Class 31

THE machines of Class 31, for general lock-stitching in cloth or leather, are especially designed for operation by power at high speed and they are the fastest lock-stitch sewing-machines in the market. They not only show the most judicious application of material to best resist strain and secure absolute stability but all running parts are carefully balanced so as to procure perfect equilibrium under the highest motion. They require the least power for their operation, and the excellence of material and workmanship guarantees greater durability and least cost for repairs.

Although of recent design, these machines have obtained prompt recognition by the trade and are extensively used by manufacturers of Clothing, Cloaks, Overalls, Suits, Skirts, Waists, Costumes, Bathing Suits, Shirts, Knit goods, Mackintoshes, Cardigan Jackets, Oiled Clothing, Leggins, Over-gaiters, Hunting goods, Corsets, Gossamers, Bedding, Blankets, Upholstery, Canvas goods, Carriage Robes, Horse Clothing, etc.

The steadily increasing sales of these machines and the declared satisfaction of manufacturers who use them constitute the best evidence of their superiority both in scientific principle and mechanical detail.

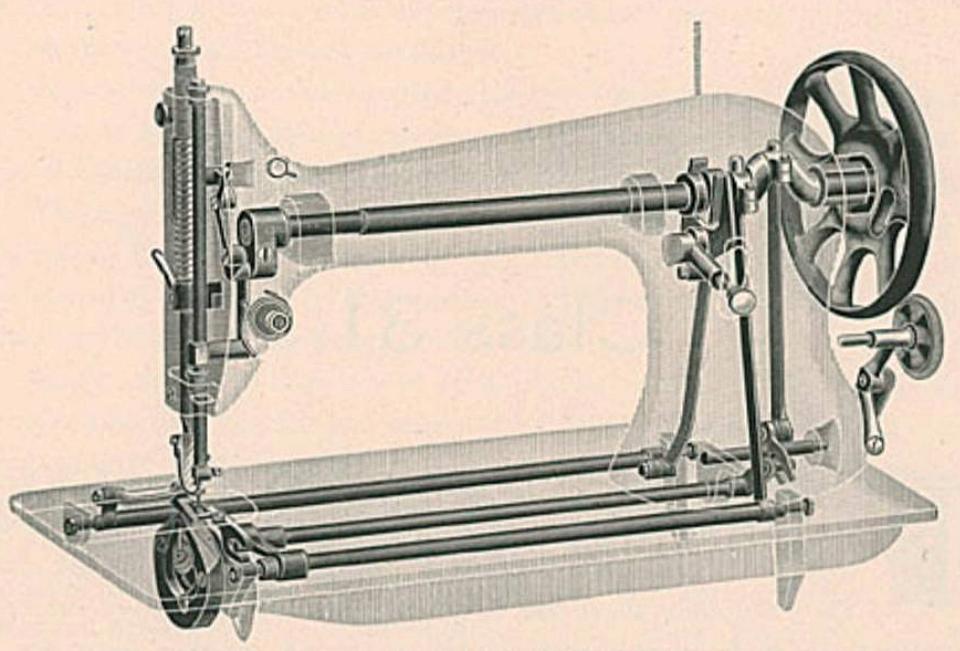

MACHINE No. 31-3

SHOWING INTERIOR MECHANISM.

The above illustration shows the best principles of stitching mechanism, successfully combined to obtain highest efficiency, and using the smallest number of wearing parts, all capable of easy adjustment. The main driving shaft has three bearings, which entirely prevent springing.

A scientific distribution of metal is combined with accurate balancing of all running parts so as to secure utmost strength and stability under high speed, these advantages being comprised in a design of handsome appearance and great convenience.

The Oscillating Shuttle mechanism is scientifically and mechanically perfect. Through its use there is but one simple conversion of motion-_from rotary to oscillating-between the driving and the stitching points. There is no variable speed nor indirect mechanism required for transforming movement. Therefore this machine requires the least power and can be effectively used, without change of adjustment, on either light or heavy fabrics.

The perfection of the stitch-forming mechanism and its accurate thread. controlling devices permit the use of lighter, weaker, and consequently cheaper thread than any other high-speed machine.

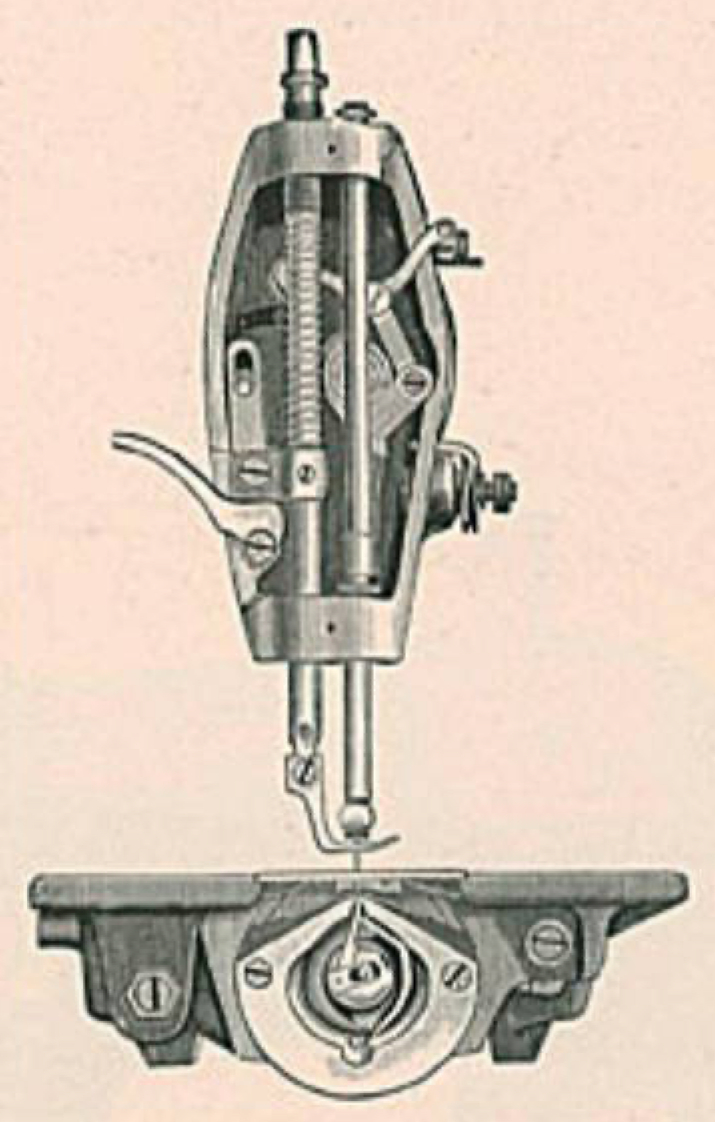

MACHINE NO. 31-3

END SECTION. FACE PLATE REMOVED.

The link thread take-up used on machines of Class 31 is the most efficient device ever constructed for this purpose; it consists of a light and strong lever and link, working silently, without use of cam or spring. It is capable of highest speed without vibration of machine and with least friction and wear of parts.

The shuttle is made of one solid piece of steel, hardened and polished; its simple and regular motion about the central bobbin requires the least power of any and is the most efficient.

The bobbin has capacity for 100 yards of No. 60 cotton, and secures central and straight delivery of thread to material under all conditions.

The four-motioned drop-feed causes direct, positive and exact movement of the material in a perfectly straight line.The tension adjustment is very conveniently located on the front of the arm.

The knee-lift enables instant raising of the presser-foot, by means of kneepressure against a lever hanging beneath the table, thus leaving the operator's hands free and greatly promoting facility and convenience in handling the work.

The Automatic Tension-Release acts in conjunction with the lever for raising the presser-foot. When this lever is lifted the tension discs are automatically opened and allow free passage of the upper thread, so that it can easily be drawn down by the operator, as desired.

All danger of withdrawing thread from the needle is thus obviated, the correct tension being instantly restored when the presser-foot is lowered. The saving of time and consequent increase of product through the use of this device are obvious advantages.

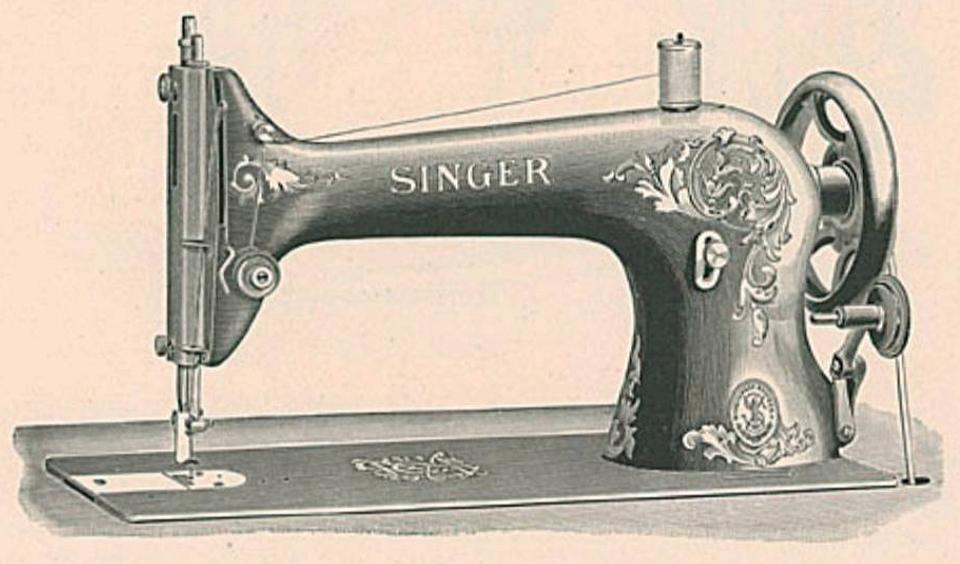

MACHINE No. 31-3

FOR GENERAL STITCHING BY MANUFACTURERS.

All wearing parts of the machines in Class 31 are thoroughly hardened and highly finished, securing perfect ease of motion and great durability.

Machine No. 31-3 is for general stitching on cloth and has drop-feed and stationary presser. Machine No. 31-8, also for cloth, has its feed mechanism arranged so that its motion can be instantly reversed without stopping the machine, thus enabling doubling or staying the seam at any point.

For leather work there are two varieties of machines in this class; machine No. 31-6 has drop-feed and machine No. 31-7 has wheel-feed, both being provided with roller presser.

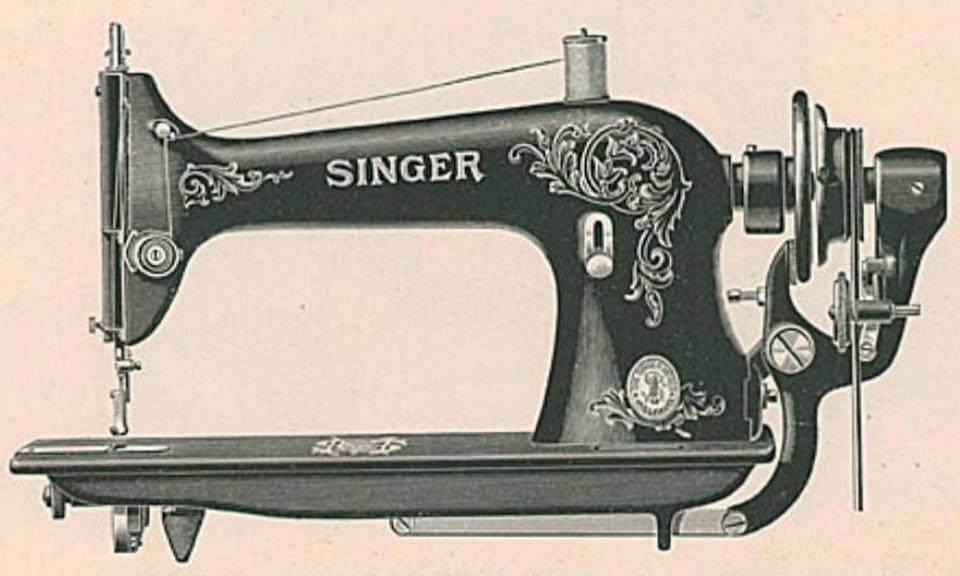

MACHINE No. 31-3

WITH SINGER DRIVING ATTACHMENT.

The above illustration represents a machine of Class 31 fitted with the latest form of Singer Driving Attachment, the most efficient appliance yet devised for the quick application or release of motion in the most effective manner.

The machine can be started or stopped instantly by very light movement and pressure of foot-treadle connected to the attachment.

The whole attachment, excepting the treadle, is on the machine, which may be turned back for oiling or cleaning without removal of belt.

The self-feeding oiling device is the most reliable and economical in use, being especially distinguished for its absolute cleanliness, an essential feature in most uses of the sewing-machine, especially on white goods.

MACHINE No. 31-4

FOR FANNING AND OTHER FANCY STITCHING.

It is a well established fact that those goods which are finished in a manner best calculated to please the artistic sense of their users, easily become the most popular.

No form of ornamentation on textile material appeals more forcibly to this sense than handsome needlework neatly accomplished in appropriate designs and colors.

Such designs may be easily and effectively produced by Machine No. 31-4 and shrewd manufacturers will readily see the various uses to which it may profitably be applied in the manufacture of Corsets, Suspenders, Draperies, Curtains, Portieres, Tapestries, Lambrequins, Piano Covers, Carriage Cloths, Uniforms, Badges, Regalia, Handkerchiefs, Infants' Clothing, Table Covers, Mats, etc.

This machine has no feed, but the fabric is moved by the operator in any direction and to any distance required for the formation of a stitch in any desired length, the needle descending to make it at the will of the operator when the fabric is adjusted by the hand to receive the needle-action at the proper point.

The needle passes through a cylindrical presser that automatically rises and falls with the needle, holding the fabric to the bed just long enough for the stitch to be made and rising to allow free movement of the fabric to the point at which it is desired to make the next stitch. The round point of the presser is only one-eighth of an inch in diameter so that the work is not concealed and the stitch can be accurately located on the fabric.

A rocking treadle on the floor is connected to positive mechanism that instantly clamps and unclamps the driving pulley so that the needle action is completely controlled by the operator by means of " heel and toe " pressure on this treadle.

Ordinarily the machine stops at the completion of each stitch, the pressure on the treadle for starting the machine being made alternately by the heel and toe pressing the treadle down as far as it will go in each direction.

If the treadle is held by the feet in a horizontal position the machine will not stop, but will continue to form stitches until the treadle is pushed down in one direction or the other.

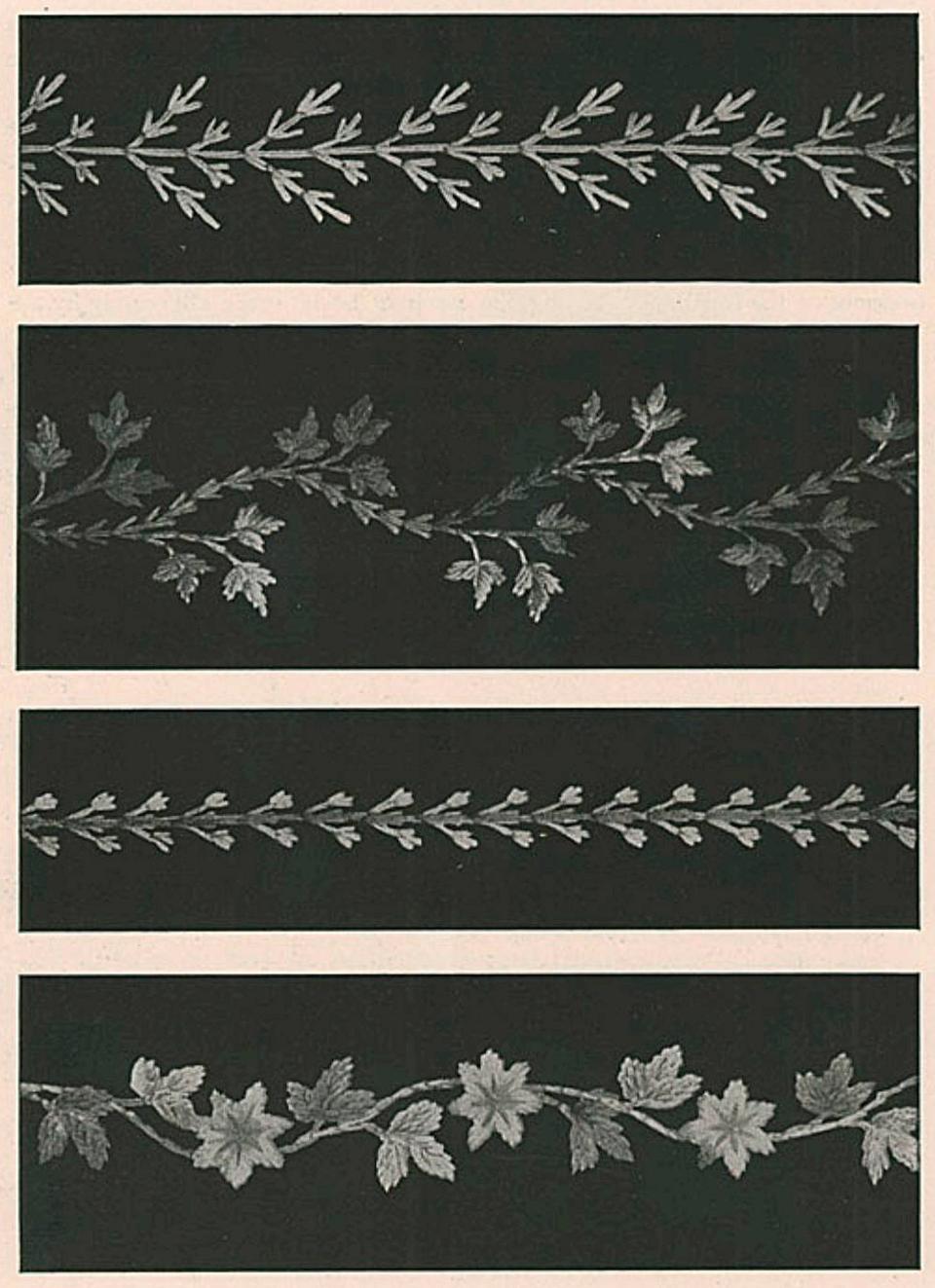

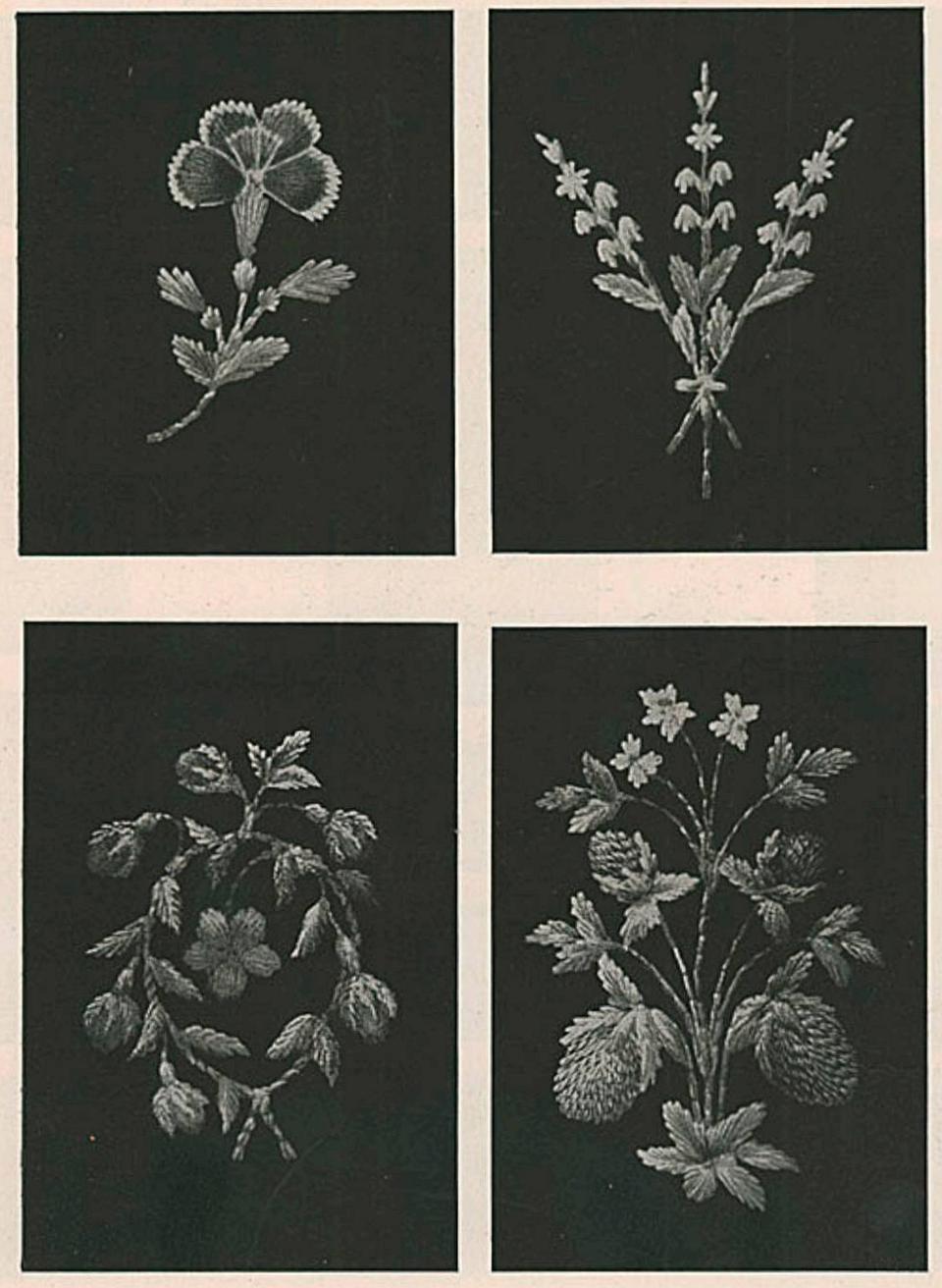

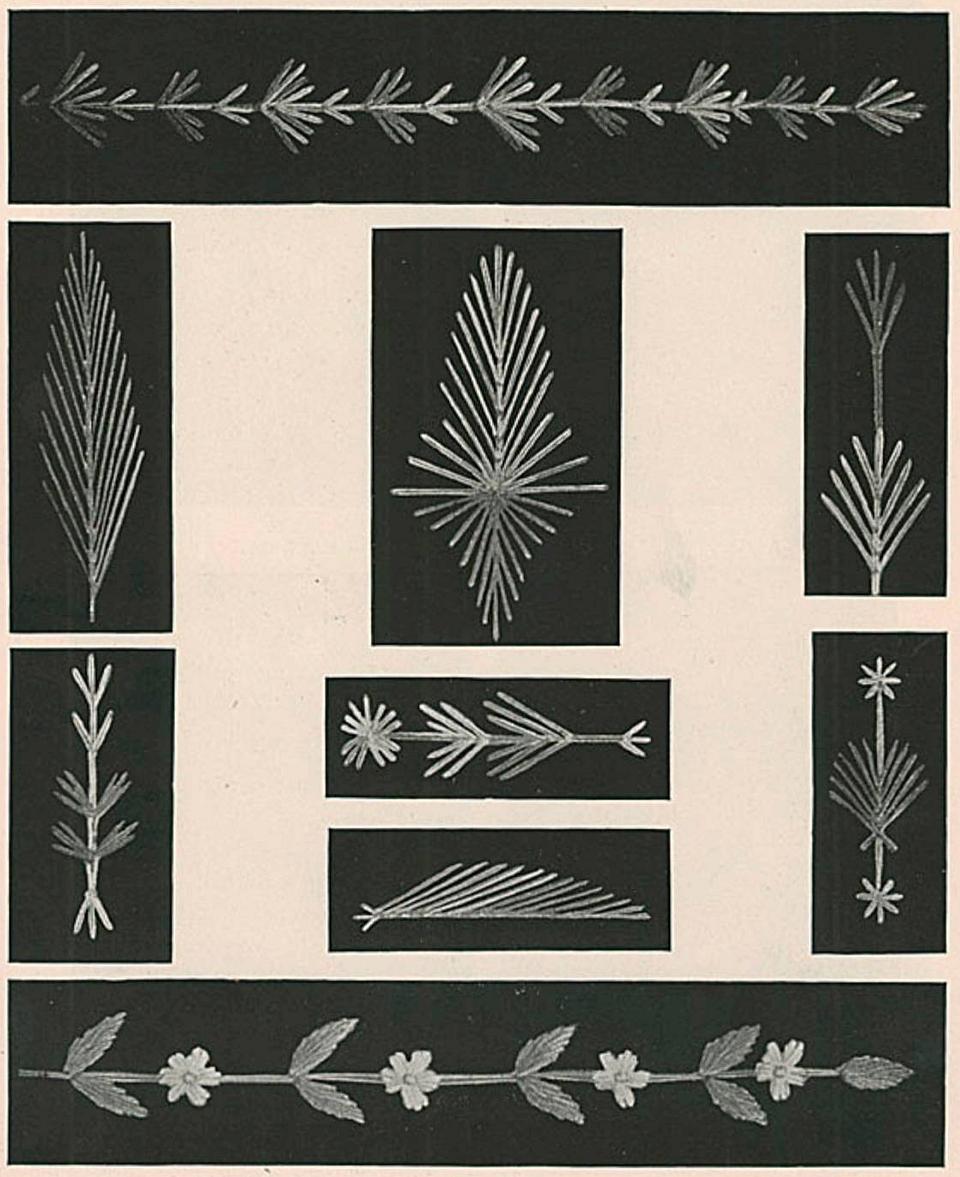

The following illustrations are from photographs of factory work with this machine.

The stitches are usually made with silks of contrasting and harmonious colors.

PHOTOGRAPHIC EXAMPLES OF STITCHING PERFORMED ON MACHINE No. 31-4.

PHOTOGRAPHIC EXAMPLES OF STITCHING PERFORMED ON MACHINE No. 31-4.

PHOTOGRAPHIC EXAMPLES OF STITCHING PERFORMED ON MACHINE No. 31-4.

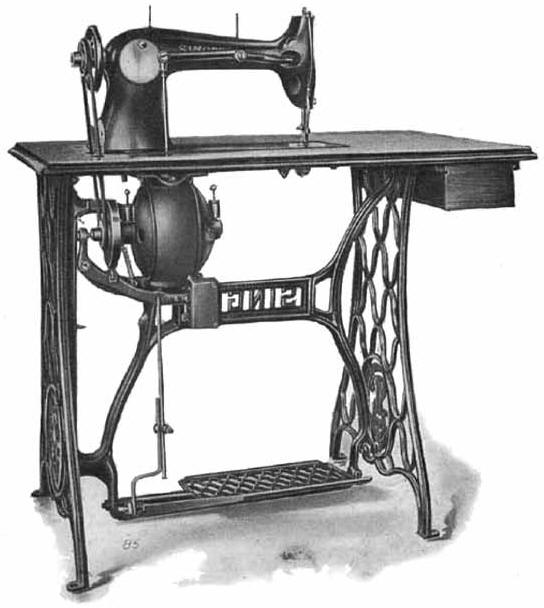

Model 31-15

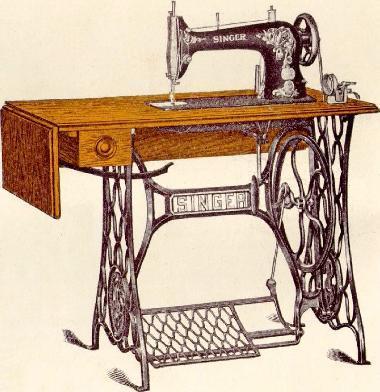

The Tailor's Machine on Table No. 5231

(Picture Courtesy of Dorothy Brumleve)

The table shown is a very convenient and popular form for the use of Tailors and other manufacturers handling large quantities of material in irregular form.

With leaves down, this table is 38 inches long by 19 inches wide.

With leaves up, it is 48 inches long by 25 inches wide, thus affording ample room for easy and convenient handling of this class of work.

Class 31 on converted treadle with Diehl Manufacturing motor; available in AC or DC (1906)

The following is lifted from John Langdon's Comprehensive Model List

| 31- (class) | For cloth, leather, coated fabrics, etc. as described. Lock stitch. Short beak oscillating shuttle. Central Bobbin. Link take up. Drop feed unless specified. Bed 18 3/4" long, 7" wide. Space at right of needle 10 1/4". (10/1952) | |||

| 31K (class) | 1901-? | Industrial | Oscillating shuttle. Bed 18" long. 10 1/4" between needle and base of arm. Link take-up (mostly). Three shaft bearings in arm. Knee lifter. | - |

| 31W | Industrial | 16x2 (2083) | ||

31-4

|

||||

31-15

|

Industrial |

(As 31K15). For cloth, tailoring, etc. Clearance under presser foot 5/16". Max. stitch length 5 1/2 to the

inch. Shuttle #19292. Speed 2200 SPI. (10/1952) (

Treadle model

)

)

|

16x87 on power table, 16x73 on foot treadle. | |

| 31K15 | Industrial | The 'Tailor's Machine". Drop feed for cloth work. | 16x87 on power table, 16x73 on foot treadle. | |

| 31-16 | Industrial | Drop feed. Special shuttle and sectional race for easy removal of shuttle. Special presser foot. Oil cup on arm. Bobbin #2996 | ||

| 31K16 | Industrial | Special shuttle and sectional race. Special presser foot. Drop feed. Oil cup. For mackintosh and gossamer rubber work. | 16x87 or 16x88 | |

| 31-17 | Industrial | Drop feed. Bobbin #2996. For leather. | ||

31K17

|

Industrial | Drop feed, Roller presser; heavy bed plate; "high speed" (2000). Max. stitch length 4 1/2 to the inch. Shuttle #19292 For leather work. (10/1952) | 16x6 or 16x26 | |

31-18

|

Industrial | Wheel feed. Bobbin #2996. For leather. | ||

31K18

|

Industrial | Wheel feed. Roller presser; heavy bed plate. Max. stitch length 8 to the inch. Shuttle #19292. For leather work. (10/1952) | 16x6 or 16x26 | |

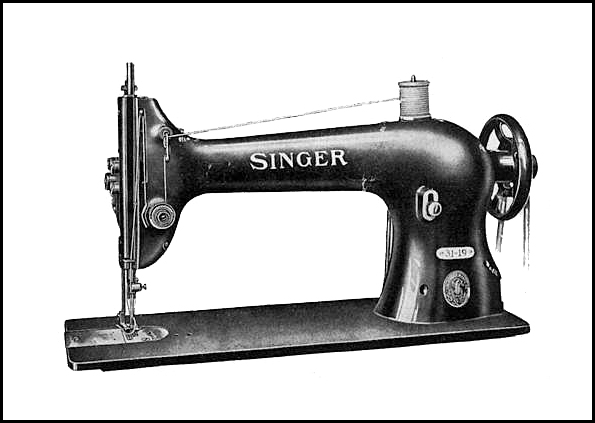

31-19

|

Industrial | One needle, oscillating shuttle, lock stitch; alternating pressers (a vibrating and a lifting presser). Max. stitch length 5 1/2 to the inch. Shuttle #19292. Clearance under the presser foot is 11/32". For sewing coated, enamelled or plain fabrics and lightweight leather, also shoes, mattresses, blankets, awnings, school bags, braces, etc. Speed 2000. (10/1952) | 16 x 87 on power table, 16 x 73 on foot treadle. | |

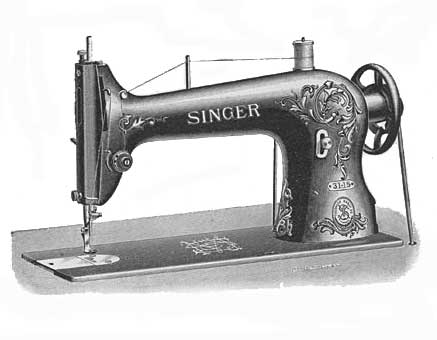

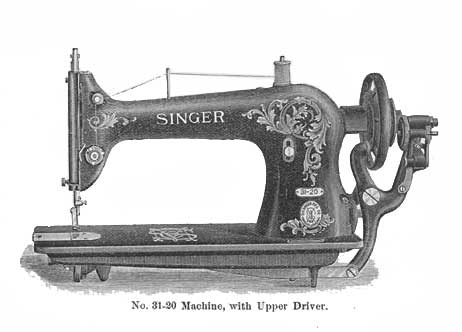

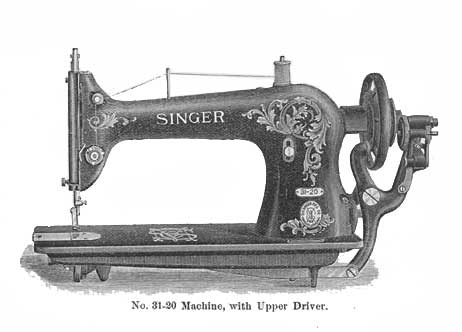

31-20

|

Industrial | For cloth. Throat plate flush with bed. Large bobbin. Max. stitch length 5 1/2 to the inch. Shuttle #20758. Clearance under the presser foot is 5/16". Speed 2200. (In catalog 10/1952) | ||

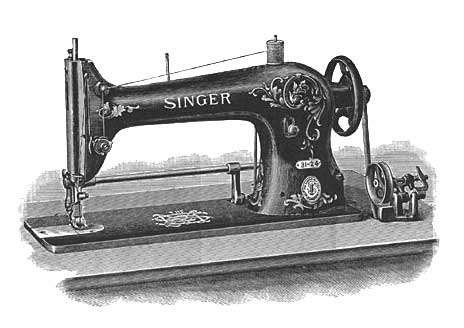

31K20

|

Industrial | Drop feed. Throat plate flush with bed. For cloth work. Speed (10/1952) | 16x87 (2055) on power table, 16x73 on foot treadle. | |

| 31K22 | Industrial | Drop feed. Throat plate flush with bed. High lift presser - clearance 5/16". Max. stitch length 5 1/2 to the inch. Shuttle #20758. For cloaks and other heavy cloth work. (02/52) | 16x113 | |

| 31K24 | Industrial |

Drop feed; positive reciprocating feed slide under presser foot and above the work. For shade work;

felling and seaming fabrics. Speed 2200. (

31-24

)

)

|

||

| 31-27 | Industrial | Drop feed; single needle; positive ruffling mechanism. For full or scant ruffles on thick or thin fabrics, aprons, dresses, etc. Speed 2000. | 16x87 | |

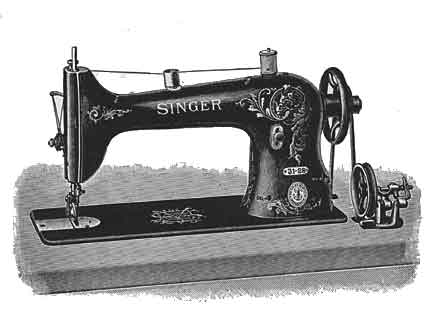

31-28

|

Industrial | Long beak shuttle. Cam thread take-up. Speed 1800. For boots. shoes and general work in light and medium weight leather. | 16x2 | |

31-29

|

Industrial | As 31-28 with wheel feed. | 16x2 | |

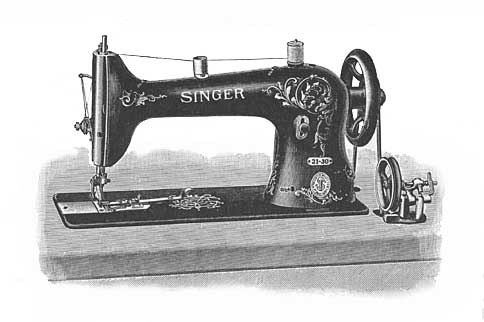

31-30

|

Industrial | Drop feed; long beak shuttle. cam thread take-up; horizontal trimming attachment. For edge and under edge trimming in boots and shoes. | 16x6; 16x26 | |

| 31-31 | Industrial | As 31-30 with wheel feed. | 16x6; 16x26 | |

| 31K32 | Industrial | Same as 31K15 except fitted with reversible drop feed. Speed 2200. (Same as 31-32). (02/52) | ||

| 31-32 | Industrial | Same as 31-15 except fitted with reversible drop feed. For cloth. (10/1952) | 16x87 on power table, 16x73 on foot treadle. | |

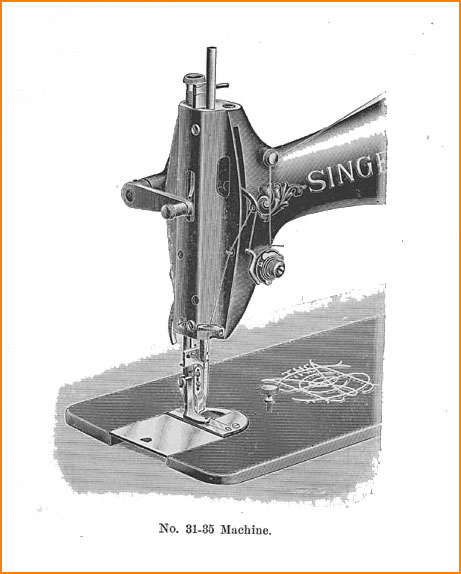

31-35

|

Industrial | |||

31-36

|

Industrial | Drop feed. Bobbin #2996. Trimming attachment. For leather. | ||

| 31-37 | Industrial | For pleating. Makes single, double or triple box pleats or ruffles across strips up to 2 1/4" wide; and on edges of fabrics. Nine pleating cams. Speed 600. (10/1952) | 31x1 | |

| 31-38 | Industrial | Vertical trimmer; wheel feed and Speed 1800. For leather. | 16x6 or 16x26 | |

31-39

|

Industrial | For darning lace curtains. Small needle hole. NO FEED MECHANISM. Speed 1800. | 16x73 | |

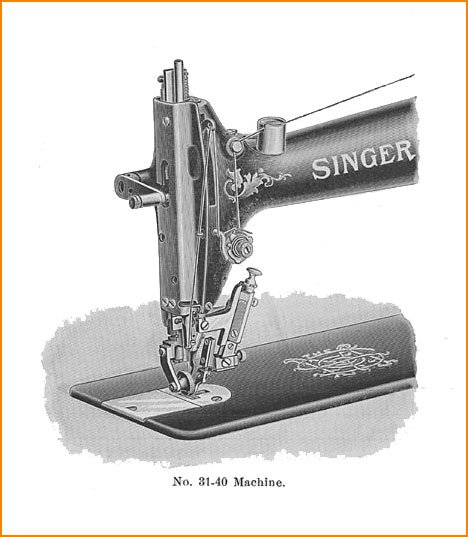

31-40

|

Industrial | |||

| 31-44 | Industrial | Max. stitch length 5 to the inch. Roller presser. Automatic stop motion and thread cutting mechanism. Foot lifter. Speed 1000RPM. For stitching tongues in shoe vamps and other leather work. (10/1952) | 16x10 | |

| 31K45 | Industrial | Wheel feed. Roller presser. Sectional shuttle race; For light work on boots and shoes.. | 16x6 | |

31-47

|

Industrial | Presser foot clearance 3/8" (high lift), otherwise similar to 31-19. Alternating pressers. Shuttle #19292. Speed 2000. For medium and heavy clothing as well as leather and enamelled cloth. (10/1952) | 16 x 113 | |

| 31K47 | Industrial | Same as 31-47. (02/52) | ||

| 31K48 | Industrial | Wheel feed. Roller presser. Max stitch length 8 to the inch. Clearance under roller presser 5/16". Shuttle #19292. For leather work. Speed 2000. (In catalog 02/52) | 16x6 | |

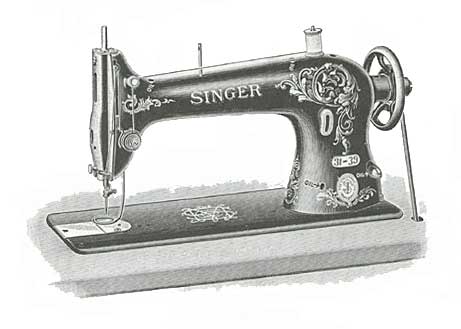

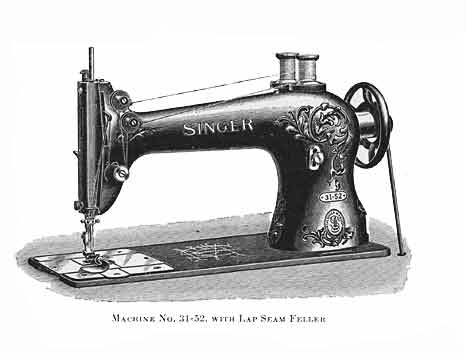

31-52

|

Industrial | Drop feed. Two nededles. Two shuttles. High raise foot. For general work in fabrics. | ||

| 31-53 | Industrial | TWO needles; TWO shuttles. Bobbin #19131. For heavy work only in cloth, Duck, canvas, etc. Gauges from 3/16" to 1 1/4"; throat plate flush with bed. Drop feed. Speed 1800. | ||

| 31-54 | Industrial | TWO needles; TWO shuttles. Bobbin #19131. For cloth. Gauges from 3/16" to 1 1/4"; throat plate flush with bed. Drop feed. Speed 2000. | ||

| 31-55 | Industrial | TWO needles; TWO shuttles. Bobbin #19131. For vamping and staying shoes. Gauges from 1/32" to 3/16" for vamping; 3/32" to 1/4" for staying. Throat plate flush with bed. Drop feed. Speed 1800. | ||

| 31-60 | Industrial | TWO needles; TWO shuttles. Bobbin #19131. For ruffling; for thick or thin fabrics, aprons, dresses, curtains, etc. Positive ruffling mechanism. gauges of machine 1/8" to 3/4". Drop feed. | ||

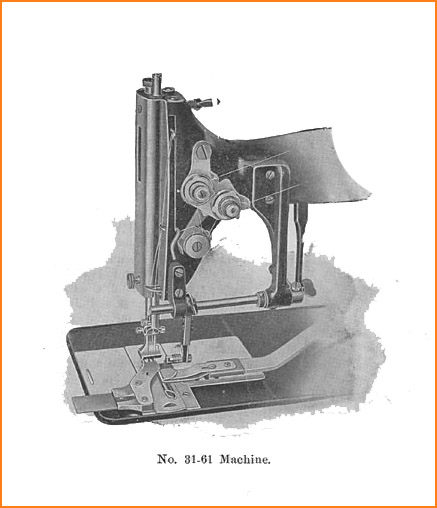

31-61

|

Industrial | |||

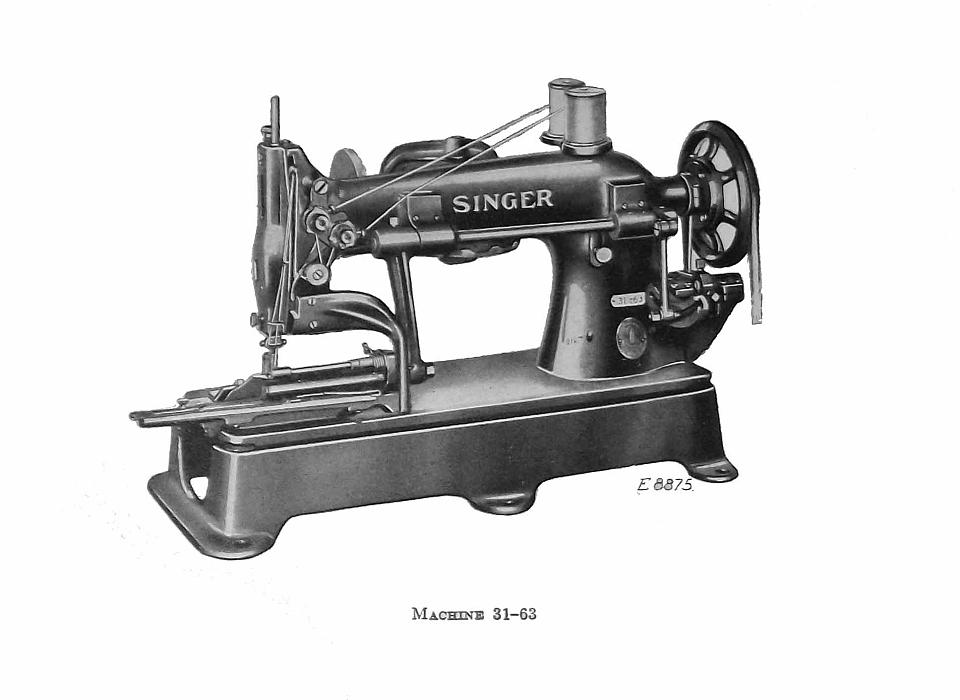

31-63

|

Industrial | For pleating or pleating and stitching aprons, skirts, dresses, etc. Clearance under presser foot 7/32". Two needles. Two shuttles. Can be used for single needle work. Cams supplied for various styles of pleats, Speed up to 450. (In catalog 06/1954) |