The Howe Sewing Machine Company "Express"

by Martin Gregory

ISMACS News #101

December 2010

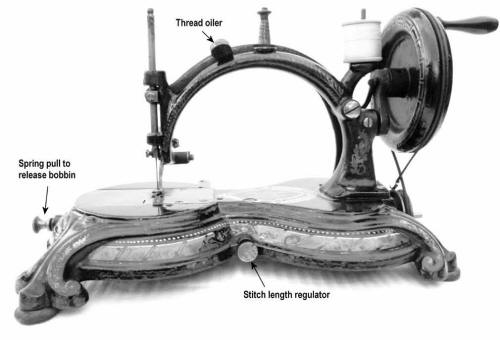

Graham Cresswell has come across a hand machine badged for the Howe Sewing Machine Co. as the 'Express'. This is the first time I have seen a Howe 'Express' in good condition so it warrants an article on its history. My thanks are due to Graham for the photographs which illustrate it.

Three hand machines were marketed by the Howe S. M. Co in the UK in the late 1860s and 1870s; the 'Swiftsure' the 'Little Howe' and the 'Express'. The 'Swiftsure', which carries the patent date 1869, was a registered design (1870) of the Coventry Machinists Co. The 'Little Howe', an improved gear-driven 'Swiftsure' was registered in 1873. Both of these machine use boat shuttles.

Figure 1

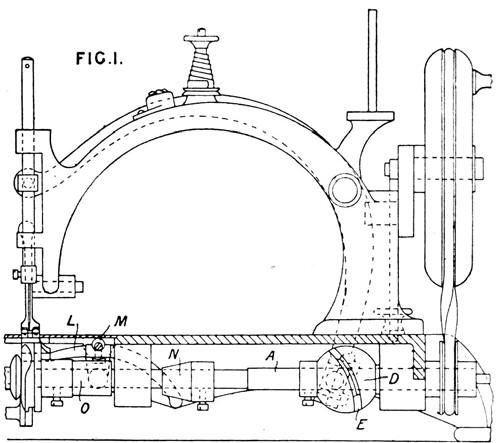

James Starley's patent No. 1678 of May 21st, 1868

The 'Express' is the rarest of the three and follows a patent of James Starley (No. 1678) of May 21st, 1868 (Figure 1). The machine fits the patent drawings so closely that they could have been the working drawings for manufacture. Starley, at this time, was working for the Coventry Sewing Machine Company, whose best known product today is the 'European' free-arm treadle machine patented by Starley and Salisbury in 1861. The Coventry S. M. Co. was not a commercial success, having been formed from the ruins of the European Sewing Machine Co. in Coventry. Sales were not good and, in 1867, the company started making velocipedes and changed its name, in May 1869, to the Coventry Machinists Company. James Starley left in 1870 to start his own company which made such machines as the 'Europa', the 'Queen of Hearts' etc.

Rear view of the 'Express'

At the end of the 1860s, the Coventry Machinists Company claimed to manufacture the 'European', the 'Godiva', the 'Swiftsure' and the 'Express'. Of these four, I have yet to identify the 'Godiva'. So, how did the Rear view of the 'Express' Coventry Machinists Co. 'Express' and 'Swiftsure' come to be badged for the Howe S M Co?

The link is Nahum Salamon. In 1860, Salamon was a patent agent. By 1863, he was the UK Manager for the Howe S. M. Co. and the author of one of the few biographies of Elias Howe written in his lifetime. Remember, Howe sewing machines were made only by the Howe S. M. Co. (Amasa Howe's company) until the formation of the Howe Machine Co. (the ones with the medallion of Elias Howe) in 1867, the year of Elias Howe's death. The Howe S. M. Co. carried on until 1873 when it was sold to the Howe Machine Co. Whilst the Howe S. M. Co. imported treadle machines into the UK they did not manufacture hand machines which had always formed a significant slice of the UK market.

Figure 5

the hinged presser foot assembly

Salamon is listed as a major purchaser of machines from the Coventry company. Maybe, Salamon put money into the ailing business to get the trio of 'Swiftsure', 'Little Howe' and 'Express' manufactured. Certainly, none have turned up badged for anyone other than the Howe S. M. Co. So, I think these machines were made in Coventry for Salamon to sell alongside the treadle machines imported from the USA. The Howe S. M. Co. was sold in 1873 so the production run was very short, from 1868-9 to c1875. The buyer, the Howe Machine Co, imported their smallest treadle machine head, fitted it with hand gear and a cast iron base, and thus had no requirement for a locally produced hand machine. Salamon, out of a job with the Howe S. M. Co, continued to advertise the hand machines for a few years. He joined the Coventry Machinists Co. full time as a director in 1873 and retired as Chairman in 1881.

Figure 4

registered trade mark for the Howe Sewing Machine Co.

The 'Swiftsure'/'Little Howe' is a typical hand machine of the period. The 'Express' is a real oddity. It sews a lockstitch using a rotary hook of the early Wheeler & Wilson pattern. Figs. 2 and 3 show front and back views of the machine. Fig. 4 shows the Howe S. M. Co. decal in the centre of the base.

The company was at 8 Ludgate Street in 1863 and 23 Ludgate Hill at the end of the 1860s; Holborn Viaduct and the street with that name were completed in 1870 and that became the Howe Co's last address.

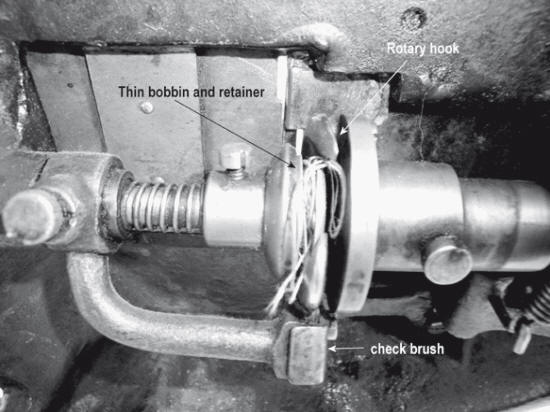

Figure 6

underside view showing rotary hook and bobbin assembly

The presser foot is pivoted at P (Fig. 5) and has the endearing characteristic that, if one raises it much with the needle down, it breaks the needle. The needle bar is driven from the ballshaped cam (E on Fig. 1) on the lower shaft. The left end of that shaft carries a small version of the early Wheeler & Wilson rotary hook, complete with check brush and thin disc bobbin held in place by a spring mounted cone (Fig. 6).

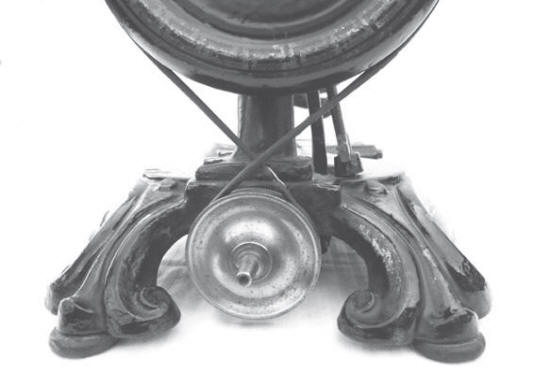

The bobbins were wound on the tapered end of the main shaft beyond the pulley. Fig. 7 shows the twisted belt drive. This reversed the direction of rotation of the shaft (as would happen with gearing) and, since it increased the length of belt in contact with the small pulley, reduced slippage.

Figure 7

he crossed-belt drive from the handwheel