How to correctly orient a needle in a machine

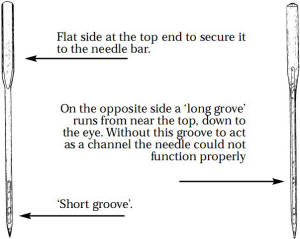

Figure 1

As far as I know, the following details are true for just about all sewing machines ever made. These details will help you determine which way a needle should be inserted into the needle bar of any sewing machine as well as from which side to thread the needle.

The sewing machine will have a hook associated with the bobbin thread. This may be a rotary hook as found on oscillating or rotary machines, or it will be the point of a boat shuttle, or bullet shuttle. These are all different implementations of a hook.

If you refer to Figure 1, you will note that a needle will have a long thread groove down one side.

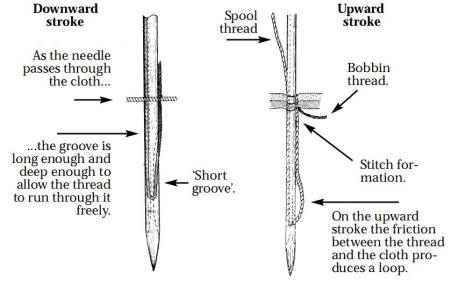

There is usually a short groove and a scarf located on the opposite side of the needle. The short groove/scarf side of the needle always faces the hook. This is the side of the needle which forms the small loop on the upward stroke of the needle as shown in Figure 2.

Figure 2

The hook passes thru this small loop between the thread and the needle. Some older needles do not have a scarf. No matter, the hook always passes by this side of the needle, NOT the long thread groove side.

With the above information in hand, you should be able to remove the needle plate, insert a needle, and watch as you turn the hand wheel slowly by hand which side of the needle the hook passes by.

Once you have determined which side the hook passes by, you then orient the needle so that the scarf side faces the hook as it passes by the needle. This means that the long thread groove side of the needle is on the opposite side.

You always thread the needle through the eye from the long thread groove side of the needle.

Things to look for when selecting an alternative needle

-

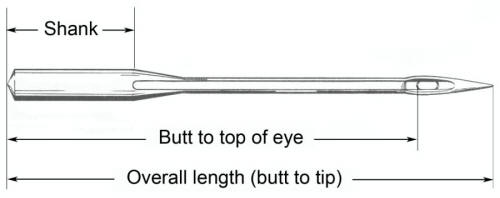

The distance from the butt of the needle to the top of the eye.

The hook or shuttle point must be able to catch the thread loop formed during the upward stroke of the needle. If the loop is too high or too low, the hook will miss the loop and you will get a missed stitch. Sometimes a needle that has too short of a needle eye distance, but which meets all of the other requirements outlined below, can be made to work by scotching the needle down in the needlebar a bit. -

The overall length of the needle.

If the needle length is too long, the point of the needle may still be in the fabric when the feed dogs begin moving the fabric. This can cause missed stitches, puckering and needle damage. A longer needle may also hit a part of the machine on its downward stroke. -

The shank of the needle must fit up inside the needle bar.

This is an easy one! -

Using a round shank needle in the place of a flat shank needl e.

In order to fit up into the needle bar, the shank diameter of a round shank needle must be significantly smaller then the original flat shank needle. You must also orient the needle correctly in the needle bar, as you cannot rely on the flat shank on the needle to do that for you. A smaller diameter shank will move the needle either further away or closer to the hook or shuttle point a smidge. This is not usually a problem, but it may cause missed stitches, or worse, it could run into the hook. So make sure you follow the instructions in the next section to check for problems. -

The original needle did not have a scarf, but the new needle does.

A scarf will increase the distance between the needle and the hook or shuttle point a smidge. This is not usually a problem, but it would cause missed stitches. -

The original needle has a scarf, but the new needle does not.

I doubt you will ever run into this. Just about all new needles have scarfs. However, if you do have this problem then you need to make sure the hook does not run into the needle during sewing. It the hook is adjusted so as to go thru the scarf area of the needle, and there is no scarf area, a collision will occur. A bad thing!

Things to check when testing an alternative needle

-

Insert and orient the needle into the needle bar, but do not thread it.

-

Remove the needle plate and/or bobbin access plate so that you can see the hook and bobbin area inside of the machine.

-

Slowly turn the hand wheel and watch the needle point as it descends into the machine.

-

Make sure the needle point does not run into any part of the machine. This includes the bobbin case, bobbin, shuttle point, rotary hook, or any other machine part. A flashlight and magnifier glass might be required!

-

If everything is OK so far, put the needle plate back on the machine. Then slowly turn the hand wheel again to move the needle thru the up down cycle.

-

On the up stroke of the needle, watch as the point of the needle clears the needle plate (and invisible fabric) and make sure the feed dogs have not begun to move the fabric until the needle is clear of the invisible fabric.

-

If everything is still OK, then you should be able to sew with this alternative needle.

-

There is a very slight chance that you may encounter skipped stitches after this point if the alternative needle changed some dynamic enough that the hook can not catch the top thread during the up and stroke of the needle. One of the following may cause this:

-

The distance from the butt of the needle to the top of the eye is different from the original needle.

-

Switching from a flat shank to a round shank caused the hook to move too far away from the needle.

-

There is no easy solution to this problem of skipped stitches. If you are a sewing machine mechanic, you might be able to re-time the machine if you wish to go that extreme.

-