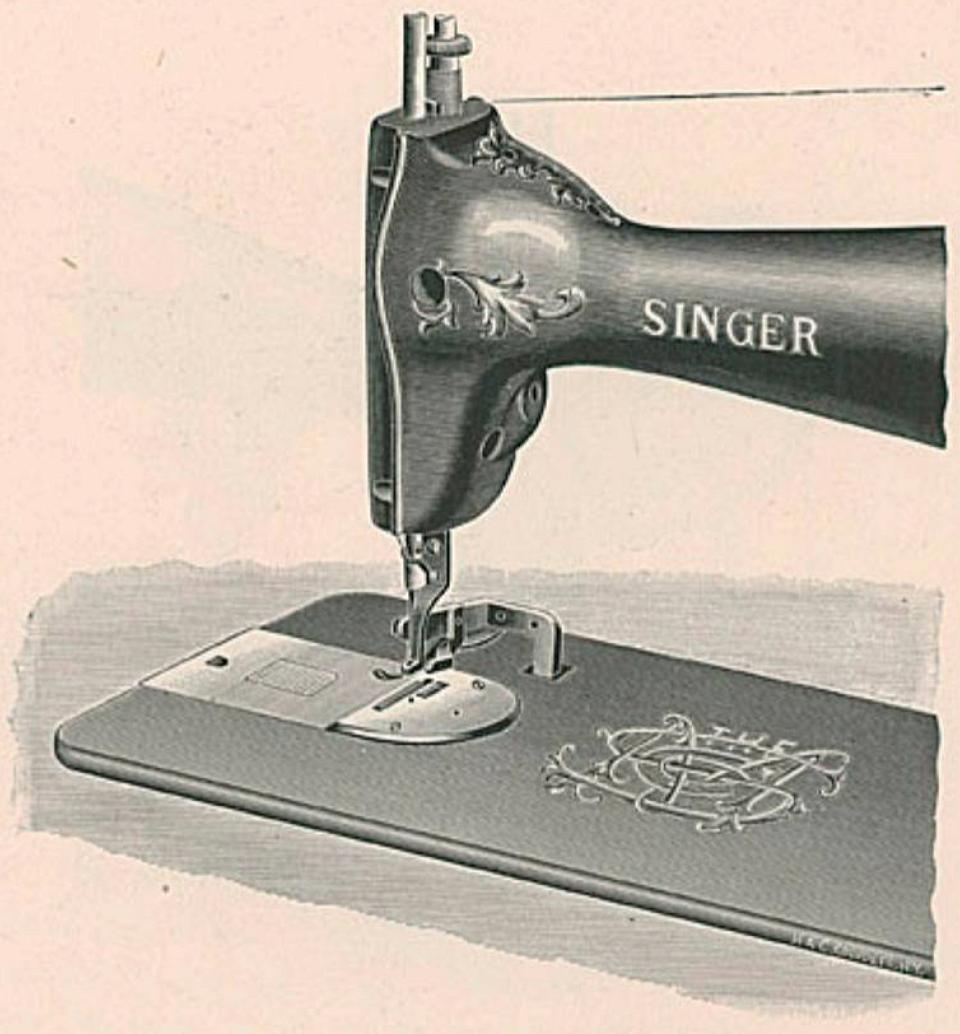

MACHINE No. 15.40

UPPER AND LOWER FEED.

Alternating Presser.

Machine No. 15-40, illustrated above, has both upper and lower feed, working in conjunction, and a presser that firmly holds the fabric to the bed during the formation of the stitch; the presser is raised with the needle so as to permit free movement of the material by the simultaneous action of the upper and lower feed mechanism working alternately with the presser. This alternate action secures the most positive and accurate movement of two or more plies of fabric, preventing puckering, freely passing inequalities of thickness and carry. ing all the plies uniformly so that they are even at the end of the seam.

It is especially useful in binding Corsets as it will stitch the binding around curved edges, attaching it very smoothly and uniformly.

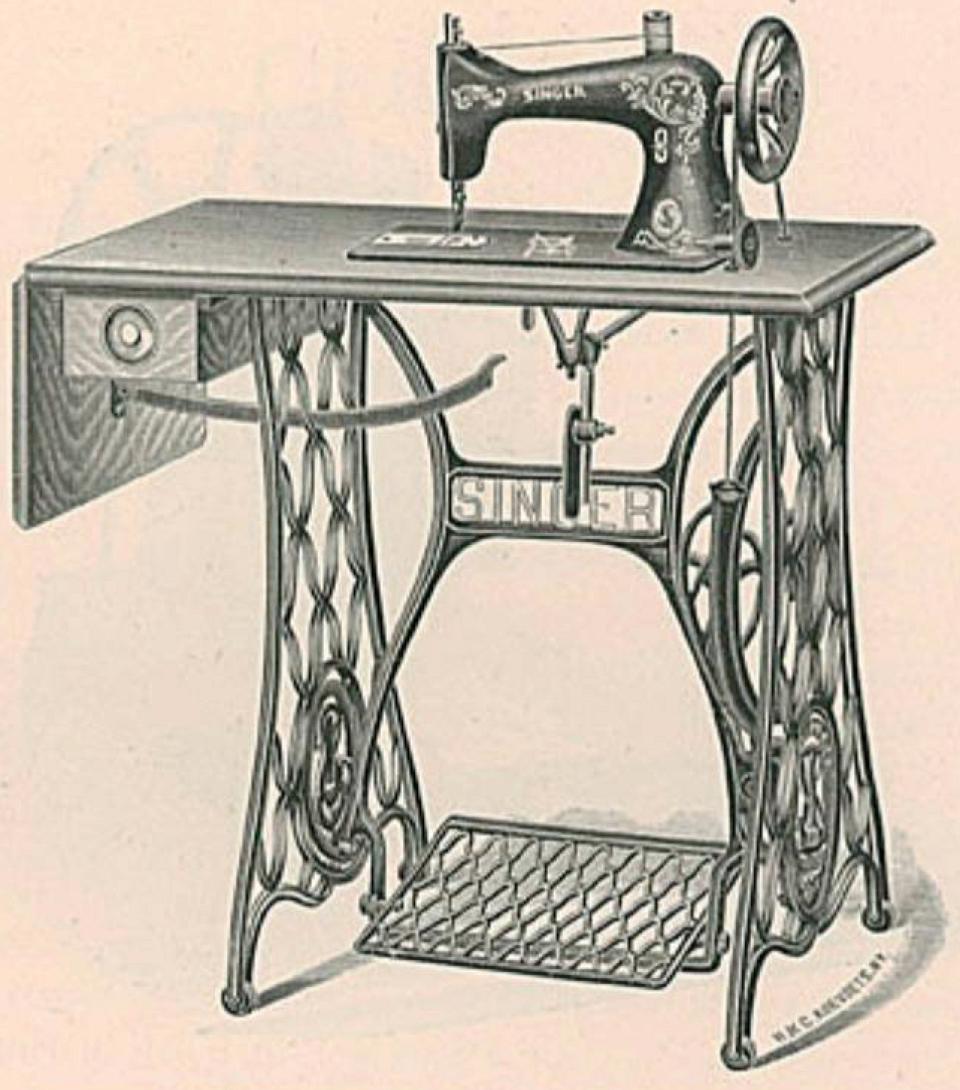

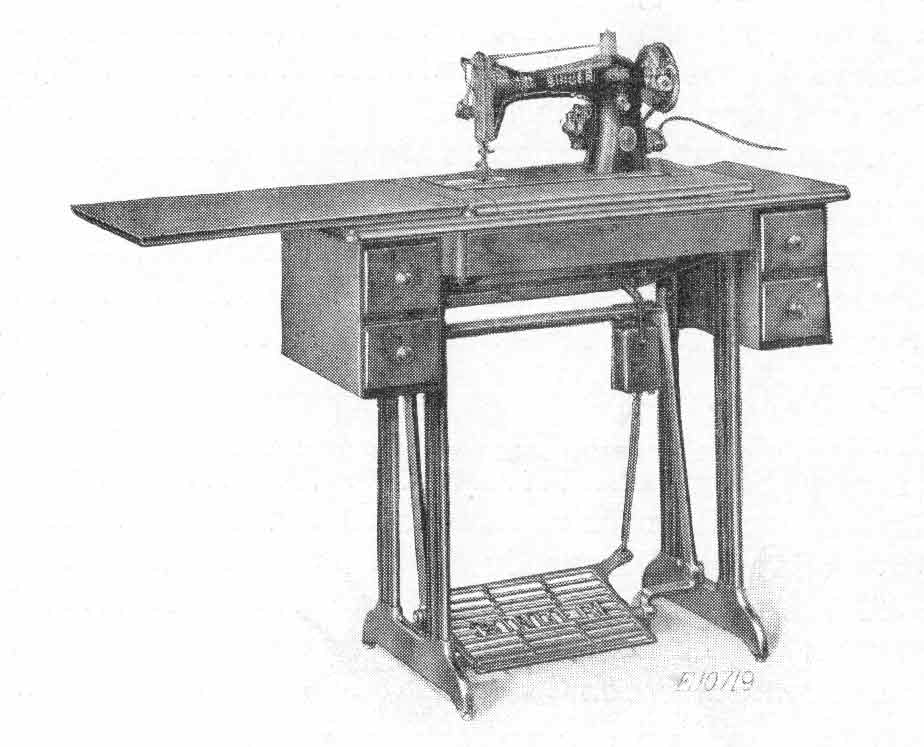

MACHINE No. 15-41

ON STAND

The machines of Class 15 are especially adapted, by their light-running qualities, for operation by foot power and they are extensively used in this manner for manufacturing purposes. For operation by foot power they are furnished with stands and plain table; the balance wheel is fitted so that it can be run loose on the shaft for the purpose of winding bobbins without operating the machine.

The above illustration represents Machine No. 15-41 on stand with Ash table (No. 5204). The table is 16 inches wide and 31 1/2 inches long with the end leaf down; with the leaf up it is 41 inches long. A solid Black Walnut table (No. 5091) is also furnished, measuring 16x29 inches.

MACHINE No. 15-42

FEED FROM LEFT TO RIGHT.

Machine No. 15-42, illustrated above, is specially designed for fine lockstitching at high speed in Collar and Cuff manufacture. Although but recently introduced, its practical operation is so satisfactory that it is rapidly coming into extensive use.

The bed of the machine is raised from the table and stands on an iron base, the end of the bed being towards the operator and the feed is from left to right.

This arrangement enables quick access to bobbin and greatly facilitates the fast handling of work, thus securing increased production

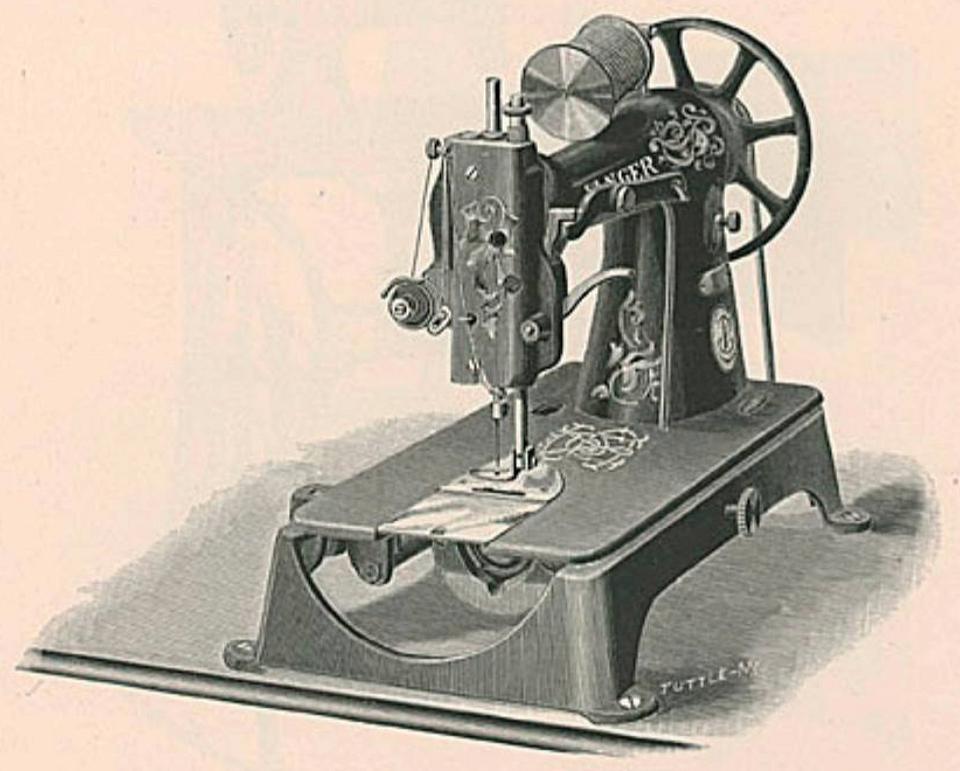

The following is lifted from John Langdon's Comprehensive Model List

IF

'Improved Family'

(USA)

(USA)

|

1879-95 | Domestic | Oscillating long beak shuttle. Lock stitch; drop feed. Serpentine 'fiddle'-shape bed plate. Old style (simple) bobbin winder. Treadle and some hand crank. Became the class 15. Electric version shown. (Photo: Pat Nordmark) | 15x1 |

| IF 'Improved Family' (Kilbowie) | 1879-? | Domestic | As the USA version. Parts were also available to convert machine to alternating presser, wheel feed and/or with a cutting device for manufacturing purposes. | |

IF 'Improved Family' (Electric)

|

1889 | A couple (at least) of examples exist, both using a Gramme armature motor. An early attempt at electification - see also class 27 electric. (Photo: West Dunbartonshire Libraries & Museums) | ||

| 15- class (USA) | 1895-1957 | Domestic & industrial | Oscillating shuttle. Knee lifter on 'industrial' machines. Lock stitch; drop feed. Bed 14 5/8" by 7" wide, with 6 1/2" space at right of needle. Some models "For use in manufacturing light fabrics and leather" otherwise for cloth. ( Download generic manual ) | - |

| 15K class (Kilbowie) | 1890 - 1957 | Domestic & industrial | Same as US version: tension on side face plate. Threads left to right. Vertical oscillating (C.B.) shuttle. Somevarieties have long beak shuttle. Bobbin cases vary. Many light industrial models in the class. ( Download generic class 15 manual ) | - |

| 15N | 1982 | Domestic | See 15K | 15x1 |

| 15NL, CL | 1985-90 | Domestic | Oscillating hook. For treadle. | 15x1 |

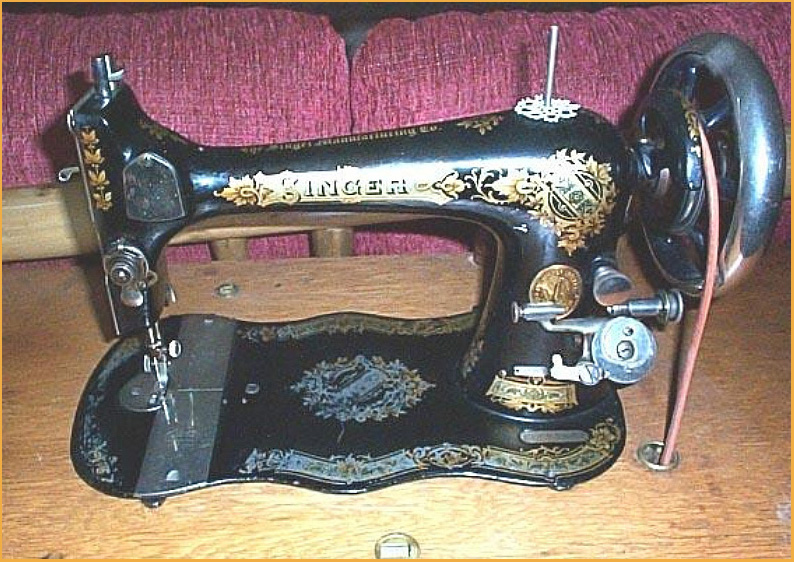

| 15-1 | 1879-95 | Domestic | H.O., for family use. Long beak shuttle. Spoked wheel. | 15x1 |

| 15K3 | Domestic | Oscillating shuttle. Drop feed; for family use. | 15x1 | |

| 15K4 | Domestic | Drop feed; for family use. | 15x1 | |

| 15K5 | Industrial | Drop feed; oscillating shuttle. For general cloth work. | 16x1 | |

| 15K9 | Industrial | Drop feed; high point oscillating shuttle. For general cloth work. | 206x11 | |

| 15-11 | Domestic | C.B., H.O., for family use. "1 o'clock" bobbin case finger. | ||

| 15K15 | Industrial | Drop feed; oscillating shuttle. For general cloth work. | 16x2 | |

| 15K17 | Industrial | Wheel feed; oscillating shuttle; roller presser. For light leather work. | 16x2 | |

| 15-22 | Industrial | High point oscillating shuttle. Drop feed ("fore & aft"). Reactangular bed. For collar and cuff work | 15x1 | |

| 15-22 | Domestic | Long beak shuttle; drop feed. H.O. (for family use). | 15x1 | |

| 15-23 | Industrial | Drop feed. Speed 1500. For cloth. | 16x1 | |

| 15-24 | Industrial | Drop feed. Speed 1500. For leather. | 16x2 | |

| 15K24 | Domestic | C.B. shuttle. Drop feed for family use. | 15x1 | |

| 15-25 | Industrial | Wheel feed; for leather. Speed 1500. | 16x2 | |

| 15K25 | Domestic | C.B. Shuttle. | 15x1 | |

| 15-26 | Industrial | Drop feed; trimming attachment. Speed 1400. For leather. | 16x2 or 16x22 | |

| 15K26 | Domestic | C.B. Shuttle. Drop feed for family use. | 15x1 | |

| 15-27 | Industrial | Drop feed; trimming attachment. Speed 1400. For leather. | 16x2 or 16x22 | |

| 15K27 | Domestic | C.B. Shuttle | 15x1 | |

| 15-28 | Industrial | Drop feed; C.B. shuttle; For general cloth work. Alternating pressers. Speed 1400. | 16x1 or 16x2 | |

| 15K28 | Industrial | No alternating presser! | 16x1 | |

| 15-29 | Industrial | Drop feed; upper and lower alternating pressers. Speed 1400. | 16x1 | |

| 15K29 | Industrial | 16x73 | ||

| 15-30 | Industrial (!) | C.B. Drop feed. Speed 1600. For cloth. | 15x1 | |

15-30

|

1895-1933 | Domestic (!) | Family; C.B. shuttle; drop feed; H.O. (head only - treadle or hand). No reverse feed. "1 o'clock" bobbin case finger. ( Download manual ). | 15x1 |

| 15K30 | Industrial (!) | Wheel feed, roller presser; C.B. shuttle, for light leather work. | 16x2 | |

15-31

|

Domestic | Drop feed; C.B. shuttle. Speed 1600. Max stitch length 5 1/3 to the inch. For cloth. (02/55) | 15x1 | |

| 15-32 | Industrial | C.B. Drop feed. Speed 1600. For leather. | 16x74 | |

| 15-33 | Industrial | C.B. Wheel feed. Speed 1600. For leather. | 16x74 | |

| 15-34 | Industrial | C.B. Drop feed. Speed 1600. For collars and cuffs. | 16x83 | |

| 15-35 | Industrial | C.B. Drop feed. Speed 1600. Max stitch length 5 1/3 to the inch. For shirts, linen and cotton goods. (02/55) | 16x73 | |

| 15-36 | Industrial | C.B. Wheel feed. Trimming attachment. Speed 1400. For glove work, C.S.M. | 16x97 | |

| 15K36 | Industrial | Drop feed; C.B. shuttle; roller presser. For light leather work. | 16x2 | |

| 15-37 | Industrial | C.B. Drop feed; trimming attachment. Speed 1400. For leather. | 16x74 or 16x86 | |

| 15-38 | Industrial | C.B. Wheel feed; trimming attachment. Speed 1400. For leather. | 16x74 or 16x86 | |

| 15-39 | Industrial | C.B. Drop feed; alternating pressers. Speed 1400. | 16x73 or 16x74 | |

| 15-40 | Industrial | C.B. Drop feed; upper and lower alternating pressers. | 16x73 | |

| 15-41 | "For home manufacturing" | C.B. shuttle; H.O. fitted for round shank needles. C.S.M. | 16x73 | |

| 15-42 | Industrial | Drop feed from left to right. Speed 1600. For shirt and collar work. | 16x74 or 16x83 | |

| 15-43 | "For home manufacturing". | Long beak shuttle; drop feed; H.O. fitted for round shank needles. | 16x1 | |

| 15-44 | Industrial | C.B., drop feed from left to right; base cut away at right of needle. For collar and cuff work. "For home manufacturing". | 16x73 or 16x83 | |

| 15-50 | Domestic | C.B. Shuttle; drop feed. H.O. with hand attachment. | 15x1 | |

| 15K51 | Industrial | Drop feed ("fore & aft"). C.B. shuttle. For collar and cuff work. | ||

15-62

|

Domestic | 15x1 | ||

| 15K62 | Industrial | Drop feed left to right. C.B. shuttle. For shirt and collar work. | 16x1 | |

| 15K65 | Industrial | For general sack and hosiery work. Chain stitch - 3 to 18 to the inch with thread nipper. "Can be supplied with fittings for double chain stitch..." (when ordered). Speed 2500. (10/1952) | ||

| 15K66 | Industrial | For dye and hosiery work requiring a very slack thread. Single thread chain stitch - 3 to 18 to the inch. (10/1952) | ||

| 15K70 | Industrial | C.B. Shuttle. Similar to 15K26 but with with different presser foot; throat plate etc. Lighter pulley. For Japan - 1/4" stitch for kimonos, etc. | 15x1 | |

| 15K71 | Domestic | C.B. Shuttle. Drop feed for family use. | 15x1 | |

| 15K72 | Industrial | C.B. Shuttle. As 15K26 but with different presser foot; throat plate etc. Heavy pulley. For Japan - 1/4" stitch for kimonos and sim. | 15x1 | |

| 15K73 | Industrial | C.B. Shuttle. Similar to 15K26, For Japan - 1/4" stitch for kimonos and sim. | 15x1 | |

| 15-75 | Domestic | CB. "11 o'clock' bobbin case finger.Reverse feed. Same as 15-125 but with ext. motor. Solid wheel. Feed dogs drop, contolled within bobbin area. | 15x1 | |

| 15K80 | 1910-56 | Domestic | C.B. Shuttle; drop feed. Dogs do not drop. "1 o'clock" bobbin case finger. Spoked wheel. | 15x1 |

| 15K81 | Domestic | C.B. shuttle. Drop feed for family use. | 15x1 | |

| 15K82 | Domestic | C.B. shuttle. Drop feed for family use. | 15x1 | |

| 15K83 | Industrial | Similar to 15K26. For Japan - 1/4" stitch for kimonos and sim. Light pulley. | 15x1 | |

| 15K84 | Industrial | Similar to 15K26. For Japan - 1/4" stitch for kimonos and sim. Heavy pulley. | 15x1 | |

| 15K85 | Industrial | Similar to 15K26. For Japan - 1/4" stitch for kimonos and sim. 3 1/4" diameter pulley. | 15x1 | |

| 15-86 | 1895-1933 | Domestic | C.B. Shuttle; drop feed. Treadle. | 15x1 |

15-87

|

Industrial | C.B. Shuttle; drop feed. With BR Family sewing machine motor. ( Download manual ) | 15x1 | |

15-88

|

1933-41 | Domestic | C.B. Shuttle. Drop feed. "11 o'clock" bobbin case finger. Spoked wheel. Round plate; with reverse feed; feed dogs drop. Treadle or electric. Photo: Bernard Pokorski . | 15x1 |

| 15K88 | Domestic | C.B. shuttle. Reverse feed. “Balanced” machine. Family use. | 15x1 | |

| 15-89 | Domestic | As 15-88 but with hand-crank. Feed dogs drop. Reverse feed.. | 15x1 | |

| 15K89 | Domestic | C.B. shuttle. Reverse feed. “Balanced” machine. Family use. | 15x1 | |

| 15-90 | Domestic | C.B. shuttle. Reverse feed. '11 o'clock' bobbin case finger. Solid balance wheel. External electric motor. Feed dogs drop. | 15x1 | |

| 15K90 | Domestic | C.B. shuttle. Reverse feed. “Balanced” machine. Family use. | 15x1 | |

| 15-91 | 1930-1956 | Domestic | C.B. shuttle. Reverse feed. “Balanced” machine. P.G. motor and moulded Singerlight. Gear driven; built in (potted) motor; reverse feed; feed dogs drop. Solid balance wheel. '11 o'clock' bobbin case finger. Feed dogs drop. ( Download manual ) | 15x1 |

| 15K92 | Domestic | C.B. shuttle. Reverse feed. “Balanced” machine. Solid hand wheel. P.G. motor and Singerlight. Family use. | ||

| 15K95 | Industrial | Drop feed, C.B. shuttle, with reverse. For stitching or joining tape belts on spinning and twisting frames. | 16x1 | |

| 15-96 | Domestic | "1 o'clock" bobbin case finger. Spoked balance wheel. Dogs do not drop. | ||

| 15-97 | Domestic | Belt drive. Reverse. Feed dogs drop. As 15-96 but with B.R. motor and Singerlight. Solid balance wheel. '1 o'clock' bobbin case finger. Dogs do not drop. belt drive. | 15x1 | |

| 15-98 | Domestic | For family use. C.B. shuttle. Drop feed. “Balanced” machine. As 15-96 with hand attachment. Dogs do not drop. | 15x1 | |

| 15K110 | 1957-63 | Domestic | C.B. oscillating shuttle. Cam take-up. Family use. Reverse feed. Solid balance wheel. 1 o'clock bobbin case finger.Feed throw out device (dogs drop) for darning and embroidery. (knob on the bed). | 15x1 |

| 15K111 | Domestic | C.B. oscillating shuttle. Cam take-up. Reverse feed. Solid balance wheel. '1 o'clock' bobbin case finger. Feed throw out device (dogs drop) for darning and embroidery (knob on the bed). | 15x1 | |

| 15K112 | 1958-64 | Domestic | C.B. oscillating shuttle. Cam take-up. '1 o'clock' bobbin case finger. Solid balance wheel. Reverse feed. Feed throw out device (dogs drop) for darning and embroidery (knob on the bed). | 15x1 |

| 15-125 | 1955-58 | Domestic | C.B. oscillating shuttle. Solid balance wheel. '11 o'clock' bobbin finger. Has reverse feed; green; electric; Feed dogs drop, but control is underneath in bobbin area. Same as 15-75 but with potted motor. Dogs drop. I am grateful to BJ Gates for the information | 15x1 |

| 15K128 | Industrial | For cloth. Drop feed. Max stitch length 5 to the inch. Knee lifter. C.B. shuttle. Speed 1800. (07/1953) | ||

| 15K191 | Domestic | Reversible drop feed. C.B. shuttle. Hand attachment. Available with ride-on push truck. For joining tape belts on spinning and twisting frames. | 15x1 | |

'Improved Manufacturing'

|

c.1879- | Industrial | Originally 'fiddle' base. Base (of most models) = 19 1/2" x 8 1/2". "It is larger and stronger than the IF (Improved Family), but light running and with more room under the arm..." Parts were available to convert machine to alternating presser, wheel feed, roller presser etc. Became the Class 16. |